7

Remove

powder

or debris

from

shelf

Problem Possible Cause Remedy

Primers not fully seated Lever not lowered to full down stop Actuate lever to FULL DOWN position

Die set too deeply to press Adjust dies to insure carrier can travel to

FULL UP position

Primer rocker arm bolt

not properly adjusted

See adjustment procedure in this manual

Tipped primer Case retainer out of adjustment See adjustment procedure in this manual

Cases not aligned well due to

out of tolerance or damaged rim

Install sizing die without decapper in priming

station for better alignment.

See Changing Dies, Station #2.

Dirt or gun powder in shell holder grooves Scrape shell holder grooves with paper clip. Use

compressed air to remove debris.

Tumbling media on primer post

or in primer feed

Remove and clean primer feed. Do not process

cases with tumbling media lodged in primer

flash hole.

Primer does not feed onto primer punch Oil in trough Clean oil from trough

Primer trough not full Keep primer trough full

Shell plate fails to index Damaged case ejector pawl Straighten pawl to prevent excessive

clockwise movement of shell plate

Carrier out of adjustment See adjustment procedure

in this manual

Indexer improperly installed See adjustment procedure

in this manual

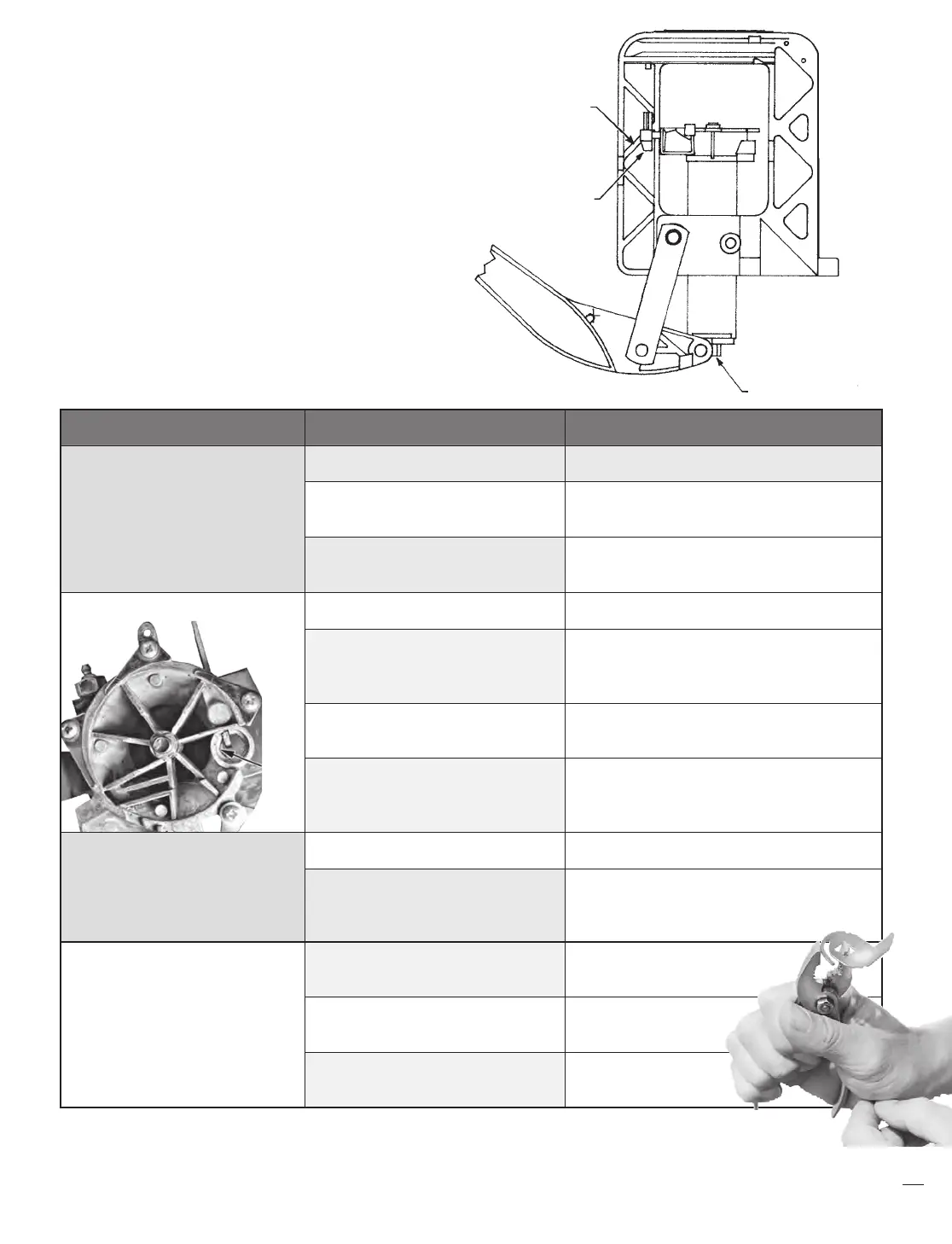

Alignment of the Carrier to the Turret

This is an adjustment that need never be done unless

you disassemble the carrier from the ram.

The draw bolt head, at the bottom of the ram,

MUST be loosened so the carrier can be rotated on

the end of the ram. With the index flipper in the “in

position” and the carrier at the pull out rib position,

swing the carrier clockwise (viewed from top) un-

til center hub of index flipper contacts the pull-out rib.

[

FIGURE 4]. Tighten draw bolt securely — 11.6 f./lbs.

Troubleshooting

PULL-OUT RIB

INDEX FLIPPER

DRAW BOLT

FIGURE 4

Loading...

Loading...