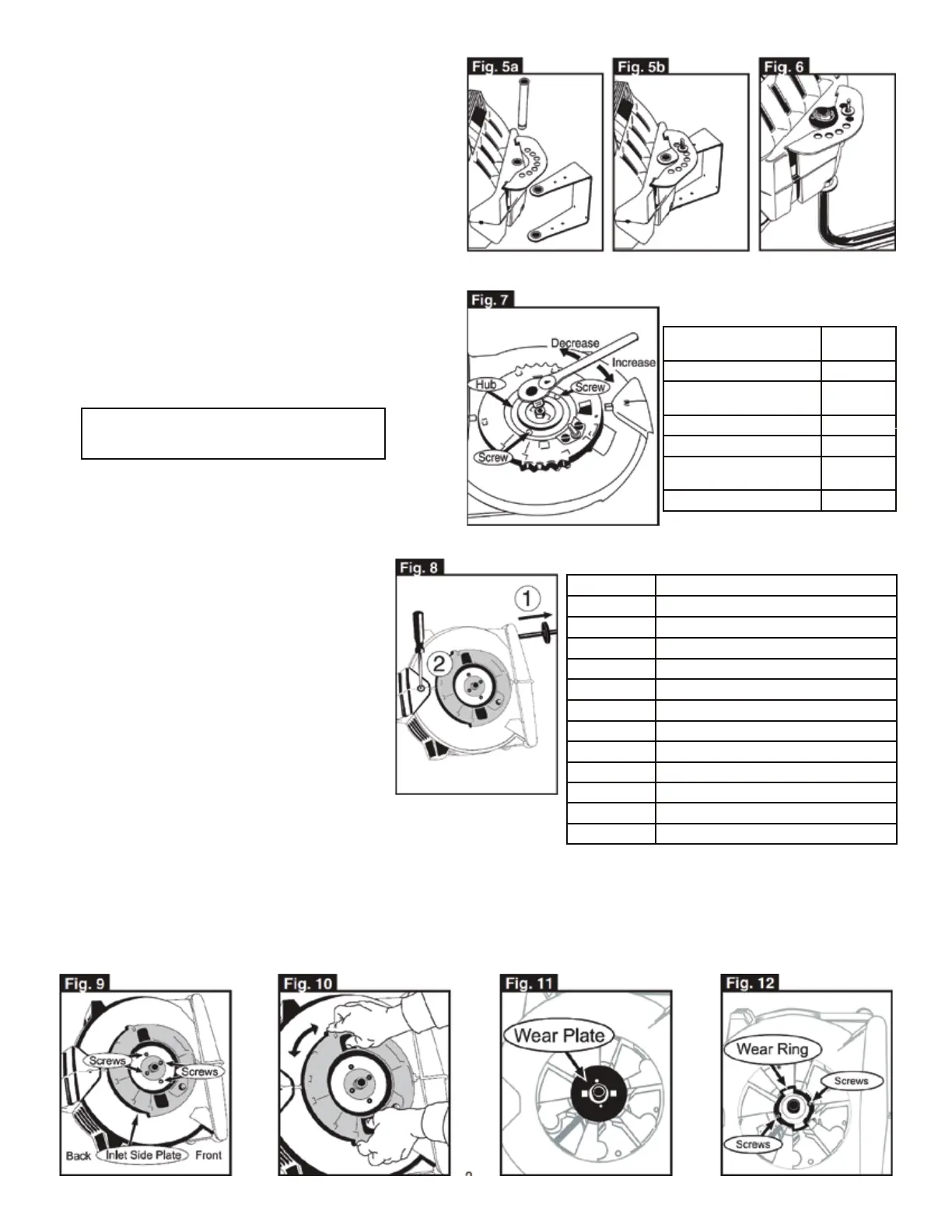

SEVEN POSITION LOCKING BRACE

LEVELWIND retractable hose reels can swing freely on bracket

or can be locked in one of seven positions, allowing for specific

mounting requirements.

Standard bracket

1) Remove bracket rod from reel (SEE FIG. 5A).

2) Place seven position locking brace over bracket so

that bracket rod holes are aligned. Replace bracket rod so that

brace, reel & bracket are attached. Insert hitch-pin clip through

end of bracket rod (SEE FIG. 5B).

3) Rotate bracket so that it is at desired angle & lock

into place with fastener (SEE FIG. 5B).

Maintenance Procedures

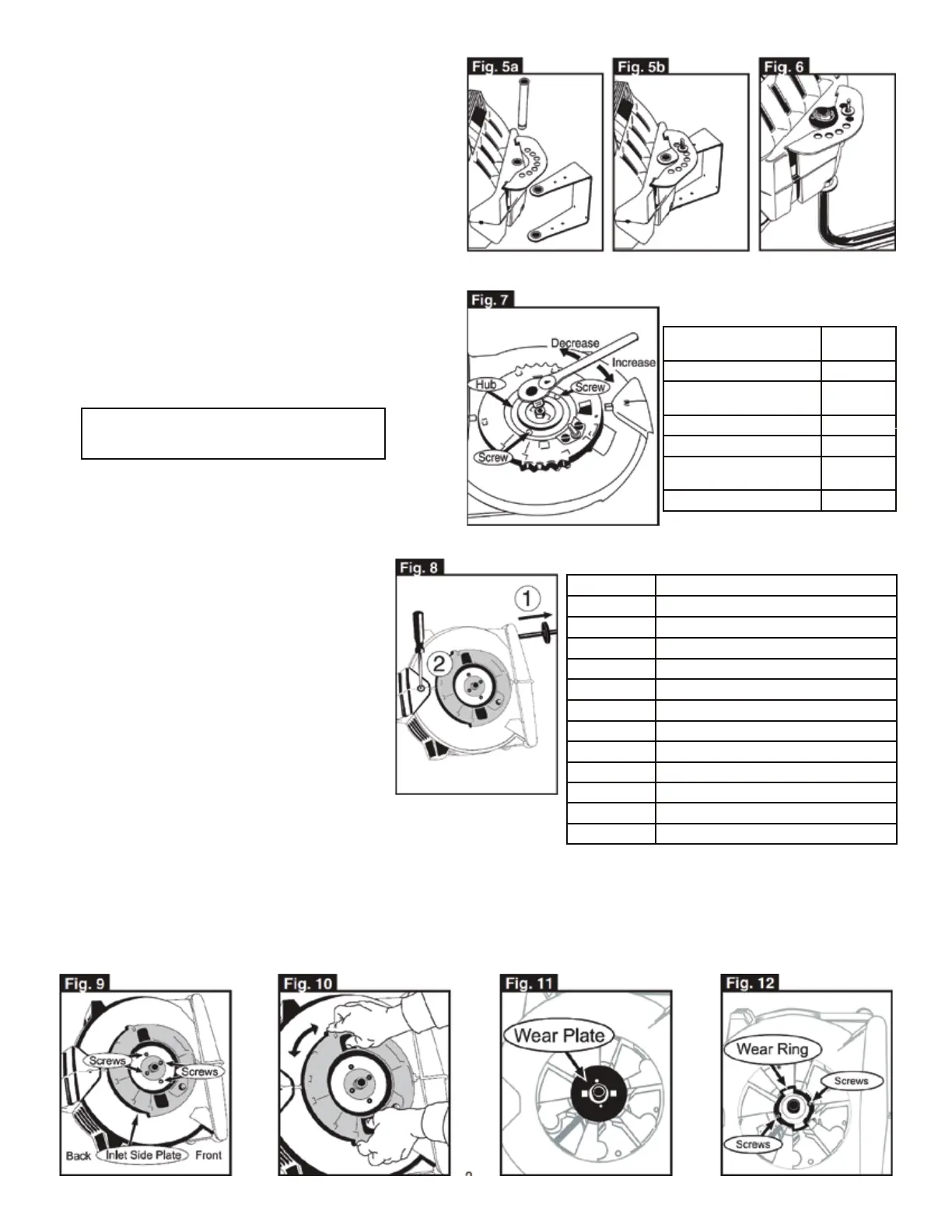

TENSION ADJUSTMENT:

This reel is preloaded with spring tension that is set at the factory.

If the reel becomes completely untensioned, please identify

your hose reel model number referenced in the Factory Preset

Tensioning Table to find out how many turns are needed for proper

tensioning. If a heavy air tool is attached to the end of the hose,

you may need to add tension to overcome the weight of this tool.

DO NOT EXCEED one full turn past the number of turns listed in

the Factory Preset Tensioning Chart below.

Levelwind

TM

Model # # of Tension

Turns

L8305 / L8305FZ 3

L8306 / L8306FZ / L8306-EU 5

L8340FZ

L8310 / L8310-EU 4

L8335 / L8335FZ / L8335-EU 4

L8344 / L8345 / L8346 /

L8349

4

L8350 11

TOOLS REQUIRED:

Phillips Screw Driver, 3/4 in. Socket Wrench

1) Lay reel on its side (SEE FIG. 7).

2) Place wrench on hub fitting plate nut. HOLD WRENCH

FIRMLY.

3) Unscrew hub. DO NOT REMOVE SIDEPLATE.

4) Turn wrench either ½ turn or no more than one full turn.

Turn clockwise to increase tension. Turn counterclockwise

to decrease tension.

5) Replace hub plate screws and tighten. Return reel to

mounting bracket.

Factory Preset Tensioning Table

HOSE REPLACEMENT:

To ensure proper performance, please consult the Hose

Replacement Kit table for the appropriate part number

to order. Call 1(800) 645-8258 to order kit.

Replacement Hose Kits

1) Pull entire length of hose out of reel (SEE FIG. 8).

2) While entire length of hose is out of the reel, place long

screw driver (3/8 in. in diameter (9 mm)) all the way

though the hole located at the back portion of reel. This

eliminates any chance for the reel to retract while replac-

ing hose.

Sideplate removal

3) Locate inlet sideplate. Remove four f

While placing fingers

grooves located on the top and bottom of sideplate, depress locking tabs at the same

time with thumbs (SEE FIG. 10). Rotate side plate either way until sideplate unlocks.

Remove sideplate.

4) Remove wear plate (SEE FIG. 11).

wear ring (SEE FIG. 12).

Model # Description

RP005005 Replacement Hose Assembly for L8305

RP005006 Replacement Hose Assembly for L8306

RP005006-EU Replacement Hose Assembly for L8306-EU

RP005008 Replacement Hose Assembly for L8310

RP005035 Replacement Hose Assembly for L8335

RP005023 Replacement Hose Assem

RP005035-FZ Replacement Hose Assembly for L8335FZ

bly for L8344

RP005069 Replacement Hose Assembly for L8345, L8350

RP005049 Replacement Hose Assembly for L8349, L8346

RP005040-FZ Replacement Hose Assembly for L8340FZ

RP005005-FZ Replacement Hose Assembly for L8305FZ

RP005006-FZ Replacement Hose Assembly for L8306FZ

Replacement Hose Kits

asteners (SEE FIG. 9). While placing fingers on

Unscrew two fasteners on wear ring and remove

Optional Bench/High Wall

Mounting Bracket

(see FIG. 6)

Loading...

Loading...