A1

7

Stopping

all

Engines

The engine should be allowed to slow idle for approximately

2

minutes before stopping, especially after extended

periods of full load and full speed operation. This is particularly important

in

the case

of

turbocharged engines.

Fuel

System

CAUTION: Your injection pump is a very accurately machined piece of equipment and requires careful handling

and adjustment. No repairs other than shown herein should be entrusted to other than a diesel repair facility having

the required tools, knowledge and

tesVcalibration equipment.

CAUTION: Never bend the injection pipes (which connect injection pump to injectors) as this may unbalance the

volume of fuel delivered to each cylinder.

CAUTION:

Do

not use a galvanized fuel tank as the zinc coating reacts with the fuel oil and forms undesirable

compounds which can foul the injection system.

The fuel

injecton equipment is made to very accurate limits and therefore, even the smallest particle of dirt entering

the system will destroy its efficiency by causing blockage or scoring or premature wear on highly finished parts.

A

clean fuel system is absolutely essential. Insure scrupulous cleanliness when handling fuel or fuel system compo

-

nents. At all times make certain that water is not allowed to contaminate the fuel oil. Try to make a practice ofrefueling

out of the rain. Use a fine gauze filter funnel and always wipe the fuel tank around the filter cap before

andafter

filling and immediately replace the cap.

An efficient, large size primary fuel filter and water separator (coalescer) is deemed a necessity in order to prevent

foreign particles reaching the injection equipment on your engine.

Your engine is equipped with secondary fuel filters which filter out contaminates that may find their way through

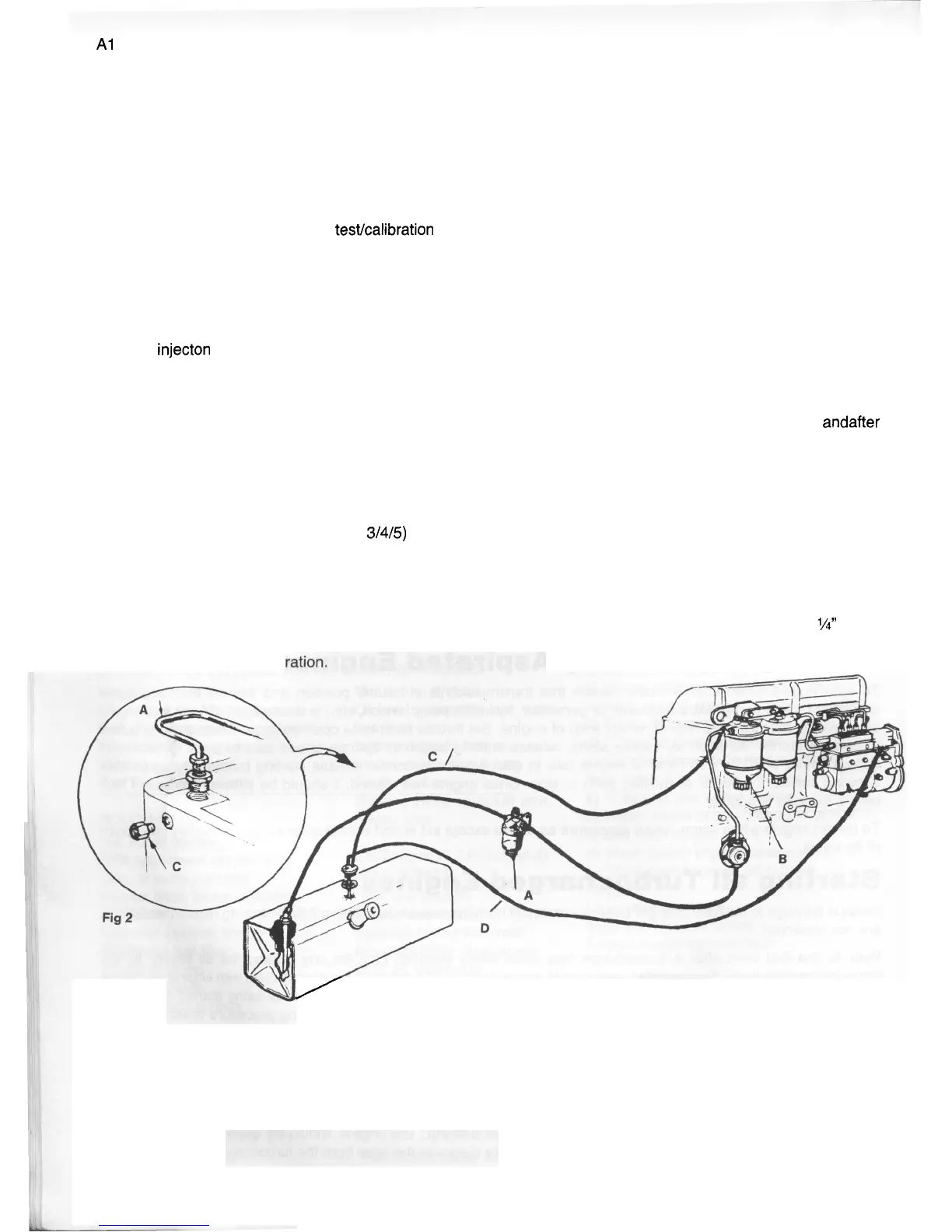

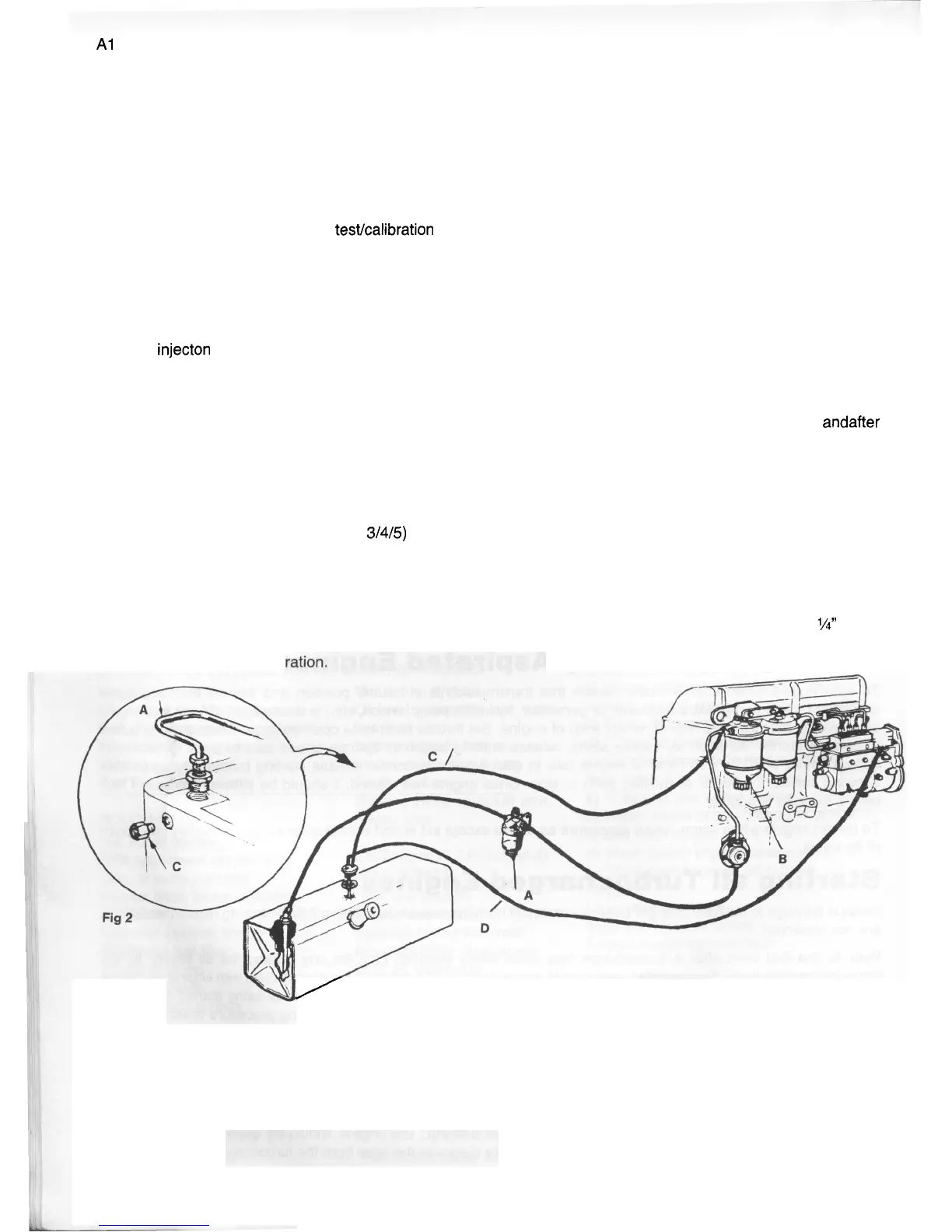

the primary filter. These filters (see Fig.

3/4/5)

located towards rear of engine block, right side, have elements which

should be replaced once each season or at least each

200

hours (which ever comes first) under normal conditions.

(When replacing filters, use new gaskets or sealing rings to prevent air leaks.) Following filter replacement, blead

air from fuel system as later described under “bleeding the fuel system”. Excess fuel delivered to the injectors by

the injection pump is collected by a tube located under the rocker arm cover (see A, Fig.

2)

and delivered to fitting

C, Fig.

4

located at rear, right side of cylinder head. This fitting should be connected to top of fuel tank by

1/4”

(min.)

fuel line. It is recommended that the Boat Builders installs a short section of flexible tubing in this line to prevent

breakage due to engine vib

/

FIG.

3

TYPICAL FUEL SYSTEM, NATURALLY ASPIRATED ENGINES

A

-

Primary fuel filter water separator

B

-

Secondary fuel filter

C

-

Excess fuel return tube

D

-

Injection pump return tube

NOTE: All N/A Engines are fitted

with a common fuel return

line C

D.

Loading...

Loading...