88

ROUTER TABLE OPERATION

R9PLUS Joinery System User Guide

Making The Beam

Chapter 1

A

C

D

B

A

B

B

A

5

/

16

"

1

7

/8

"

5/1

6

"

dia.

x 5/

1

6

"

deep

4

1

/

2

"

[114mm]

[8mm]

[47mm]

[8mm x 8mm]

A

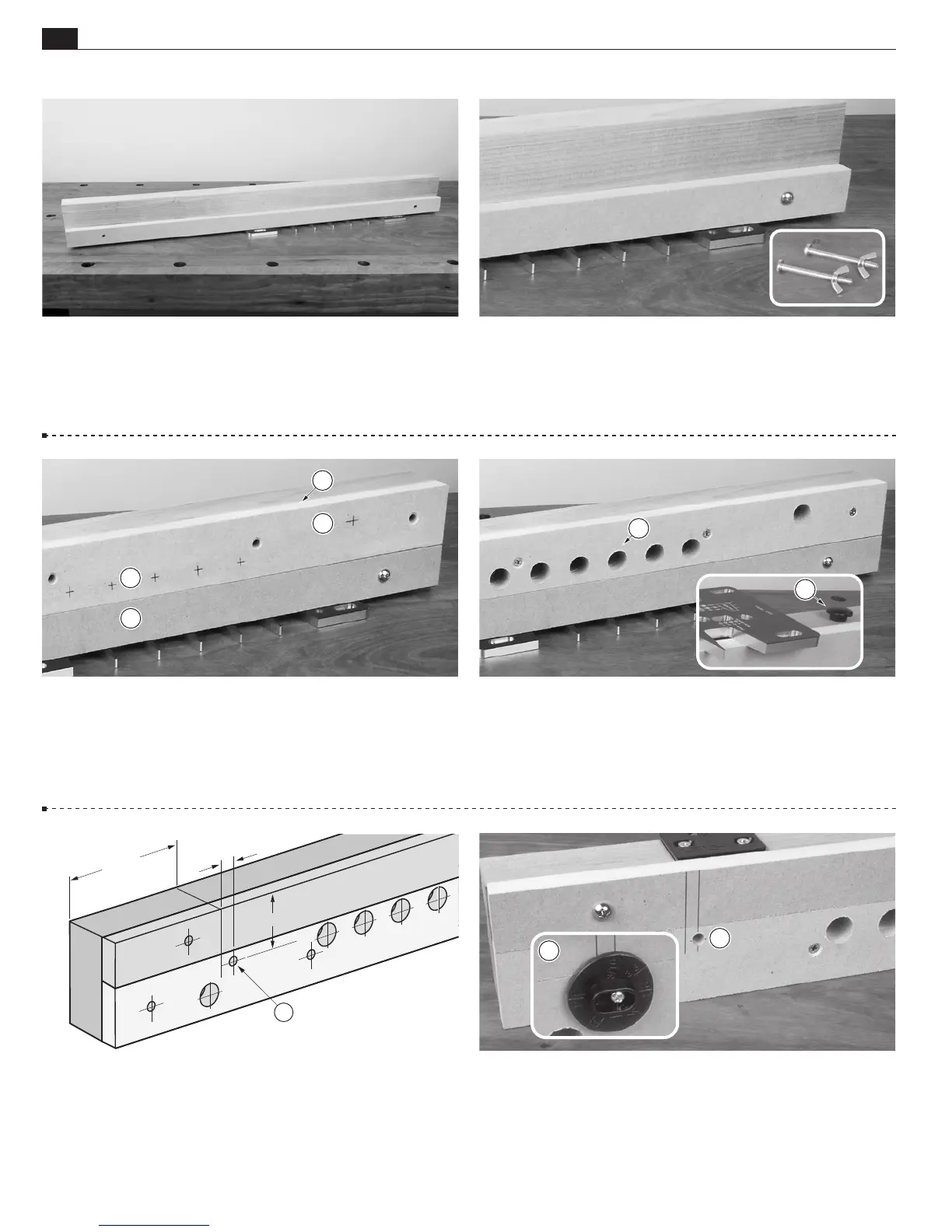

1-13 Turn the assembly upside down. Take a piece of the

predrilled sacrificial board and lay it flush on the template.

1-15

Place the clamping surface

against the beam

. Be sure

the clamp hole layout marks

are next to the sacrificial board

.

Screw the clamping surface to the beam through the countersunk

holes.

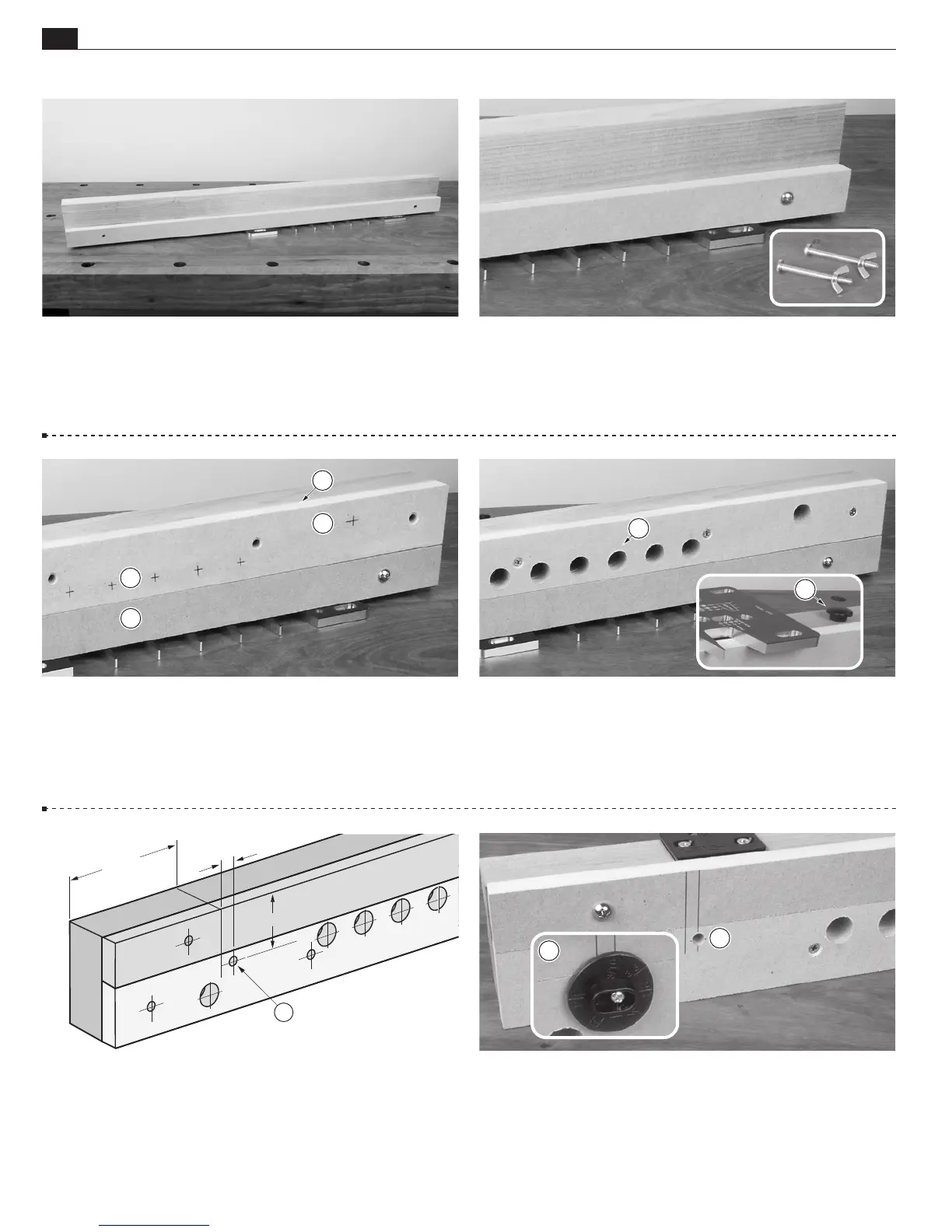

1-17 Side Stop Positioning Create layout lines as indicated

above for the sidestop

. Note: Be precise. Side stop positioning

is very important.

1-14 Using the two

5

⁄16"[8mm] holes as drill guides, drill

two

5

⁄16"[8mm] holes through the beam. Attach the sacrificial

board at the left end with a ¼-20 machine screw and wing nut.

Then move the template to its second position and install the

second screw.

1-16

Clamp Holes Drill all

3

⁄

4

"[19mm] clamp holes

square

to the beam, through the clamping surface and beam. Next,

drill two holes (as per beam drawing),

5

⁄16"[8mm] diameter and

9

⁄16"[14mm] deep, for the table glide

(used for router table

operation only).

1-18 Using a Brad Point or Forstner bit, counter bore a

5

⁄16"[8mm] hole

,

3

⁄8"[9,5mm] deep for the side stop hub.

Then, using a

3

⁄32"[2,5mm] bit, drill a pilot hole for the side

stop mounting screw. Attach the side stop to the beam with the

provided No.8 x 1

1

⁄4"[30mm] round head screw

.

Loading...

Loading...