Page 6

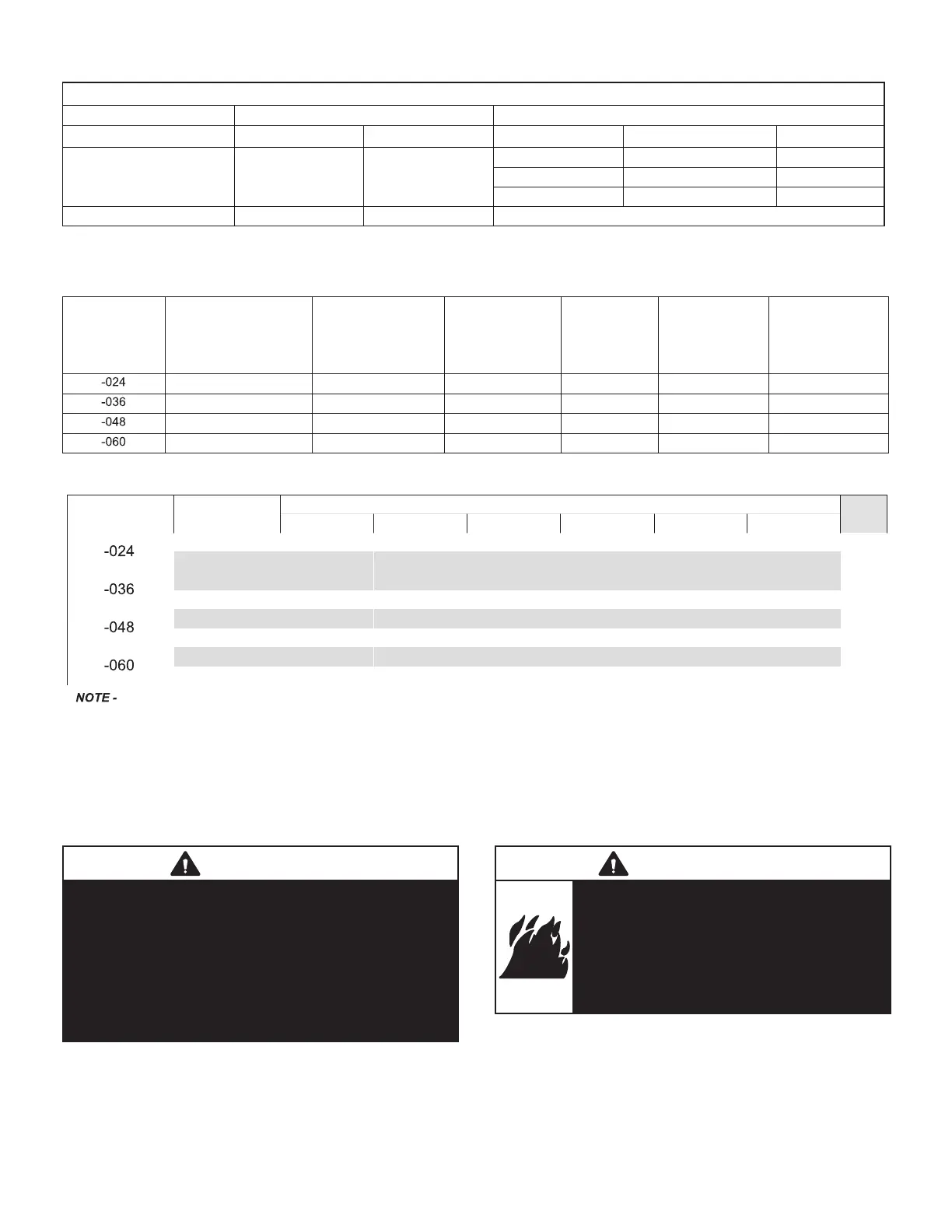

TABLE 1. Standard Refrigerant Line Set – Up to 50 Linear Feet

Inches (mm)

Valve Size Connections Recommended Line Sets

SL28XCV*

Liquid Line Suction Line L15 Line Set Model Line Set Length Catalog Number

-024

L15-65-30 30 feet (9.1 m) 89J60

-036

-048

3/8” (10 mm)

7/8” (22 mm)

L15-65-40 40 feet (12.2 m) 89J61

L15-65-50 50 feet (15.2 m) 89J62

-060 3/8” (10 mm) 1-1/8” (29 mm) ** Field-fabricated

* Applicable to all minor revision numbers unless otherwise specified.

** Some applications may require a field-provided 1-1/8” to 7/8” adapter.

TABLE 2. SL28XCV Line Set Guidelines – Between 51 - 150 Feet Linear Length

Model

Maximum Total

Equivalent Length (ft)

Maximum Linear

(actual) Length (ft)

Maximum Vapor

Riser (ft)

Maximum

Linear Liquid

Lift (ft)

Preferred

Vapor Line

Sizes for

Horizontal

Runs

Required Vapor

Riser Size

180 150 60 60 7/8” 5/8”

180 150 60 60 7/8” 3/4”

180 150 60 60 7/8” 7/8”

180 150 60 60 7/8” 7/8”

TABLE 3. Liquid Line Diameter Selection Table

Unit Line Size

Total Linear Length (feet)

25 50 75 100 125 150

5/16”

25

50 55 48 40 33

Max. Elevation

(ft)

3/8”

25

50 60 60 60 60

3/8”

25

50 60 56 51 45

1/2”

25

50 60 60 60 60

3/8”

25

50 50 41 31 22

1/2”

25

50 60 60 60 60

3/8”

25

50 36 22 8 NR

1/2”

25

50 60 60 60 59

Shaded rows indicate rated liquid line size

A. Find your unit on the left side of the table.

B. Start with the rated liquid line size (shaded row) on the outdoor unit

C. Select the actual To tal Linear Length of your system shown at the top of the table.

D. The elevation listed in the table is the maximum allowed for the liquid line listed.

E. Select or consider the larger liquid line size shown in the table if the elevation does not meet your requirements.

NOTE - For new or replacement line set installation, refer to Service and Application Note - Corp. 9112-L4 (C-91-4).

CAUTION

Brazing alloys and ux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing operations.

Perform operations only in well-ventilated areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and ux.

WARNING

Danger of re. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing torch

to a pressurized system may result in ignition

of the refrigerant and oil mixture. Check the

high and low pressures before applying heat.

Loading...

Loading...