Page 46

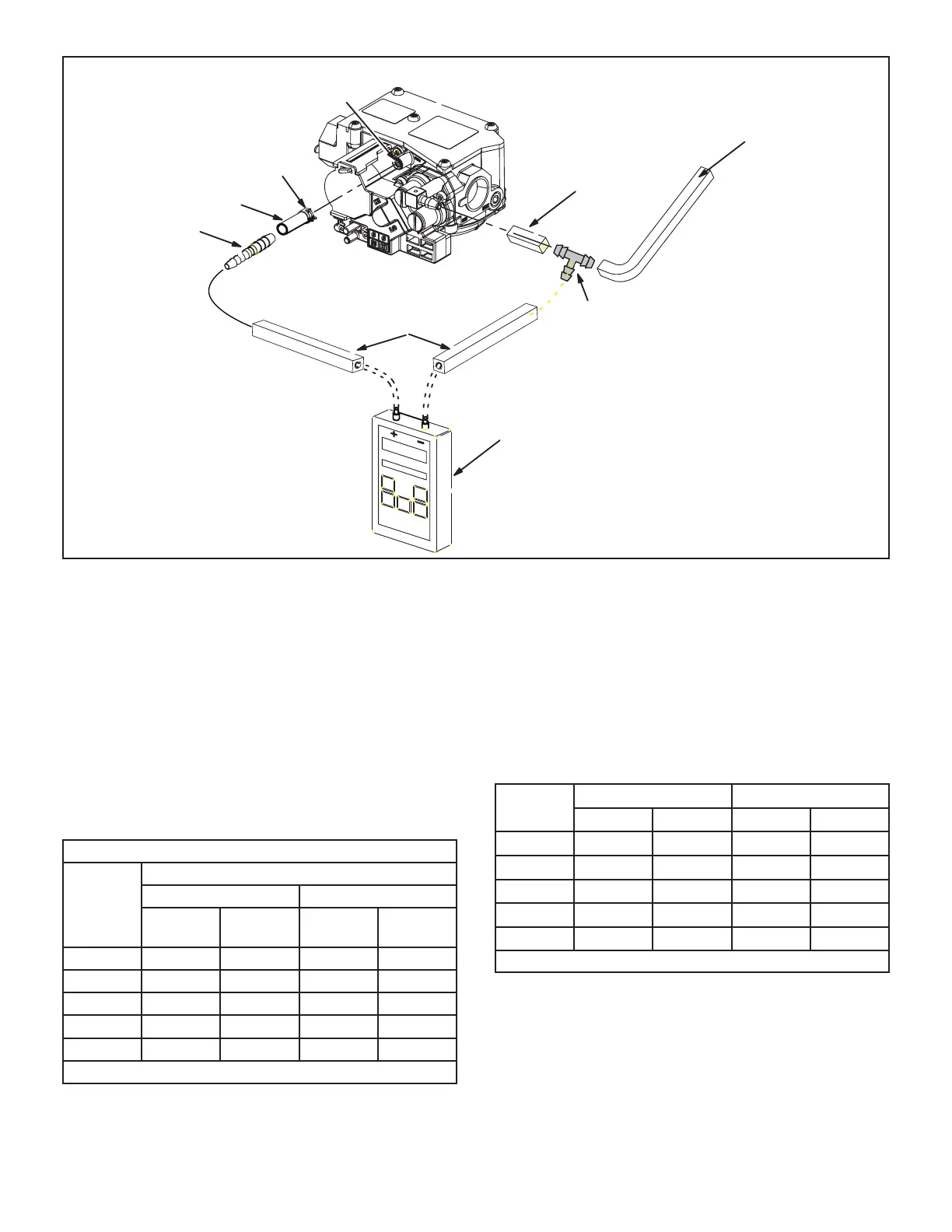

MANIFOLD PRESSURE CHECK SET UP

Manifold Post

Clamp

5/16” Round

Hose

Reducer

Fitting

10” Long

Square

Tubing

2” Long

Square Tubing

Tee

Gas Valve Regulator

Vent Hose

(to burner box)

Measuring Device

Figure 52

F- Proper Gas Flow (Approximate)

Furnace should operate at least 5 minutes before check-

ing gas ow. Determine time in seconds for two revolu-

tions of gas through the meter. (Two revolutions assures a

more accurate time.) Divide by two and compare to time

in table 21 below. If manifold pressure matches table 21

and rate is incorrect, check gas orices for proper size and

restriction.

NOTE- To obtain accurate reading, shut o all other gas

appliances connected to meter.

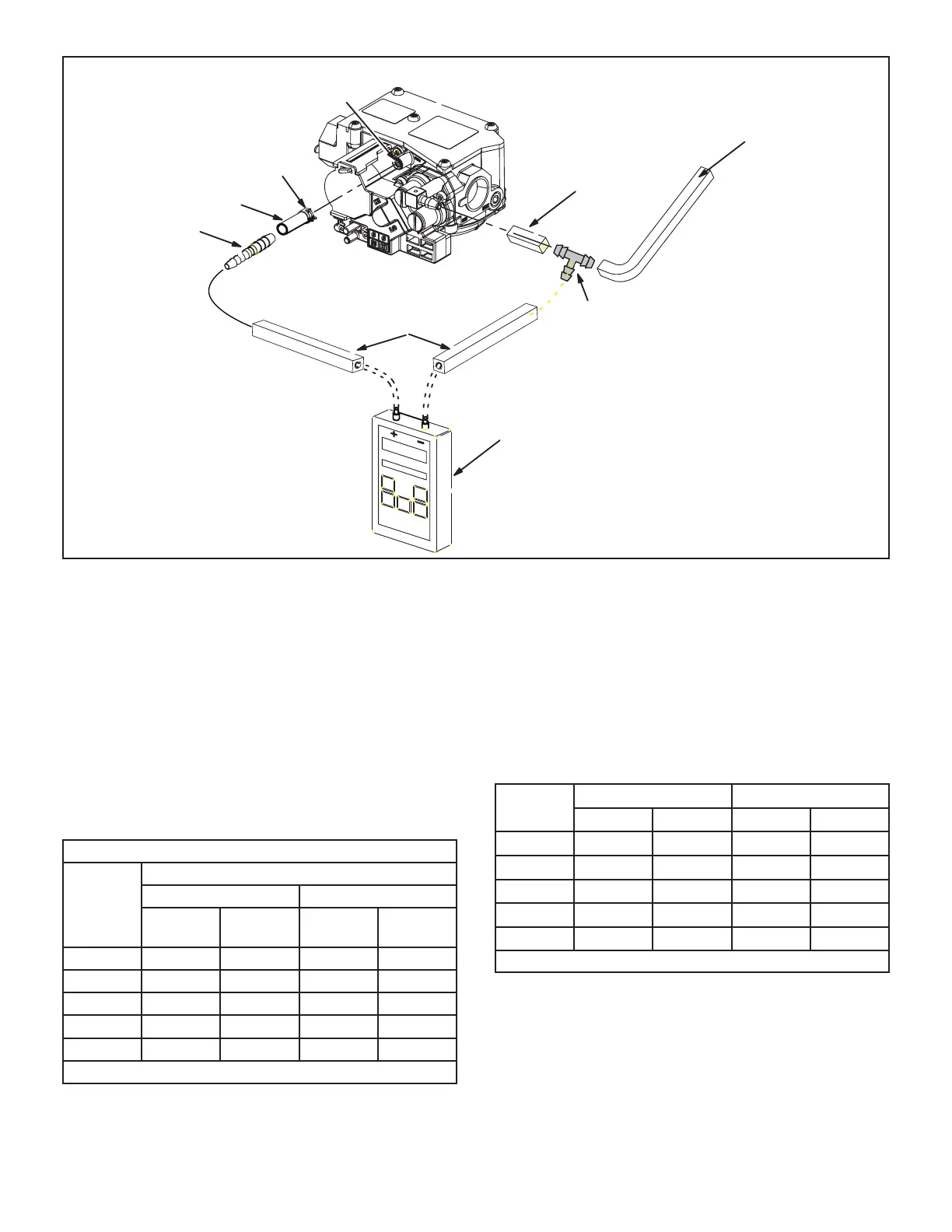

TABLE 21

GAS METER CLOCKING CHART

EL296

Unit

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-045 80 160 200 400

-070 55 110 136 272

-090 41 82 102 204

-110 33 66 82 164

-135 27 54 68 136

Natural-1000 btu/cu ft LP-2500 btu/cu ft

G- Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking com-

bustion. See sections E- and F-. Take combustion sample

beyond the ue outlet. Table 22 shows acceptable com-

bustions. The maximum carbon monoxide reading should

not exceed 100 ppm.

TABLE 22

EL296

Model

CO

2

% For Nat CO

2

% For L.P

Low Fire High Fire Low Fire High Fire

045 5.4 - 6.4 7.5 - 8.5 6.4 - 7.4 8.8 - 9.8

070 5.3 - 6.3 7.4 - 8.4 6.3 - 7.3 8.7 - 9.7

090 5.8 - 6.8 7.6 - 8.6 6.8 - 7.8 8.9 - 9.9

110 6.1 - 7.1 8.0 - 9.0 7.1 - 8.1 9.3 - 10.3

135 6.1 - 7.1 7.8 - 8.8 7.1 - 8.2 9.1 - 10.1

The maximum carbon monoxide reading should not exceed 100ppm.

H- High Altitude

The manifold pressure, gas orice and pressure switch

may require adjustment or replacement to ensure proper

operation at higher altitudes. See table 23 or 24 for man-

ifold pressures and table 25 for gas conversion and pres-

sure switch kits.

Loading...

Loading...