How to fix failed burner motor in Lennox Furnace?

- AAngelica MartinezSep 4, 2025

If the burner motor is failed in your Lennox Furnace, replace the motor.

How to fix failed burner motor in Lennox Furnace?

If the burner motor is failed in your Lennox Furnace, replace the motor.

How to fix air leak in oil supply line of Lennox Furnace?

If you have an air leak in the oil supply line of your Lennox Furnace, locate and correct the leak.

What to do if Lennox ELO183UF has a blown fuse or tripped circuit breaker?

If your Lennox Furnace has a blown fuse or tripped circuit breaker, replace the fuse or reset the circuit breaker.

What to do if flame detector is exposed to light in Lennox ELO183UF Furnace?

If the flame detector is exposed to light in your Lennox Furnace, seal off the false source of light.

What to do if flame detector leads are shorted in Lennox Furnace?

If the flame detector leads are shorted in your Lennox Furnace, separate the leads.

What to do if Lennox ELO183UF has low line voltage?

If you have low line voltage in your Lennox Furnace, check the voltage at the power source and correct the cause of the voltage drop or call the power company.

What to do if Lennox ELO183UF oil pressure is too low?

If the oil pressure of your Lennox Furnace is too low (less than 140 psi), increase the oil pressure to 140 psi.

How to fix kinks or restriction in oil line of Lennox Furnace?

If your Lennox Furnace has kinks or restrictions in the oil line, repair or replace the oil line.

How to fix nozzle orifice plugged in Lennox Furnace?

If the nozzle orifice in your Lennox Furnace is plugged, replace the nozzle with one of the same size, spray angle, and spray pattern.

What to do if Lennox ELO183UF pump loses prime – air slug?

If the Lennox Furnace pump loses prime due to an air slug, prime the pump at the bleed port.

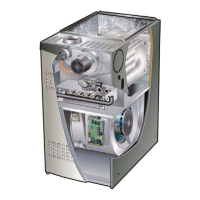

Provides detailed measurements, diagrams, and key specifications for the unit.

A crucial checklist for ensuring proper initial operation and performance verification.

Outlines essential conditions, codes, and standards for installing the furnace.

Specifies minimum distances required around the unit for safety and service access.

Details specific air volume needs for combustion based on installation location and type.

Instructions for positioning and ensuring the unit is level for proper function.

Procedures for fine-tuning the burner and setting the oil nozzle for optimal performance.

Critical instructions for safely venting combustion byproducts.

Guidance on positioning the indoor coil in heating/cooling applications.

Procedures and safety notes for connecting the furnace to the venting system.

Guidelines for selecting tubing size and installing the oil supply line.

Steps for connecting the oil supply line and installing filters.

Instructions for proper electrical connections and safety precautions.

A schematic illustrating the electrical connections for the unit.

Steps for initiating operation and making initial adjustments.

Detailed instructions for safely starting the oil burner assembly.

Essential procedures for tuning the burner for efficiency and preventing sooting.

General guidance for servicing, including filter checks and replacement.

Procedures for cleaning the internal heat exchanger components.

Details on the Beckett Genisys™ 7505B primary burner control, its buttons, and lights.

Describes the furnace's operational steps during a heating call.

General introduction to diagnosing and resolving furnace operational issues.

Lists system responses to various fan operating conditions and potential issues.

Guides on diagnosing why the burner will not initiate operation.

Steps to diagnose issues when the burner starts but fails to establish a flame.

Diagnosing reasons for burner lockouts due to safety controls.

Steps to resolve flame loss leading to safety lockouts.

Diagnosing causes for the burner cycling on and off too frequently.

Steps to resolve issues where the burner runs constantly without reaching setpoint.

Diagnosing causes for continuous burner operation resulting in insufficient heat.

Loading...

Loading...