# 45466K003 Page 11

Upflow Models G1D91BU, G1D93BU, & CG90UB

Non-Direct Vent Installation

An inlet air restrictor plate (see Figure 1 on page 5) is

supplied with this furnace and can be found in the plastic

bag containing these Installation Instructions and the

User’s Information Manual. This restrictor plate is to be

used only in non-direct vent applications. Attach a 90°

elbow (not supplied) to the inlet coupler and install the

restrictor plate inside the elbow in all non-direct vent

installations (see Figures 8 and 9).

The flue pipe screen (see Figure 1 on page 5) should be

installed at the termination of the flue pipe and is designed

to keep objects out of the flue pipe.

Prime the trap system by slowly pouring 1 cup of water

down the vent pipe.

For horizontal venting, refer to Figure 8. For vertical

venting, refer to Figure 9. The vent pipe on horizontal runs

must slope upward, away from the furnace, at a minimum

pitch of 1/4" per foot of run, to prevent accumulation of

condensate.

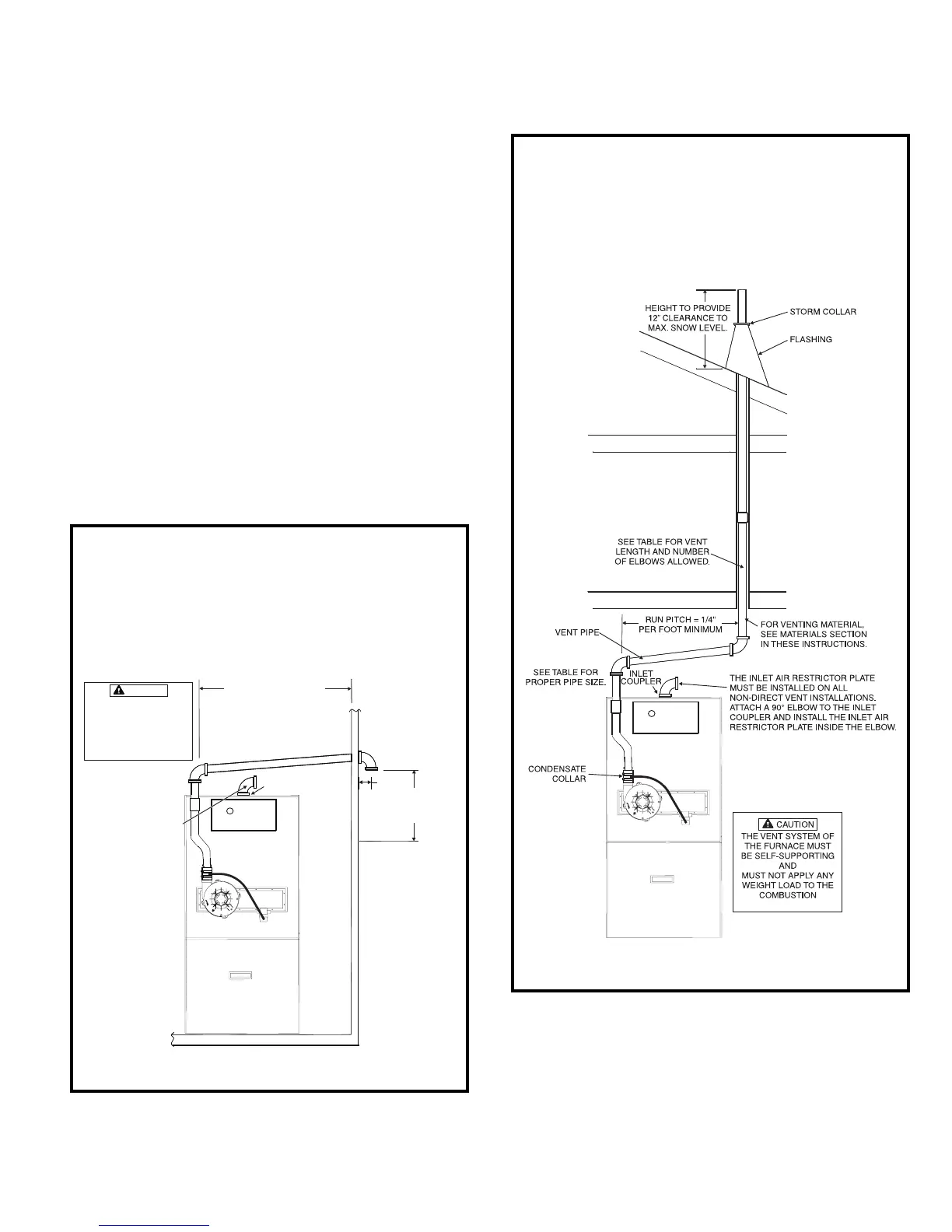

Figure 8

Upflow Non-Direct Vent

Horizontal Venting

(Models G1D91BU, G1D93BU,

& CG90UB Only)

(CLOSED)

DRAINHOLE

THRU.

59.69/56.64

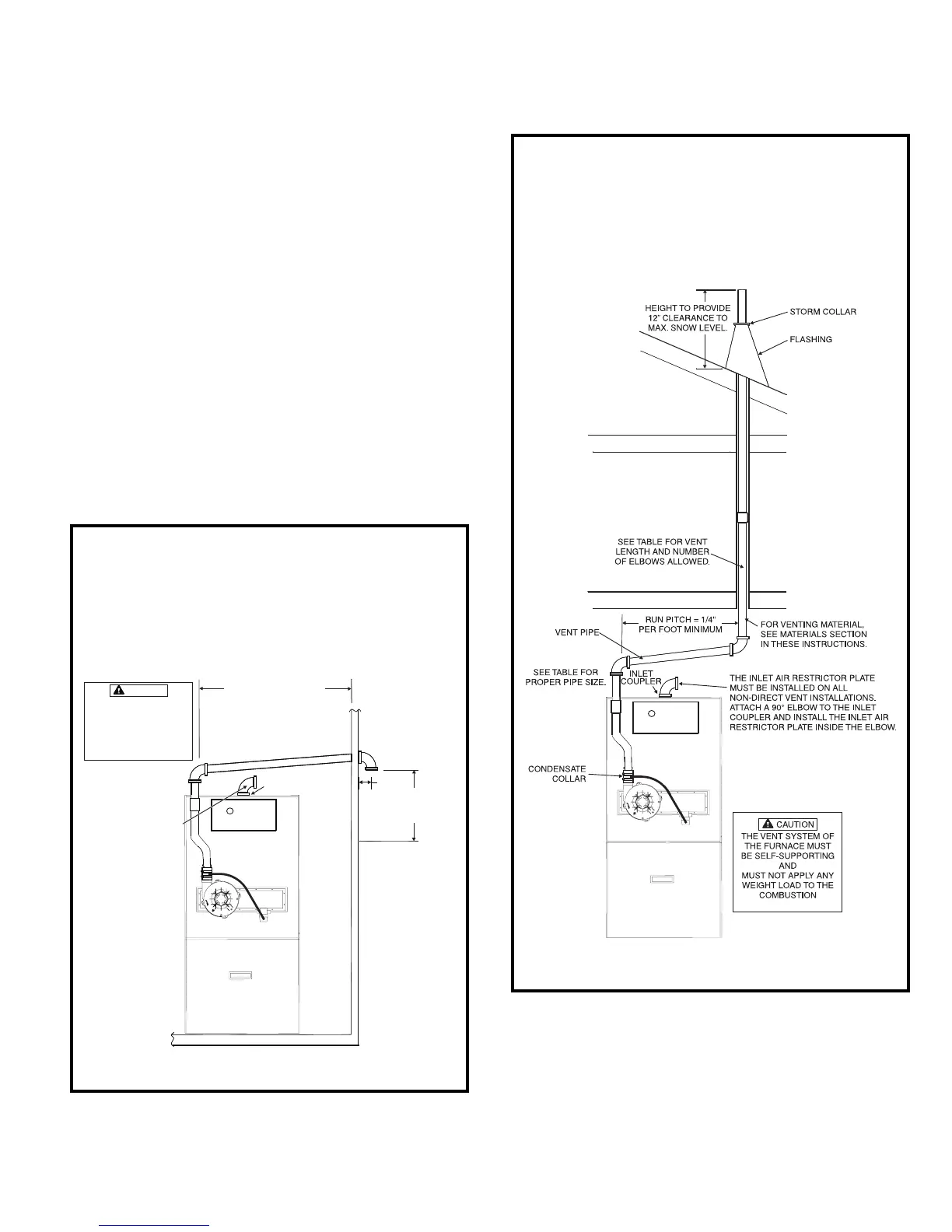

THE VENT SYSTEM OF

THE FURNACE MUST BE

SELF-SUPPORTING AND

MUST NOT APPLY ANY

WEIGHT LOAD TO THE

COMBUSTION BLOWER.

CAUTION

SEE TABLE FOR

PROPER PIPE SIZE.

RUN PITCH = 1/4

PER FOOT MIN.

"

HEIGHT TO PROVIDE

12 CLEARANCE TO

MAX. SNOW LEVEL.

"

6"

CONDENSATE

COLLAR

THE INLET AIR

RESTRICTOR PLATE

MUST BE INSTALLED

ON ALL NON-DIRECT

VENT INSTALLATIONS.

ATTACH A 90° ELBOW

TO THE INLET COUPLER

AND INSTALL THE INLET

AIR RESTRICTOR PLATE

INSIDE THE ELBOW.

INLET

COUPLER

Upflow Non-Direct Vent

Vertical Venting

(Models G1D91BU, G1D93BU,

& CG90UB Only)

Figure 9

On initial start-up of the unit, some of the water used to

prime the trap system may run down into the combustion

blower and cause noise.

Loading...

Loading...