# 45464K003Page 12

(see Figure 15). The screws must be re-installed in the

vest panel after the inserts are removed.

Gas supply piping should be installed in accordance with

local codes and the regulations of the utility. Piping must be

of adequate size to prevent undue pressure drop. Consult

the local utility or gas supplier for complete details on special

requirements for sizing gas piping.

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use

a connector which has previously serviced another gas

appliance.

Pipe connections must be tight, and a non-hardening pipe

compound resistant to liquefied petroleum gases should

be used.

Connect gas pipe to furnace controls providing a ground joint

union as close to the controls as is possible to facilitate

removal of controls and manifold. Provide a drip leg on the

outside of furnace. A manual shutoff valve shall be installed

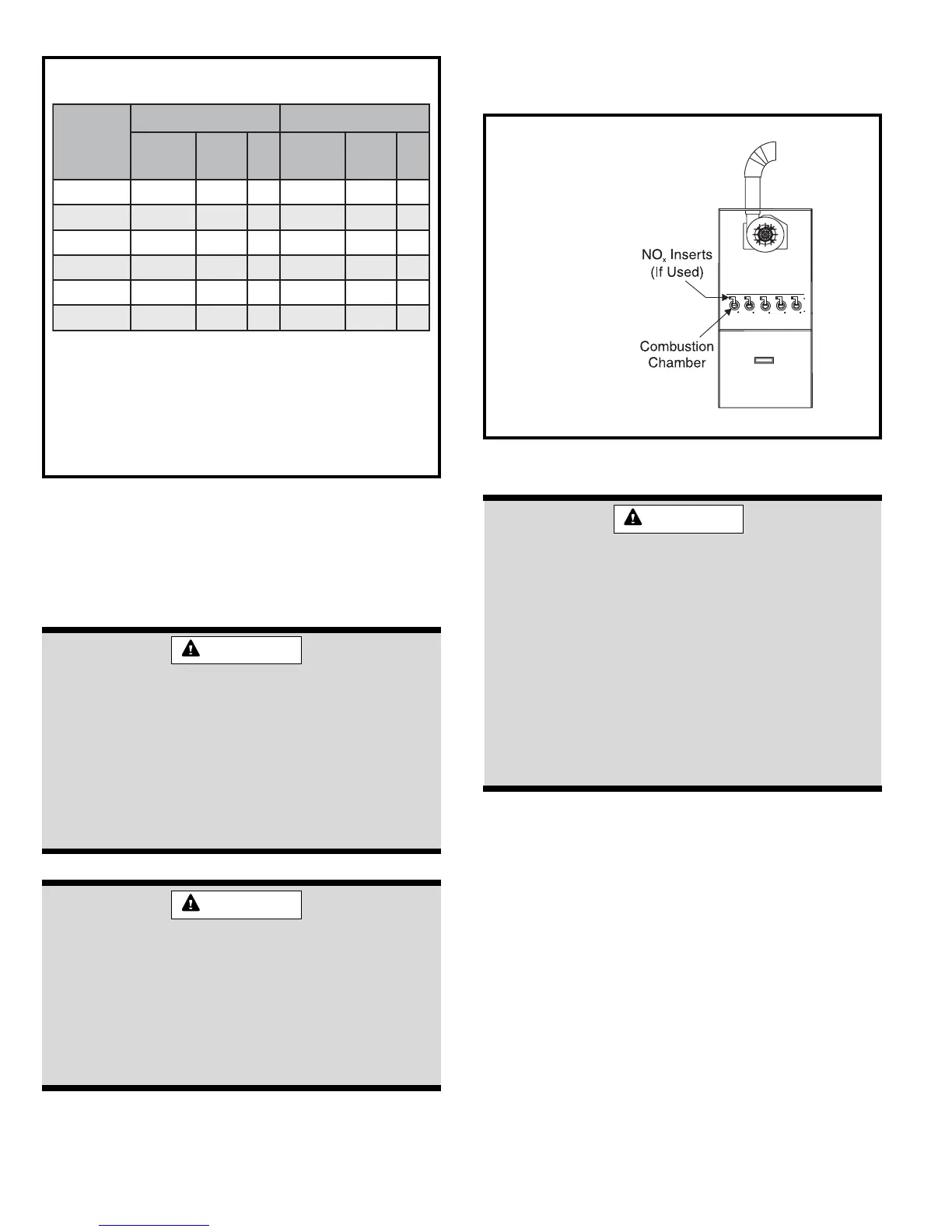

To remove the NO

x

inserts, first take out the burners. After

removing the burners, remove the screw holding each

insert and pull the insert from the combustion chamber

When converting a low NO

x

furnace (desig-

nated by an “L” in the model number, such as

G1N80BU100D20CL-1A) to propane, the

NO

x

inserts must be removed. Failure to

remove the inserts can create a situation

where carbon monoxide is produced which

may lead to asphyxiation.

WARNING

Any conversion of a natural gas unit to pro-

pane gas must be done by qualified person-

nel using a conversion kit available from the

manufacturer, following the instructions in the

conversion kit. If done improperly, overfiring of

the burners and improper burner operation

can result. This can create carbon monoxide

which could cause asphyxiation.

WARNING

NO

x

Insert

Location

Figure 15

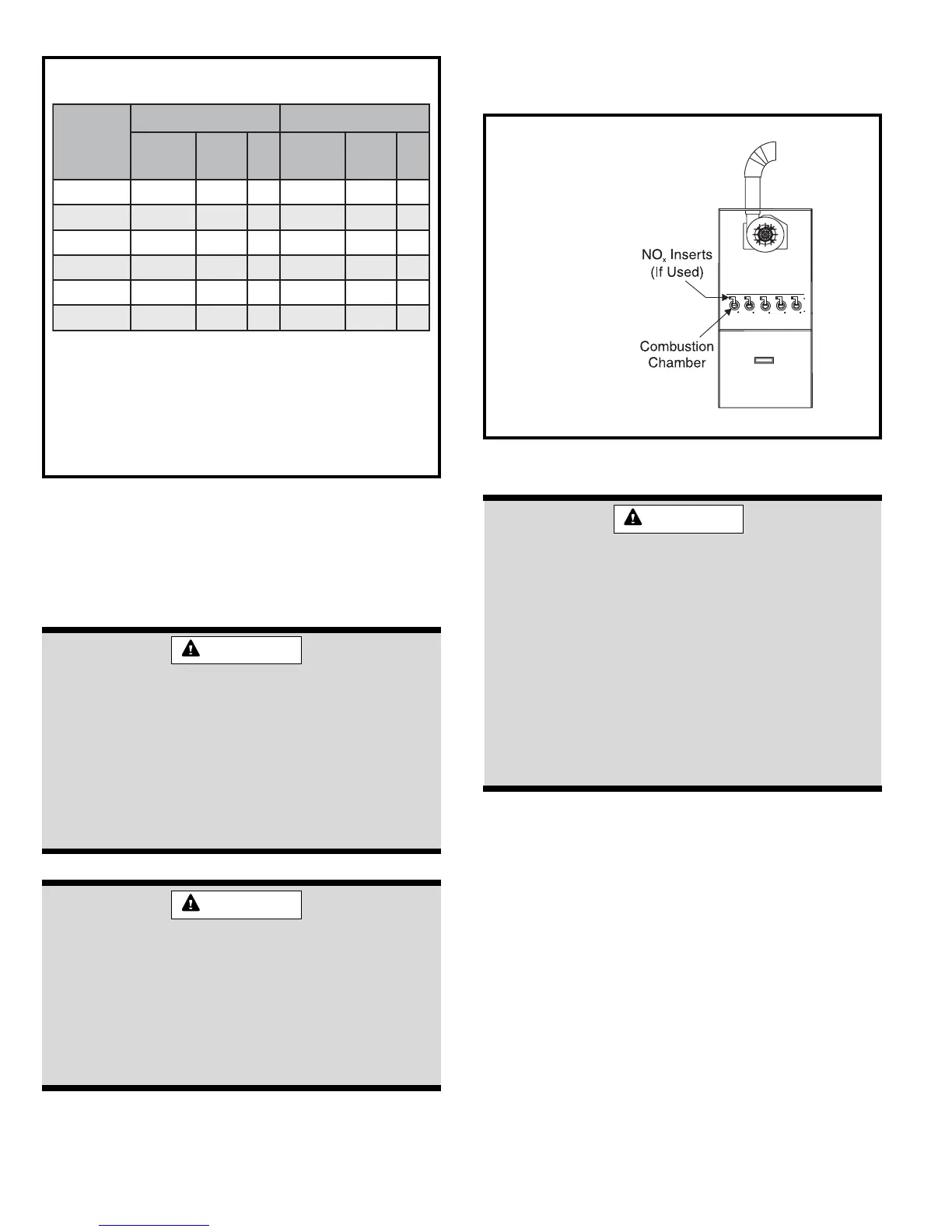

Table 1

Minimum Filter Requirements

1. The Airflow Descriptor is the two digits following the “D” in

the model number.

2. Areas and dimensions shown for permanent filters are

based on filters rated at 600 feet per minute face velocity.

3. Typical filter sizes are shown; however, any combination

of filters whose area equals or exceeds the minimum

area shown is satisfactory.

wolfriA

rotpircseD

sretliFelbasopsiD sretliFtnenamreP

aerA.niM

).ni.qs(

eziS

).ni(

.ytQ

aerA.niM

).ni.qs(

eziS

).ni(

.ytQ

90084

52x02

1042

02x61

1

01 084

52x02

1 042

02x61

1

21675

02x61

2882

02x61

1

41 276

02x02

2 633

02x02

1

61867

02x02

2483

02x02

1

22,02 069

52x02

2 084

52x02

1

Gas Supply and Piping

Refer to the furnace rating plate to make sure the furnace

is equipped to burn the gas supplied (natural or propane).

Failure to follow the safety warnings exactly

could result in serious injury, death, or prop-

erty damage.

Never test for gas leaks with an open flame.

Use a commercially available soap solution

made specifically for the detection of leaks to

check all connections. A fire or explosion may

result causing property damage, personal

injury, or loss of life.

WARNING

FIRE OR EXPLOSION HAZARD

Loading...

Loading...