# 45464K003 Page 13

After gas piping is complete, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means. Some soaps

used for leak detection are corrosive to certain

metals. Carefully rinse piping thoroughly after leak

detection has been completed.

Electrical Wiring

in the gas line, outside the unit, 5' above the floor, or in

accordance with any local codes. A test gauge connection

must be installed with a 1/8" NPT plugged tapping immedi-

ately upstream of the shutoff valve (see Figure 16).

The furnace must be isolated from the gas supply piping

system by closing the individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psig

(3.5 kPa) or 14" W.C. If the piping system is to be tested at

pressures in excess of 1/2 psig (3.5 kPa), the furnace and

its appliance main gas valve must be disconnected from

the gas supply piping system.

The gas valve supplied with this furnace is

rated at 1/2 psig maximum. Any higher pres-

sure may rupture the pressure regulator dia-

phragm and may cause overfiring of the burners

and improper burner operation. The overfiring

may result in the creation of carbon monoxide

which could cause asphyxiation.

WARNING

The furnace must be grounded and wired in accordance

with local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

and/or CSA C22.1 Electrical Code (latest edition) if an

external electrical source is utilized.

In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall

conform with the temperature limitation for Type T wire –

63°F (35°C) rise.

Connect a sufficiently sized wire with ground to the furnace’s

line voltage connections and ground lug. Refer to the

furnace rating plate for electrical characteristics to be used

in sizing field supply wiring and over-current protection.

The line voltage supply should be routed through a

readily accessible disconnect located within sight of the

furnace. A junction box on the furnace side panel is

provided for line voltage connections. Refer to the furnace

wiring diagram for specific connection information.

Proper polarity of the supply connections (“HOT”

and “NEUTRAL”) must be observed to ensure that

safety controls provide the protection intended.

A connection to the ground lug and actual earth ground

(typically a ground stake or buried steel pipe) must be

maintained for proper operation.

Thermostat

Install a room thermostat according to the instructions

furnished with it. Select a location on an inside wall that is

not subject to drafts, direct sunshine, or other heat

sources. The initial heat anticipator setting should be equal

to the total current draw of the control circuit.

Low voltage thermostat connections are to be made to the

blower control board as indicated on the wiring diagram.

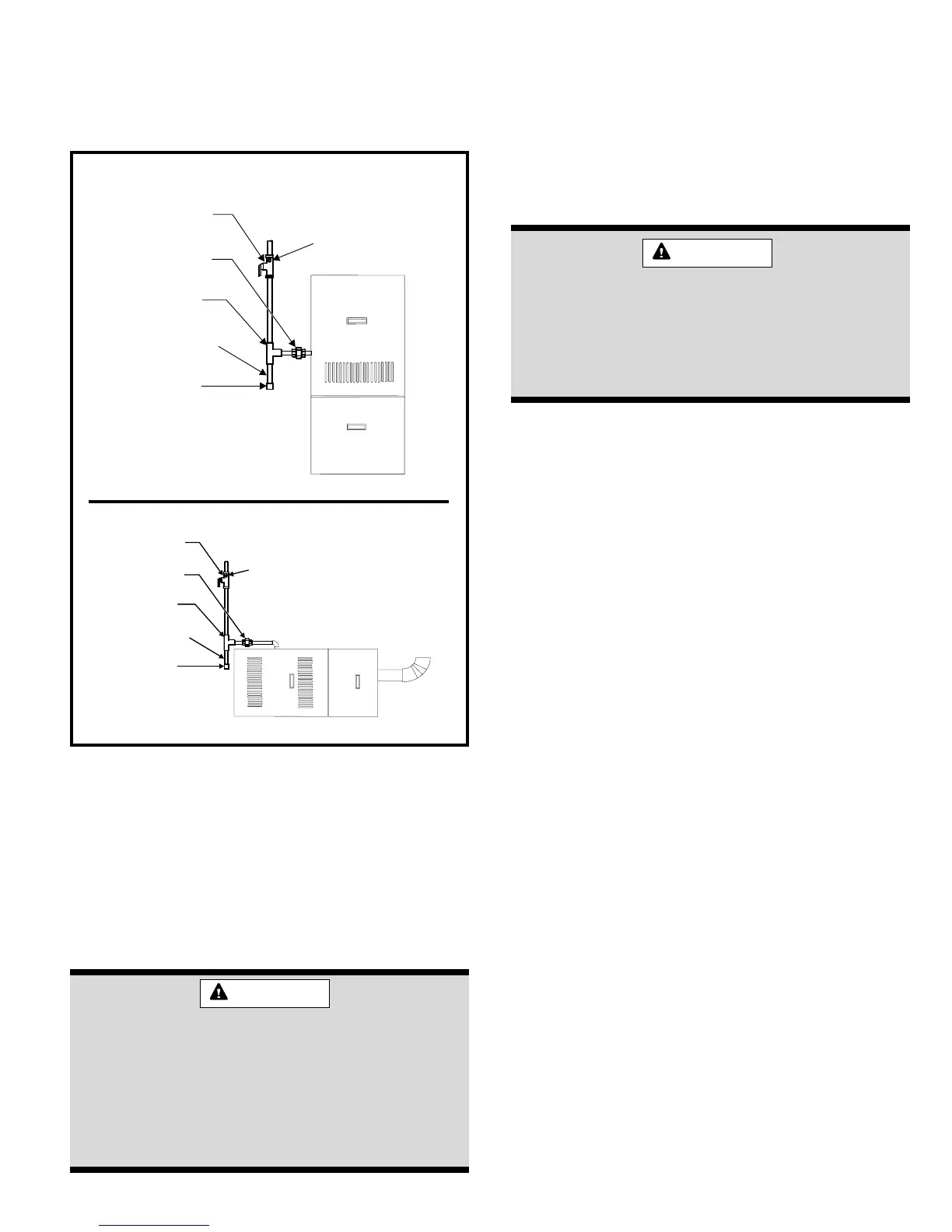

Manual

Gas Valve

Union

Te e

Drip Leg

Cap

1/8" NPT

Plugged

Tapping

Gas Connection

Horizontal

Installation

Figure 16

Manual

Gas Valve

Union

Te e

Drip Leg

Cap

1/8" NPT

Plugged

Tapping

Upflow/

Counterflow

Installation

Risk of electrical shock. Disconnect electrical

power at the circuit breaker or service panel

before making electrical connections. Failure

to disconnect power supplies can result in

property damage, personal injury, or death.

WARNING

Loading...

Loading...