# 45464K003Page 6

For 100K, 125K, and 150K BTUH input models,

the minimum vent connector diameter is 5". The

transition from 4" diameter flue outlet to 5"

diameter pipe must be made at the flue outlet.

IMPORTANT

• Printing inks, paint removers, varnishes, etc.

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

• Chlorinated laundry products

• Hydrochloric acid

Venting

This furnace has a fan-assisted combustion system

designed for vertical venting into a suitable chimney or

listed gas vent, and is classified as a Category I furnace

as shipped from the factory.

If this furnace is used to replace an existing furnace,

it is possible that the existing venting system is not

suitable for venting this furnace. Furthermore, the

existing venting system may have to be modified to

properly vent any other gas appliance, such as a water

heater, that remains connected to it. Carefully read the

Vertical Venting, Sidewall Venting, and Existing Vent

Systems sections that follow to determine proper venting

practices for the installation.

Installation shall be in accordance with Parts 7 and 11 of

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition) and/or Section 7 and Appendix B of the CSA

B149.1, Natural Gas and Propane Installation Codes

(latest edition); local building codes; vent manufacturer

instructions; and these instructions.

Vertical Venting

Category I furnaces must be vented vertically or nearly

vertically. Common venting and multistory venting are

permitted when done in accordance with applicable codes,

such as local and national codes.

The venting system should be designed in accordance with

the “FAN” columns in the venting tables in the latest editions

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the

CSA B149.1, Natural Gas and Propane Installation Codes.

1. Consult local building codes for installation require-

ments.

2. The vent connector should be as short as possible with

the least number of elbows and angles to do the job.

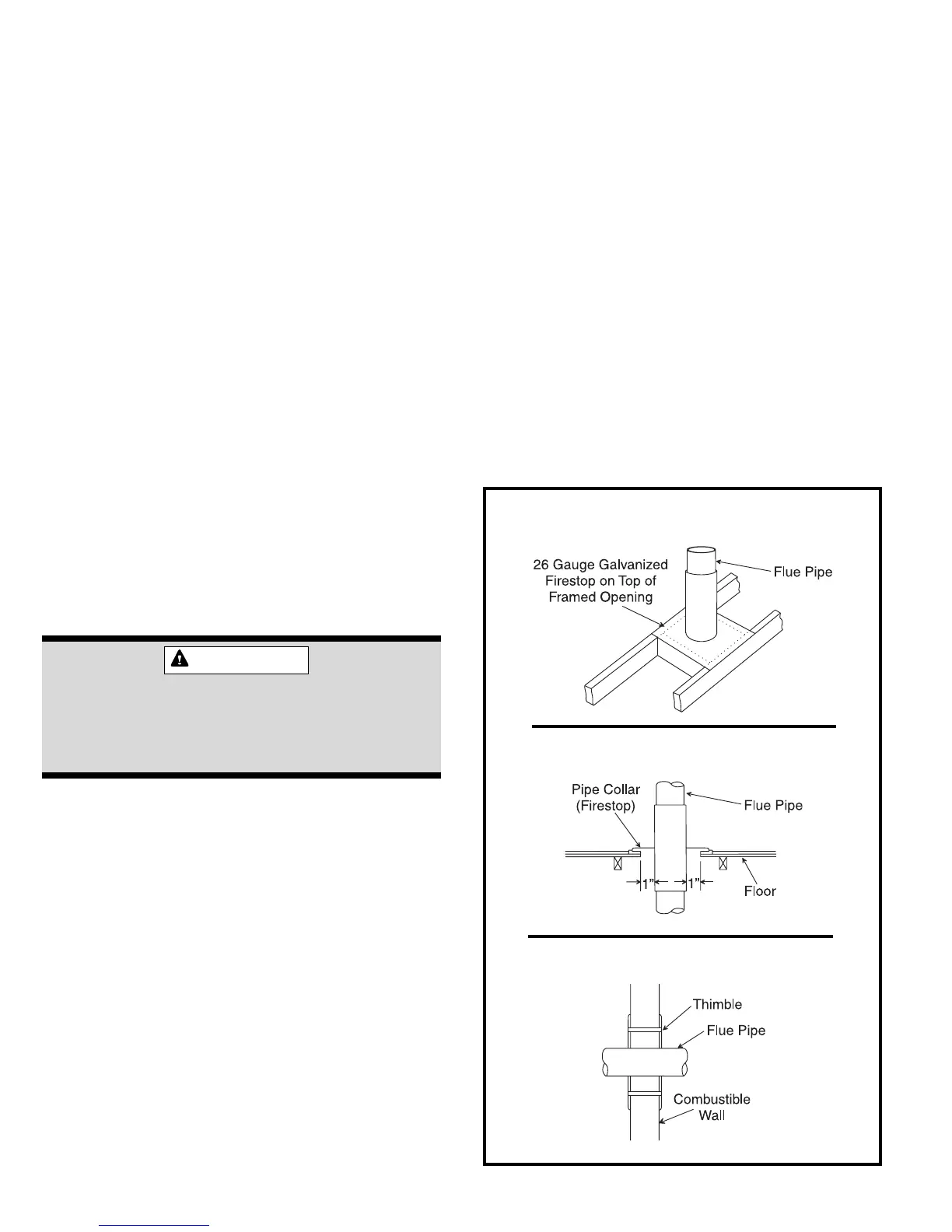

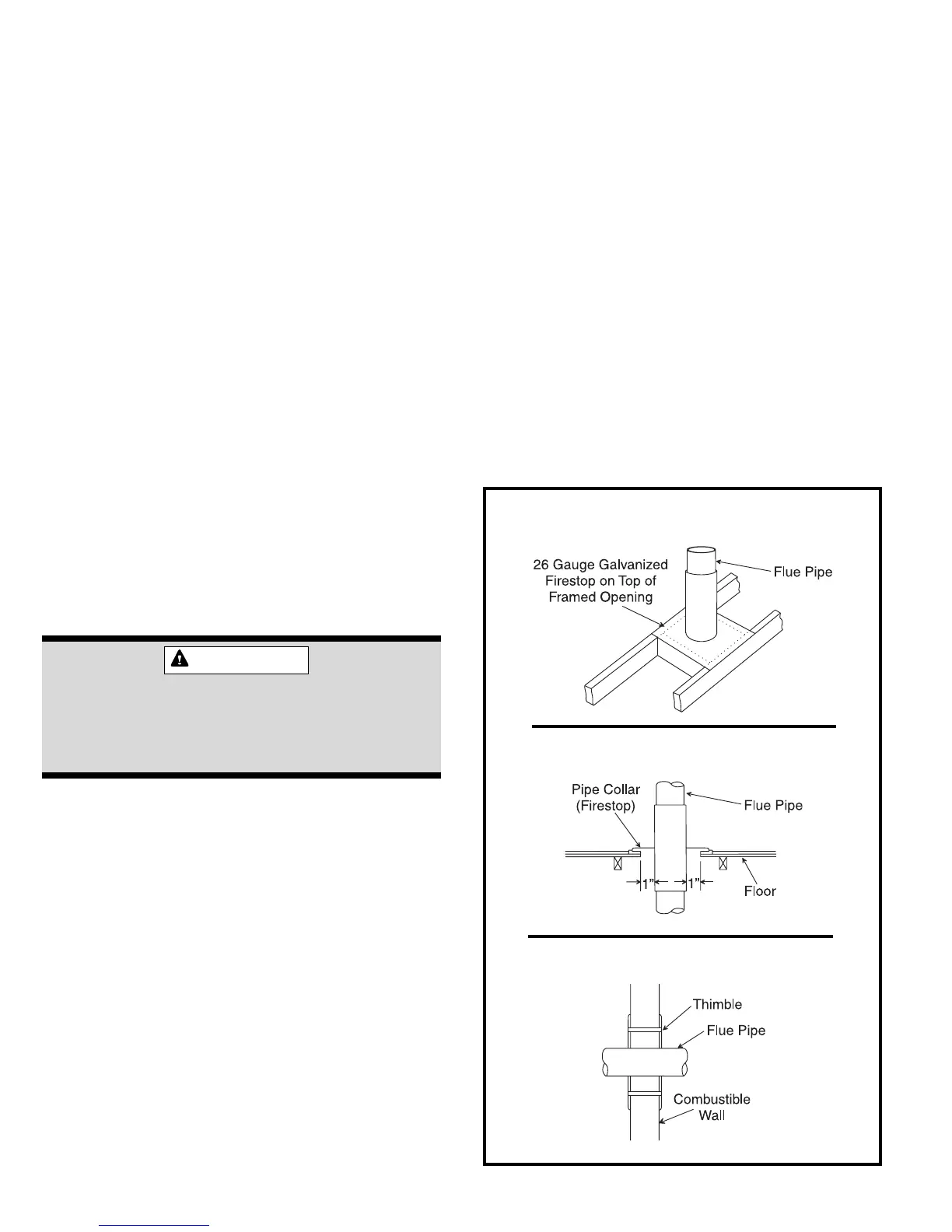

3. It is recommended a minimum of 26 gauge galvanized

flue pipe be used. Use of single-wall vent pipe for the

vent connector is permissible only in conditioned

space. Use Doublewall Type B vent pipe through

unconditioned space such as attics and crawl

spaces. The vent material used should be in accor-

dance with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 (latest edition) or the CSA B149.1, Natural

Gas and Propane Installation Codes and local codes.

Fan-assisted combustion system Category I furnaces

shall not be vented into single wall metal vents.

4. The vent connector must have an upward slope toward

the chimney on all horizontal runs of at least 1/4" per

foot of horizontal run and should be supported by a

sheet metal strap. The vent pipe connection must be

secured to the induced draft blower outlet. A single

screw is sufficient. On G1N80BR and CG80RB models,

a hole in the door hook will allow access to the blower

outlet without removing the door hook.

5. All vents passing through floors, ceilings, and walls

must be firestopped according to the requirements of

the National Fuel Gas Code (see Figure 7).

Figure 7

Vent Through Ceiling

Vent Through Floor

Vent Through Wall

Loading...

Loading...