# 45464K003 Page 7

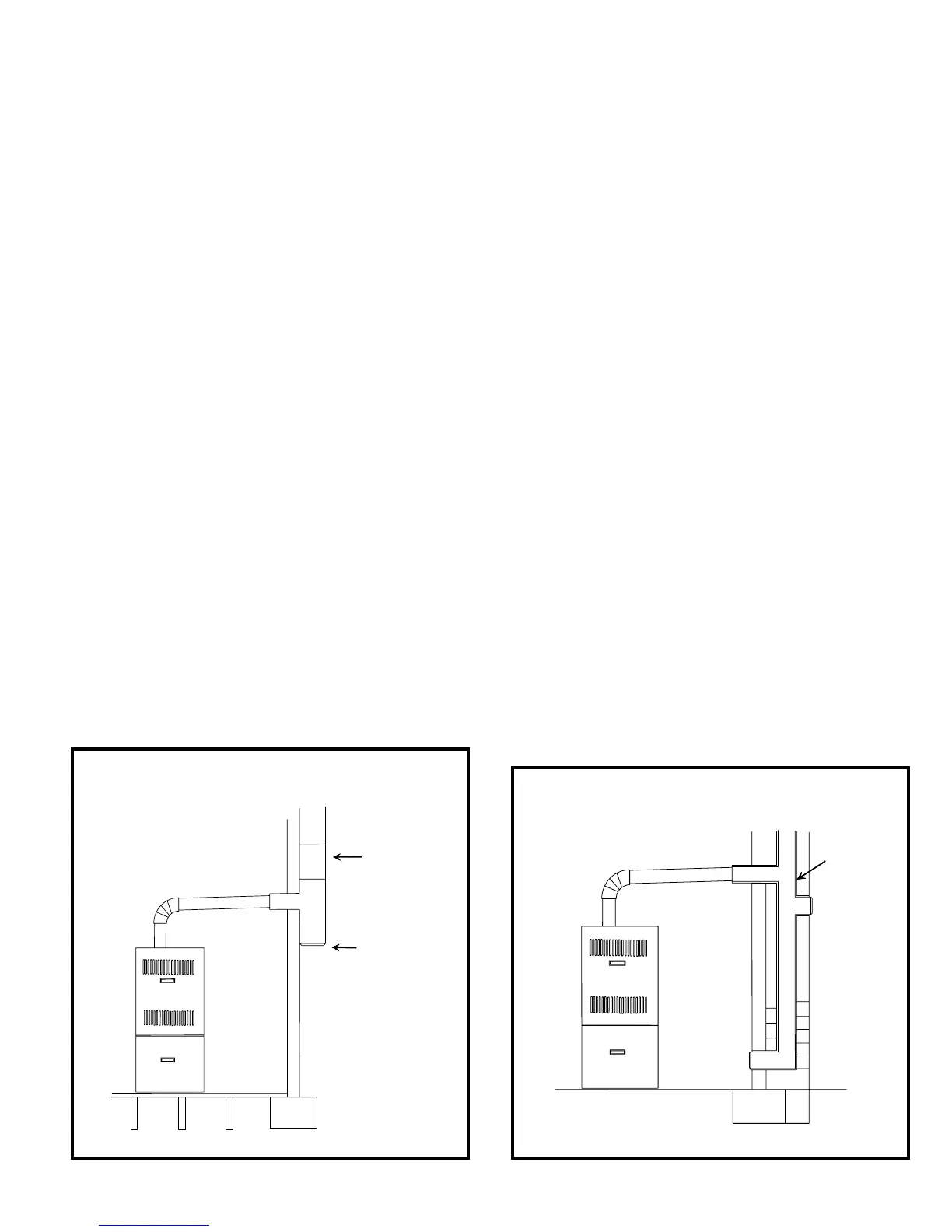

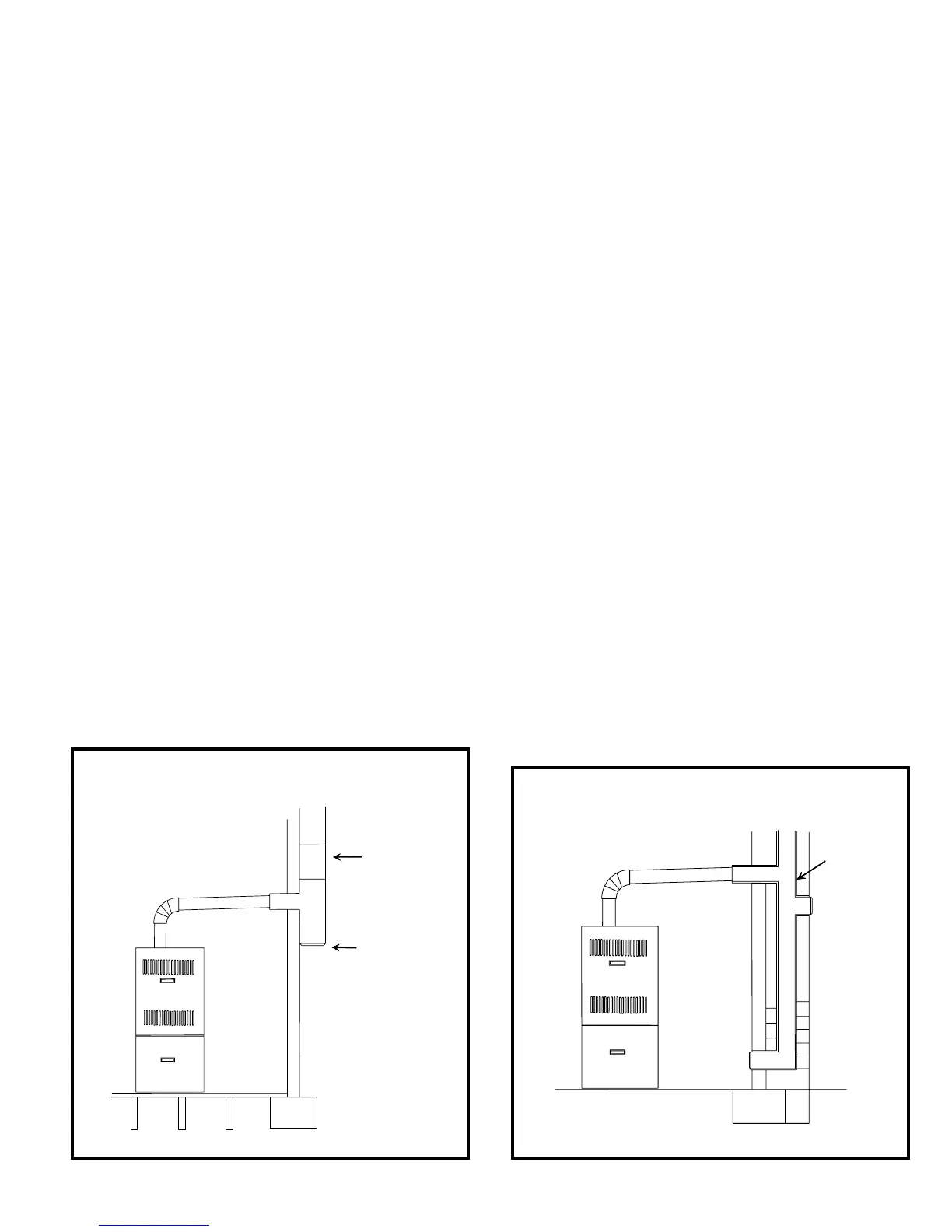

6. The furnace shall be connected to a factory-built

chimney or vent complying with a recognized stan-

dard, or a masonry or concrete chimney lined with a

lining material acceptable to the authority with jurisdic-

tion. Venting into an unlined chimney or a single

wall metal vent is prohibited in all cases. A lined

chimney may be used if a draft hood equipped

appliance, such as a water heater, is connected to

the same flue (see Figures 8 and 9).

7. Extend the vent connector into the chimney so that it

is flush with the inside of the flue liner. Seal the joint

between the pipe and the liner.

8. Masonry chimneys serving fireplaces cannot be used

for venting purposes unless the fireplace opening is

permanently sealed.

9. A vent connector serving this appliance must not be

connected into any portion of mechanical draft sys-

tems operating under positive pressure.

10. The vent pipe must not be connected to a chimney

flue serving a solid fuel appliance.

11. A manual damper, barometric draft regulator, or flue

restrictor must not be installed between the furnace

and the chimney.

12. Where local experience indicates that condensate may

be a problem, the vent shall be constructed to prevent

condensation from entering the combustion blower.

Provision shall be made to drain off the condensate

(see Figures 8 and 9).

13. All unused chimney openings should be closed.

14. All vent pipe run through unconditioned areas or

outside shall be constructed of factory-built chimney

sections (see Figure 8).

15. Multistory venting is allowed as permitted by the

National Fuel Gas Code or local codes.

16. Install all vents in accordance with the vent

manufacturer’s instructions. For unlisted material,

install in accordance with the National Fuel Gas Code.

17. Vent terminals must be installed in accordance with

the vent terminals listing or in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition) or the CSA B149.1, Natural Gas and Propane

Installation Codes, and local codes.

Sidewall Venting

This furnace can be sidewall (horizontally) vented with a

listed sidewall venter, such as Field Controls Model SWG-

4HD with CK-43 Control Kit, or Tjernlund Model GPAK-JT.

Category I venting classification is maintained when vented

in this manner. The furnace, power venter, and control kit

(where applicable) must be installed in accordance with their

installation instructions and all applicable codes.

The following limitations also apply to the two previously

mentioned venters.

Vent pipe diameter: 4"

Minimum vent pipe length: 4'

Maximum vent pipe length: 25'*

Maximum number of 90° elbows: 4

* When fewer than four elbows are used, maximum vent

pipe length can be increased by 5' per unused elbow.

Liner

Masonry

Chimney

Cleanout

Masonry Chimney Venting

Figure 9

Factory-Built

Chimney

Cleanout

Factory-Built Chimney Venting

Figure 8

Loading...

Loading...