Page 11

WARNING

Improper installation of the furnace can result in perĆ

sonal injury or death. Combustion and flue products

must never be allowed to enter the return air system

or the living space. Use screws and joint tape to seal

the return air system to the furnace.

In platform installations with bottom return air, the

furnace should be sealed airtight to the return air pleĆ

num. A door must never be used as a portion of the

return air duct system. The base must provide a

stable support and an airtight seal to the furnace. AlĆ

low absolutely no sagging, cracks, gaps, etc.

The return and supply air duct systems must never

be connected to or from other heating devices such

as a fireplace or stove, etc. Fire, explosion, carbon

monoxide poisoning, personal injury and/or properĆ

ty damage could result.

Duct System

Use industryĆapproved standards to size and install the

supply and return air duct system. This will result in a quiet

and lowĆstatic system that has uniform air distribution.

Supply Air Plenum

Furnaces installed without a cooling coil require the installaĆ

tion of a removable access panel in the supply air duct. The

access panel should be large enough to permit inspection (eiĆ

ther by smoke or reflected light) of the heat exchanger for

leaks after installation . The furnace access panel must alĆ

ways be in place when the furnace is operating and it must

not allow leaks into the supply air duct system.

Return Air Plenum

Return air must not be drawn from a room where this

furnace, or any other gas appliance (ie., a water heatĆ

er), is installed. When return air is drawn from a room,

a negative pressure is created in the room. If a gas apĆ

pliance is operating in a room with negative pressure, the

flue products can be pulled back down the vent pipe and

into the room. This reverse flow of the flue gas may result

in incomplete combustion and the formation of carbon

monoxide gas. This toxic gas might then be distributed

throughout the house by the furnace duct system.

In upflow applications, return air can be brought in through

the bottom or either side of the furnace. If a furnace with

bottom return air is installed on a platform, make an airtight

seal between the bottom of the furnace and the platform to

ensure proper and safe operation. Use fiberglass sealing

strips between the plenum and the furnace cabinet to enĆ

sure a tight seal. If a filter is installed, size the return air duct

to fit the filter frame.

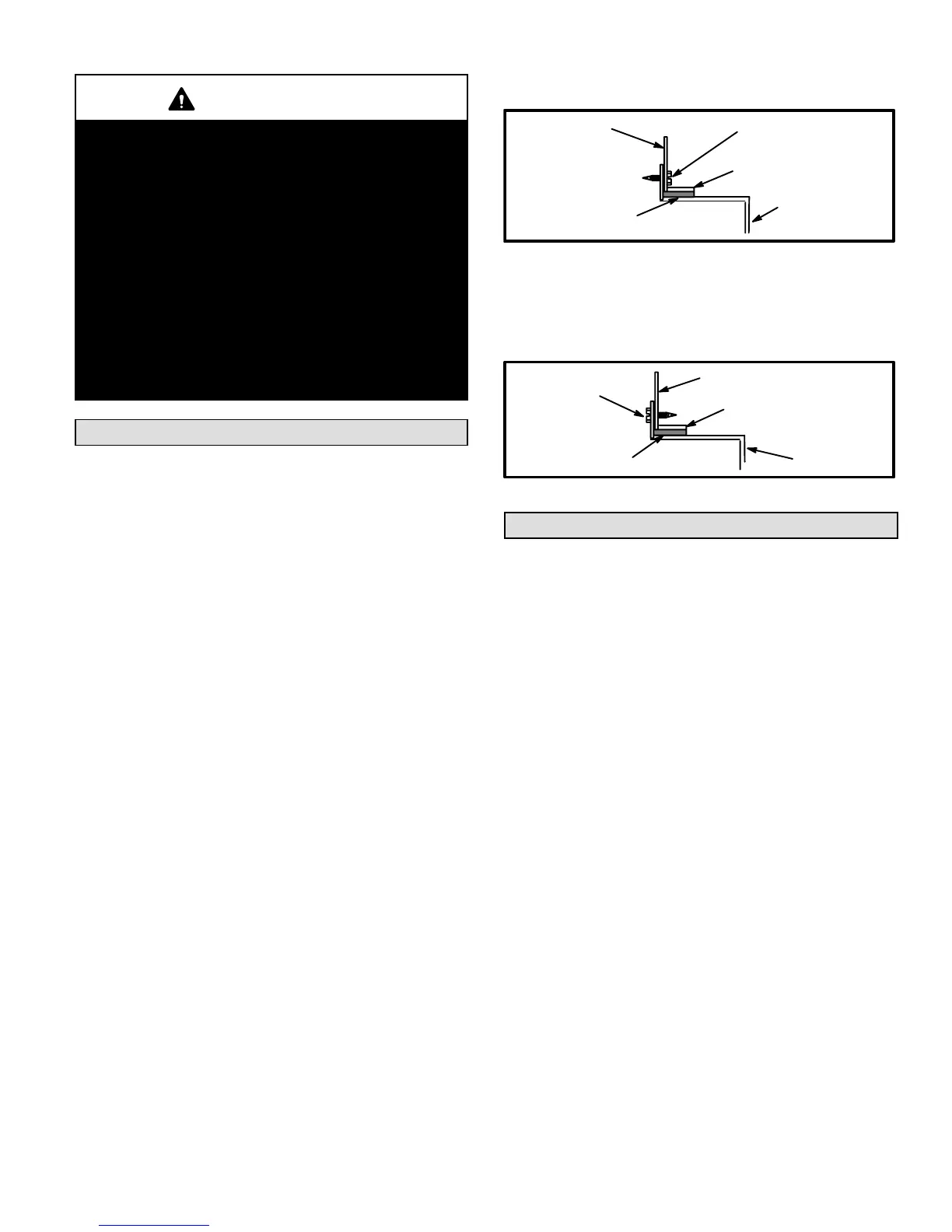

In downflow applications, use the following steps when instalĆ

ling return air plenum:

1 - Flange bottom edge of plenum with a hemmed edge.

See figure 12.

2 - Use fiberglass sealing strips between plenum and the

unit cabinet to ensure a tight seal.

3 - In all cases, secure the plenum to the top flanges of the

furnace using sheet metal screws. See figure 12.

SECURE

HEMMED EDGE

PLENUM

CABINET

SIDE PANEL

FIBERGLASS

SEALING STRIP

FIGURE 12

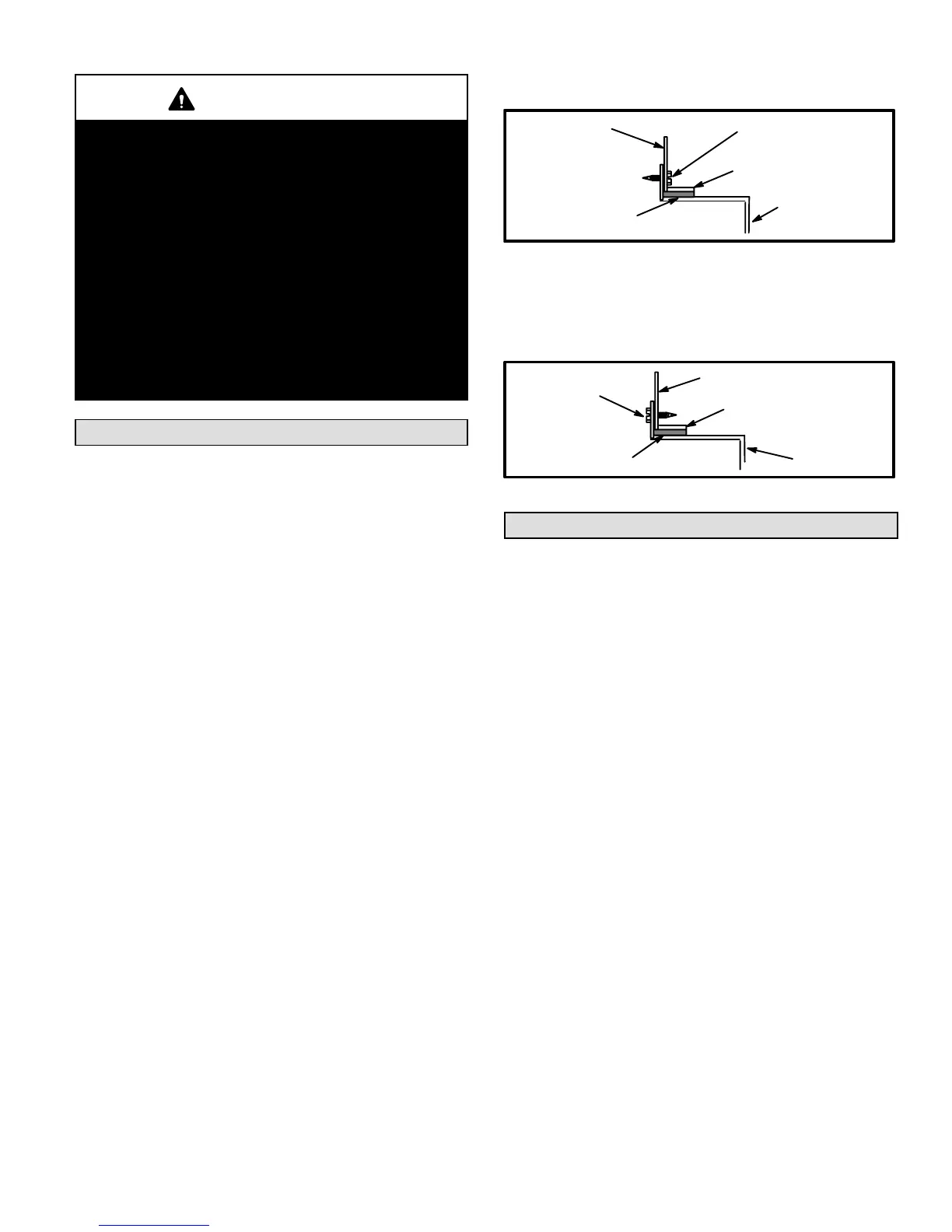

4 - In closet installations, it may be necessary to install

sheet metal screws from the inside. If this is the case,

make plenum with a removable front to install screws

as shown in figure 13.

SECURE FROM

INSIDE

HEMMED EDGE

FIBERGLASS

SEALING STRIP

CABINET

SIDE PANEL

PLENUM

FIGURE 13

Venting

A vent adapter is supplied with the furnace. It must be

installed between the induced draft blower flue outlet and

the vent connector using one or two corrosion-resistant

sheet metal screws. Modification of, or failure to install,

the adapter will cause unsafe unit operation and will

void A.G.A. and C.G.A. unit certification. The vent conĆ

nector does not require insulation.

The G24M series units are classified as fan-assisted CateĆ

gory I furnaces when vertically vented according to the latest

edition of ANSI Z21.47 Central Furnace Standard in the

USA and the current standards of CAN/CGA B149.1 and

B149.2 of the Natural Gas and Propane Installation Code in

Canada. A fan-assisted Category I furnace is an appliance

equipped with an integral mechanical means to either draw

or force products of combustion through the combustion

chamber and/or heat exchanger.

NOTE - Use these instructions as a guide. They do not suĆ

persede local codes.

The vent sizing tables in this manual were extracted from

the National Fuel Gas Code (NFPA 54 / ANSI Z223.1) and

are provided as a guide for proper vent installation. Proper

application, termination, construction and location of vents

must conform to local codes having jurisdiction. In the abĆ

sence of local codes, the NFGC serves as the defining docĆ

ument.

Refer to the tables and the venting information contained in

these instructions to properly size and install the venting

system.

Install first vent connector elbow a minimum of 6 in.

(152mm) from furnace vent outlet.

Loading...

Loading...