Page 18

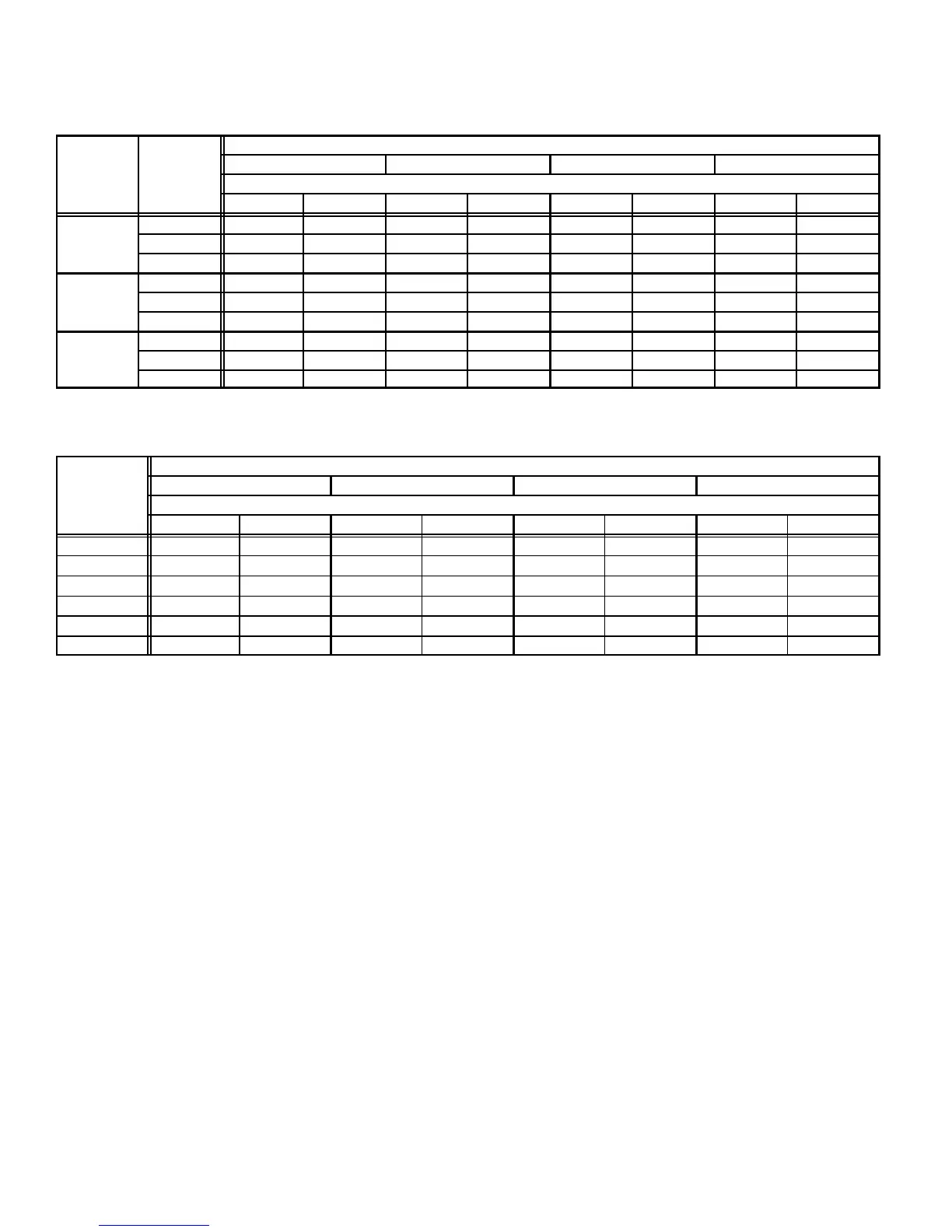

TABLE 8

CAPACITY OF TYPE B DOUBLE-WALL VENT WITH SINGLE-WALL METAL CONNECTORS

SERVING TWO OR MORE CATEGORY I APPLIANCES - VENT CONNECTOR CAPACITY

Vent and Connector Diameter - D (inches)

en

Hei

ht

onnec

or

Rise

3 Inch 4 Inch 5 Inch 6 Inch

H

R

Appliance Input Rating in Thousands of Btu Per Hour

(feet) (feet)

MIN MAX MIN MAX MIN MAX MIN MAX

1 NR NR NR NR NR NR NR NR

6

2 NR NR NR NR NR NR 168 182

3 NR NR NR NR 121 131 174 198

1 NR NR 79 87 116 138 177 214

15

2 NR NR 83 94 121 150 185 230

3 NR NR 87 100 127 160 193 243

1 47 60 77 110 113 175 169 278

30

2 50 62 81 115 117 185 177 290

3 54 64 85 119 122 193 185 300

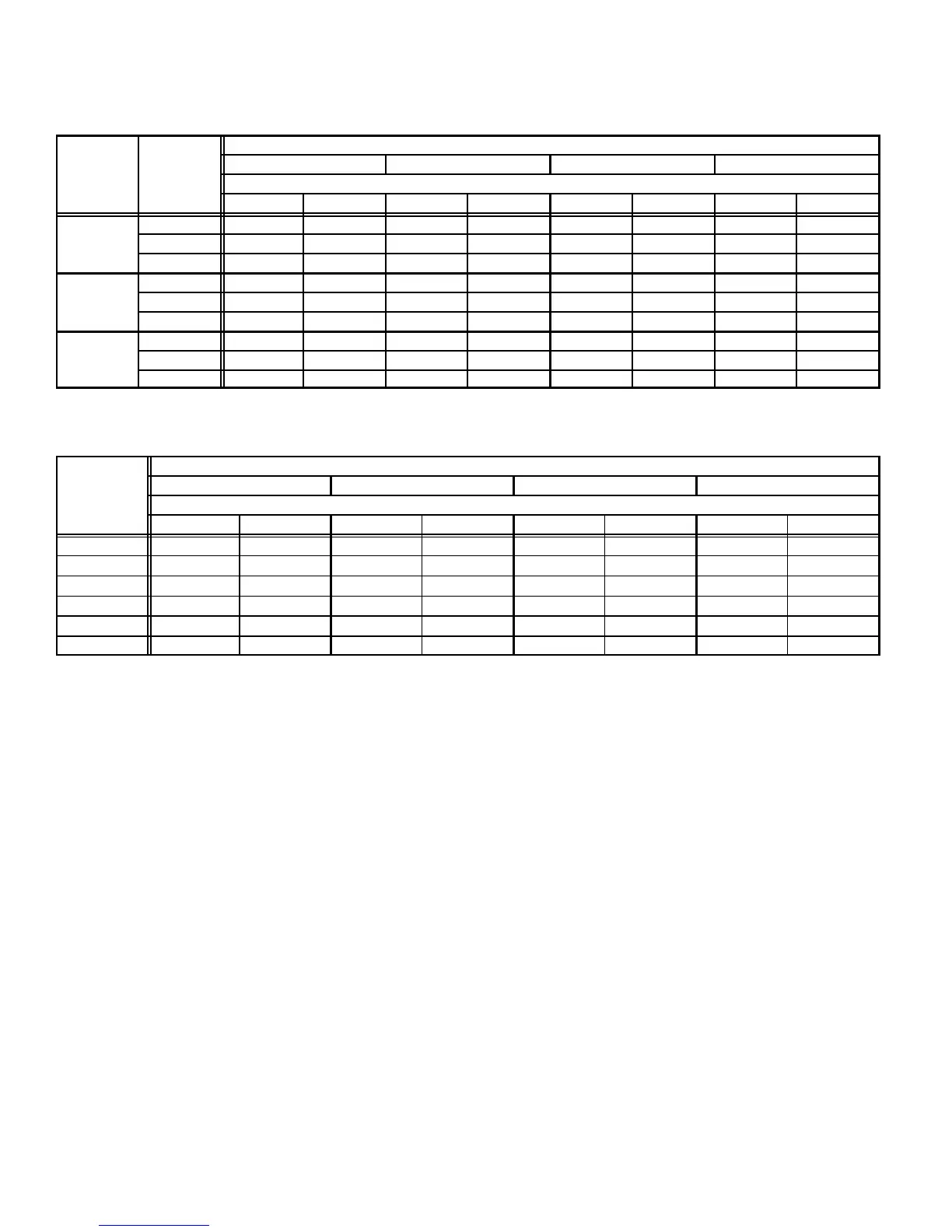

TABLE 9

CAPACITY OF TYPE B DOUBLE-WALL VENTS WITH SINGLE-WALL METAL CONNECTORS

SERVING TWO OR MORE CATEGORY I APPLIANCES - COMMON VENT CAPACITY

Common Vent Diameter - D (inches)

en

Hei

ht

4 Inch 5 Inch 6 Inch 7 Inch

H

Appliance Input Rating in Thousands of Btu Per Hour

(feet)

FAN + FAN FAN + NAT FAN + FAN FAN + NAT FAN + FAN FAN + NAT FAN + FAN FAN + NAT

6 89 78 136 113 200 158 304 244

8 98 87 151 126 218 173 331 269

10 106 94 163 137 237 189 357 292

15 121 108 189 159 275 221 416 343

20 131 118 208 177 305 247 463 383

30 145 132 236 202 350 286 533 446

Removal of Unit from Common Vent

In the event that an existing furnace is removed from a

venting system commonly run with separate gas apĆ

pliances, the venting system is likely to be too large to

properly vent the remaining attached appliances. The folĆ

lowing test should be conducted while each appliance in

operation and the other appliances not in operation reĆ

main connected to the common venting system. If the

venting system has been installed improperly, the system

must be corrected as indicated in the general venting reĆ

quirements section.

1 - Seal any unused openings in the common venting

system.

2 - Visually inspect the venting system for proper size and

horizontal pitch. Determine there is no blockage or reĆ

striction, leakage, corrosion, or other deficiencies which

could cause an unsafe condition.

3 - To the extent that it is practical, close all building doors

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other spaces

of the building. Turn on clothes dryers and any apĆ

pliances not connected to the common venting sysĆ

tem. Turn on any exhaust fans, such as range hoods

and bathroom exhausts, so they will operate at maxiĆ

mum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

4 - Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so apĆ

pliance will operate continuously.

5 - Test for spillage of flue gases at the draft hood relief

opening after 5 minutes of main burner operation. Use

the flame of a match or candle, or smoke from a cigaĆ

rette, cigar or pipe.

6 - After determining that each appliance remaining conĆ

nected to the common venting system properly vents

when tested as indicated in step 3, return doors, winĆ

dows, exhaust fans, fireplace dampers and any other

gasĆburning appliance to their previous condition of

use.

7 - If improper venting is observed during any of the

above tests, the common venting system must be corĆ

rected. The common venting system should be reĆ

sized to approach the minimum size as determined by

using the appropriate tables in appendix G in the curĆ

rent standards of the National Fuel Gas Code ANSI

Z223.1 in the USA, and the appropriate Category 1

Natural Gas and Propane appliances venting sizing

tables in the current standards of the CAN/CGA

B149.1 and B149.2 in the Natural Gas and Propane

Installation Code in Canada.

Loading...

Loading...