Page 19

Gas Piping

Gas Supply

1 - This unit is shipped standard for left or right side instalĆ

lation of gas piping (or top entry in horizontal applicaĆ

tions). Connect the gas supply to the piping assembly.

2 - When connecting the gas supply, factors such as

length of run, number of fittings and furnace rating

must be considered to avoid excessive pressure drop.

Table 10 lists recommended pipe sizes for typical apĆ

plications.

3 - The gas piping must not run in or through air ducts,

clothes chutes, gas vents or chimneys, dumb waiters

or elevator shafts.

4 - The piping should be sloped 1/4 inch (6.4 mm) per 15 feet

(4.57 m) upward toward the meter from the furnace. The

piping must be supported at proper intervals [every 8 to

10 feet (2.44 to 3.01 m) using suitable hangers or straps.

A drip leg should be installed in vertical pipe runs to the

unit.

5 - In some localities, codes may require installation of a

manual main shutĆoff valve and union (furnished by

the installer) external to the unit. Union must be of the

ground joint type.

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified petroĆ

leum gases.

NOTE - Install a 1/8 inch NPT plugged tap in the field piping

upstream of the gas supply connection to the unit. The tap

must be accessible for test gauge connection. See figure 16.

NOTE - In case emergency shutoff is required, shut off main

manual gas valve and disconnect main power to unit. These

devices should be properly labeled by the installer.

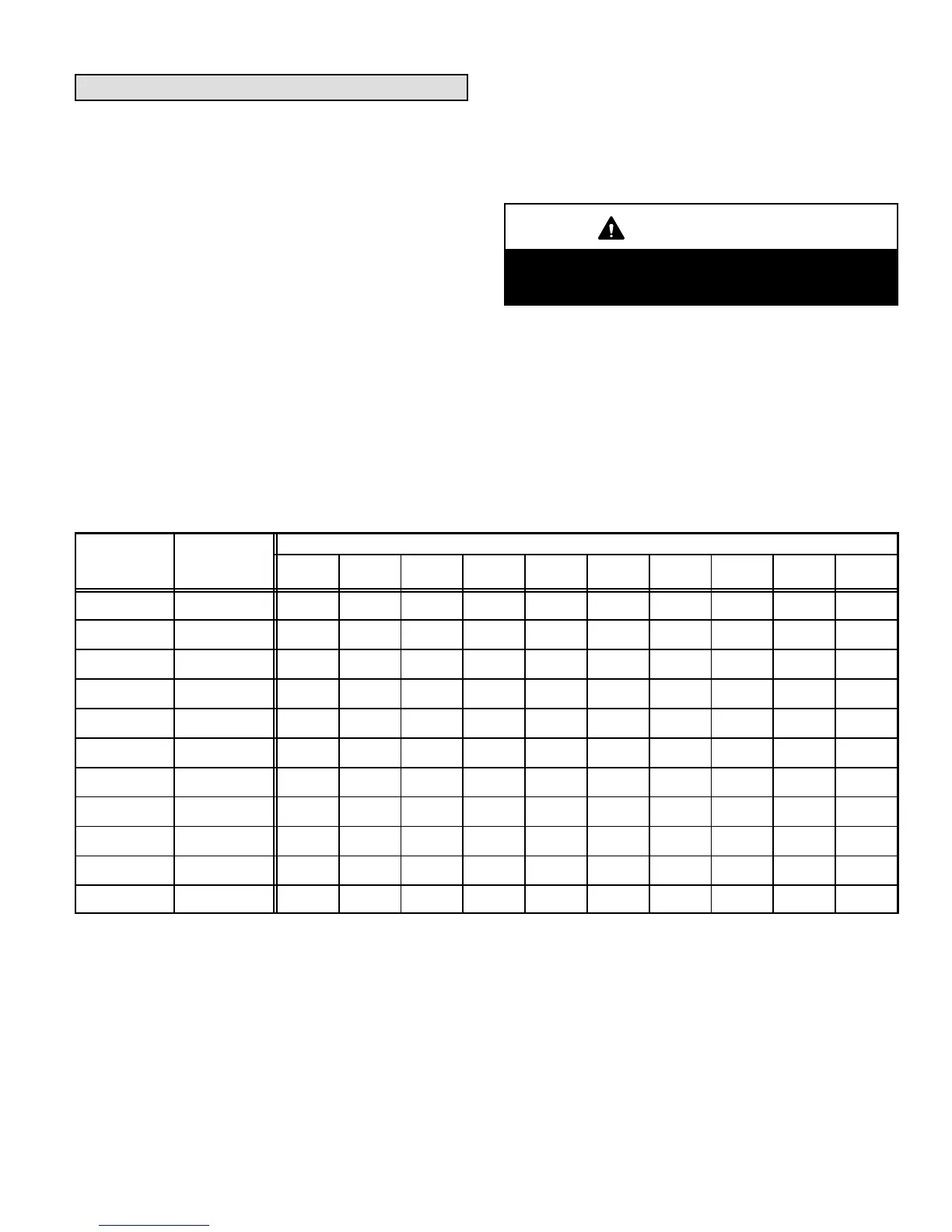

TABLE 10

GAS PIPE CAPACITY - FT

3

/HR (M

3

/HR)

Nominal Internal

Length of Pipe - feet (m)

Iron Pipe Size

inches (mm)

Diameter

inches (mm)

10

(3.048)

20

(6.096)

30

(9.144)

40

(12.192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30.480)

1/4

(6.35)

.364

(9.246)

43

(1.13)

29

(.82)

24

(.68)

20

(.57)

18

(.51)

16

(.45)

15

(.42)

14

(.40)

13

(.37)

12

(.34)

3/8

(9.53)

.493

(12.522)

95

(2.69)

65

(1.84)

52

(1.47)

45

(1.27)

40

(1.13)

36

(1.02)

33

(.73)

31

(.88)

29

(.82)

27

(.76)

1/2

(12.7)

.622

(17.799)

175

(4.96)

120

(3.40)

97

(2.75)

82

(2.32)

73

(2.07)

66

(1.87)

61

(1.73)

57

(1.61)

53

(1.50)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

250

(7.08)

200

(5.66)

170

(4.81)

151

(4.28)

138

(3.91)

125

(3.54)

118

(3.34)

110

(3.11)

103

(2.92)

1

(25.4)

1.049

(26.645)

680

(919.25)

465

(13.17)

375

(10.62)

320

(9.06)

285

(8.07)

260

(7.36)

240

(6.80)

220

(6.23)

205

(5.80)

195

(5.52)

1-1/4

(31.75)

1.380

(35.052)

1400

(39.64)

950

(26.90)

770

(21.80)

660

(18.69)

580

(16.42)

530

(15.01)

490

(13.87)

460

(13.03)

430

(12.18)

400

(11.33)

1-1/2

(38.1)

1.610

(40.894)

2100

(59.46)

460

(41.34)

1180

(33.41)

990

(28.03)

900

(25.48)

810

(22.94)

750

(21.24)

690

(19.54)

650

(18.41)

620

(17.56)

2

(50.8)

2.067

(52.502)

3950

(111.85)

2750

(77.87)

2200

(62.30)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1150

(32.56)

2-1/2

(63.5)

2.469

(67.713)

6300

(178.39)

4350

(123.17)

3520

(99.67)

3000

(84.95

2650

(75.04)

2400

(67.96)

2250

(63.71)

2050

(58.05)

1950

(55.22)

1850

(52.38)

3

(76.2)

3.068

(77.927)

11000

(311.48)

7700

(218.03)

6250

(176.98)

5300

(150.07)

4750

(134.50)

4300

(121.76)

3900

(110.43)

3700

(104.77)

3450

(97.69)

3250

(92.03)

4

(101.6)

4.026

(102.260)

23000

(651.27)

15800

(447.39)

12800

(362.44)

10900

(308.64)

9700

(274.67)

8800

(249.18)

8100

(229.36)

7500

(212.37)

7200

(203.88)

6700

(189.72)

NOTE-Capacity given in cubic feet (m

3

) of gas per hour and based on 0.60 specific gravity gas.

Loading...

Loading...