Page 24

Turning Off Gas To Unit

1 - Set the thermostat to lowest setting.

2 - Turn off all electrical power to the unit if service is to be

performed.

3 - Remove the access panel.

4 - Turn knob on White Rodgers gas valve 180° either way

to OFF; turn knob on Honeywell valve clockwise

to

OFF. Do not force.

5 - Replace the access panel.

Heating Sequence Of Operation

1 - When the thermostat calls for heat, the combustion air

blower starts after a 5 second delay.

2 - the combustion air pressure switch proves blower opĆ

eration, then energizes the ignition control. The switch

is factoryĆset and requires no adjustment.

3 - After 15-second prepurge cycle, the spark ignitor enĆ

ergizes and the gas valve opens.

4 - The spark ignites the gas, ignition sensor proves the

flame and the combustion process continues.

5 - If flame is not detected after first ignition trial, igniĆ

tion control will repeat steps 3 and 4 four more times

before locking out. To reĆestablish ignition attempts

after lockout, proceed as follows:

a - Turn OFF the power to the furnace.

b - Move the thermostat control from the HEAT" to

the OFF" position.

c - Turn ON the power to the furnace.

d - Move the thermostat control from the OFF" to

HEAT" position.

Gas Pressure Adjustment

Gas Flow

To check for proper gas flow to the combustion chamber,

determine the Btu (kW) input from the unit rating plate. DiĆ

vide this input rating by the Btu (kW) per cubic foot (cubic

meter) of available gas. The result is the required number

of cubic feet (cubic meter) per hour. Determine the flow of

gas through the gas meter for two minutes and multiply by

30 to get the hourly flow of gas.

Gas Pressure

1 - Check the gas line pressure with the unit firing at maxiĆ

mum rate. A minimum of 4.5 in. w.c. for natural gas or

11.0 in. w.c. for LP/propane gas should be maintained.

2 - After the line pressure has been checked and adĆ

justed, check the regulator pressure. See figures 21

and 22 for gas pressure adjustment screw location. For

manifold pressure settings, refer to the rating plate on

the unit. A natural gas to LP/propane gas changeover

kit is required to convert the unit.

High Altitude Information

Refer to the rating plate on the unit for high altitude information.

Other Unit Adjustments

Primary And Secondary Limits

The primary limit is located on the heating compartment vesĆ

tibule panel. Two secondary limits are located in the blower

compartment, behind the blower. These limits are factoryĆset

and require no adjustment.

Flame Rollout Switches (Two)

These manually reset switches are located just above the

burner box. If tripped, a check for adequate combustion air

should be made before resetting.

Combustion Air Pressure Switch

The combustion air pressure switch is located on the heatĆ

ing compartment vestibule panel. This switch checks for

proper combustion air blower operation before allowing

ignition trial. The switch is factory set and requires no adĆ

justment.

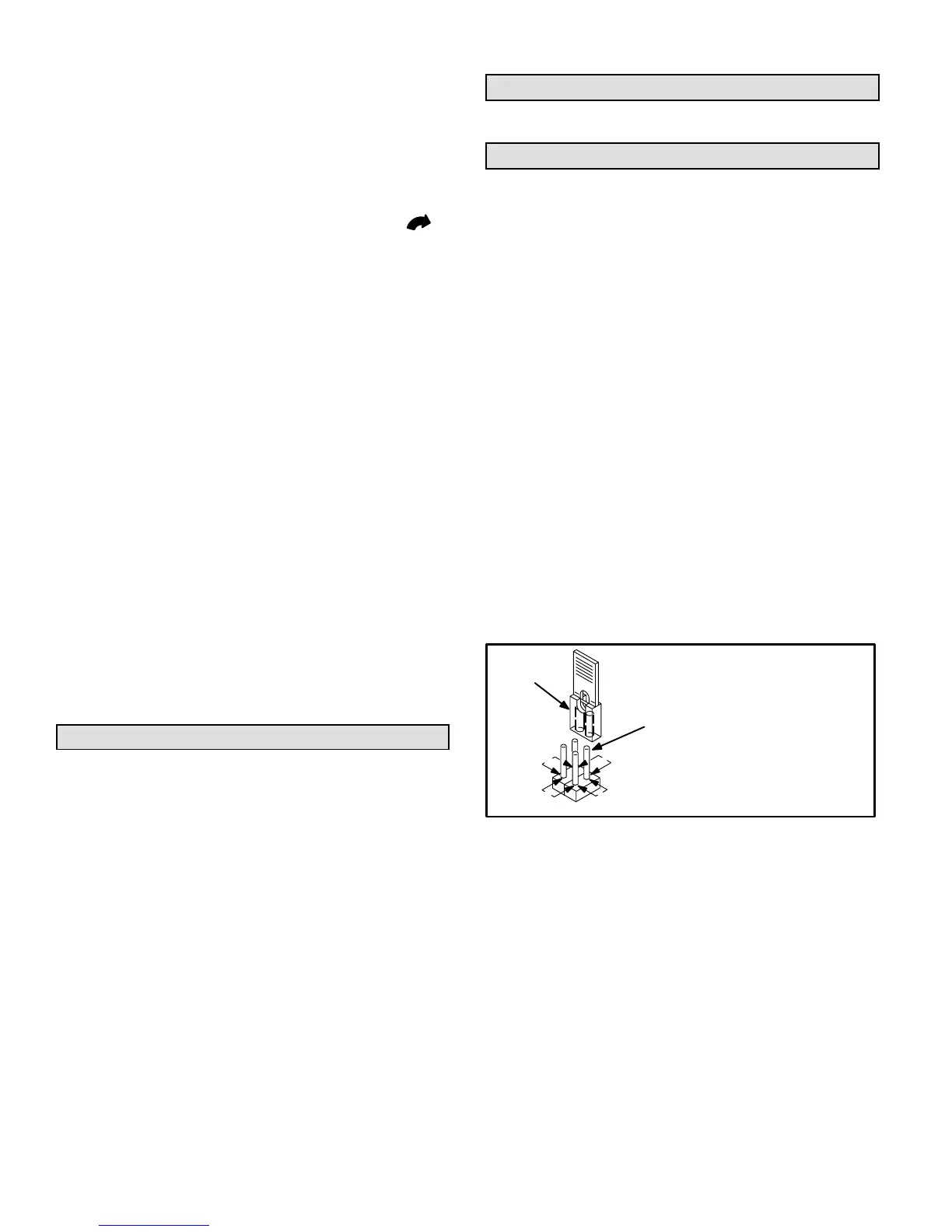

Fan Timer Control

The fan control is part of the integrated control board loĆ

cated on the blower access panel. The fanĆon delay time of

45 seconds is not adjustable. The fanĆoff delay time is facĆ

tory set at 120 seconds and can be adjusted by moving the

jumper on the integrated control board. See figure 23 for

settings.

120

180

90 60

To adjust fan-off delay, remove the

jumper and select the appropriate pin

combination to achieve the desired

delay.

TIMING

JUMPER

TIMING PINS

(seconds)

Fan-off Delay Adjustment

FIGURE 23

Temperature Rise

Check the temperature rise and, if necessary, adjust the

blower speed to maintain the temperature rise within the

range shown on the unit rating plate.

Thermostat Heat Anticipation

Set the thermostat heat anticipation :

0.50 amps White Rodgers gas valves

0.70 amps Honeywell gas valves

Electrical

1 - Check all wiring for loose connections.

2 - Check for the correct voltage at the furnace (furnace

operating).

3 - Check amp-draw on the blower motor.

Motor Nameplate__________Actual__________

Loading...

Loading...