Page 26

Service

WARNING

Disconnect power before servicing unit.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and danĆ

gerous operation. Verify proper operation after serĆ

vicing.

At the beginning of each heating season, the system

should be checked as follows:

Blowers

Check blower wheels for any debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

Filters

All G24M filters are installed external to the unit. Filters

should be inspected monthly.Clean or replace the filters

when necessary to assure proper furnace operation. See

table 11 for filter sizes. Replacement filters for

G24M-45/60/75 units must have a minimum velocity rating

of 400 FPM. Replacement filters for G24M-100/120/140

units require a minimum velocity rating of 625 FPM.

TABLE 11

Model Number Filter Size - inches (mm)

G24M-45/60/75 16 X 20 X 1 (406 X 508 X 25)

G24M-100/120/140 20 X 20 X 1 (508 X 508 X 25)

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can

be drawn into living space resulting in personal injuĆ

ry or death.

Flue And Chimney

Check the flue pipe, chimney and all connections for tightĆ

ness and to make sure there is no blockage.

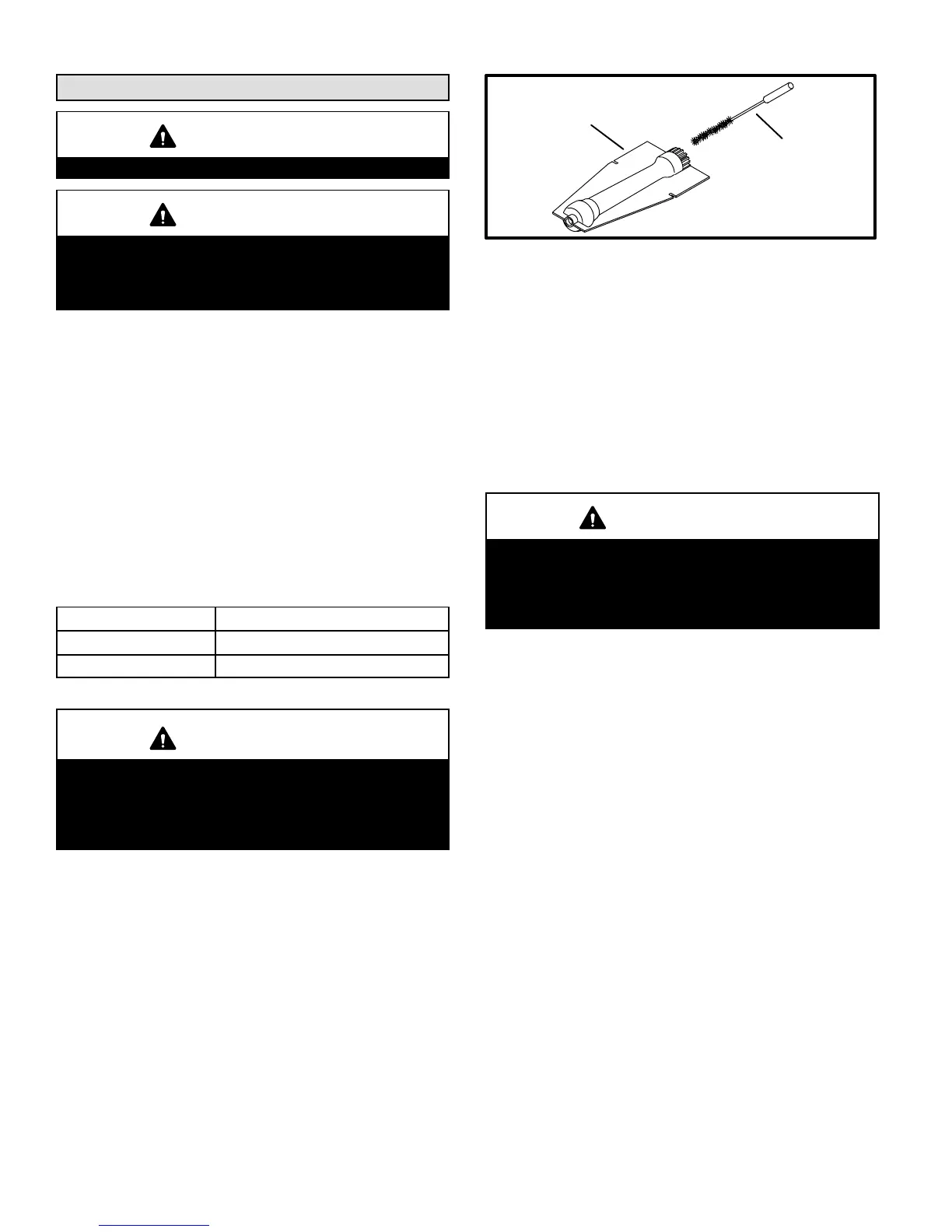

Burners

Inspect the burners and burner flame at the beginning of

each heating season. If necessary, clean the burners as

indicated below:

1 - Turn off electrical and gas supply to unit.

2 - Disconnect gas supply piping and remove gas manĆ

ifold.

3 - Disconnect ignitor and flame sensor leads.

4 - Remove burner tray and burners.

5 - Clean the inside of each burner with a bottle brush as

shown figure 26.

Cleaning Burners

BOTTLE

BRUSH

BURNER

FIGURE 26

6 - Replace burners and burner tray, making sure burners

are properly seated in slots on tray and orifice in manĆ

ifold.

7 - Check electrode gap using appropriately sized twist

drills or feeler gauges. Gap should be between 0.110

and 0.140 inches (2.79 to 3.56mm).

8 - Reinstall burner box and gas supply piping. ReconĆ

nect ignitor and flame sensor leads.

9 - Carefully check all piping connections (factory and field)

for gas leaks. Use a leak detecting solution or other preĆ

ferred means.

IMPORTANT

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly afĆ

ter leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

10 - Restore electrical power and gas supply. Follow lightĆ

ing instructions on front of unit. Check burner flame

and adjust if necessary.

Heat Exchanger

Periodically inspect the heat exchanger tubes and the flue

box for corrosion. If necessary, clean as indicated below:

1 - Turn off the electrical power and gas supply to the furĆ

nace.

2 - Disconnect the wiring to the combustion air fan.

3 - Remove the screws securing the flue box to the furĆ

nace. Clean the flue box with a wire brush (brassĆ

bristle brush recommended).

4 - Disconnect the gas supply piping and the ignitor and

sensor wires. Remove the burner assembly from the

furnace.

5 - Pull a largeĆbore wire brush (brassĆbristle brush recomĆ

mended) through each heat exchanger tube to clean.

6 - Reinstall the flue box using a new gasket.

7 - Reconnect the combustion air fan wiring.

8 - Reinstall the burner box, ignitor and sensor wires and

the gas supply piping.

9 - Carefully check all piping connections (factory and field)

for gas leaks. Use a leak detecting solution or other preĆ

ferred means.

Loading...

Loading...