Page 46

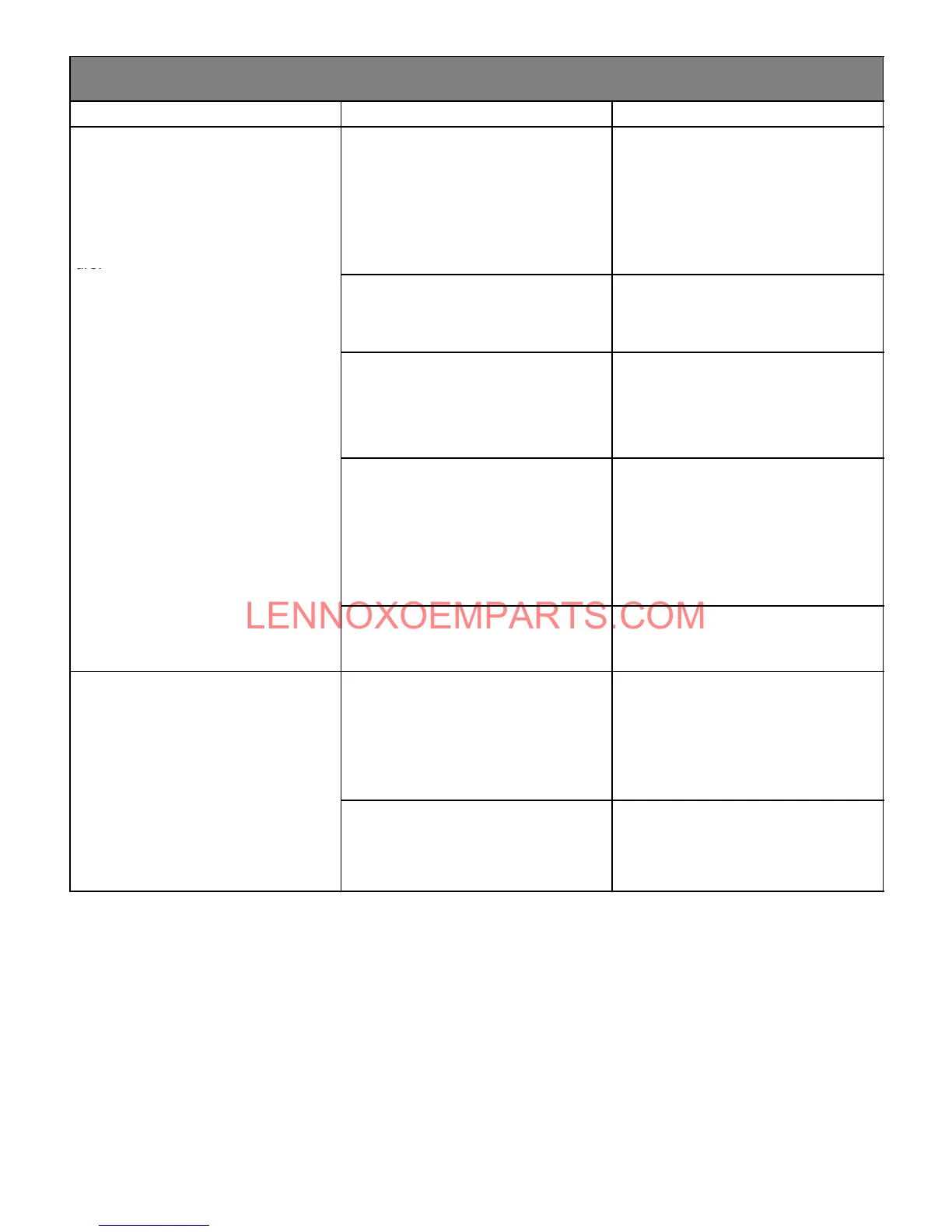

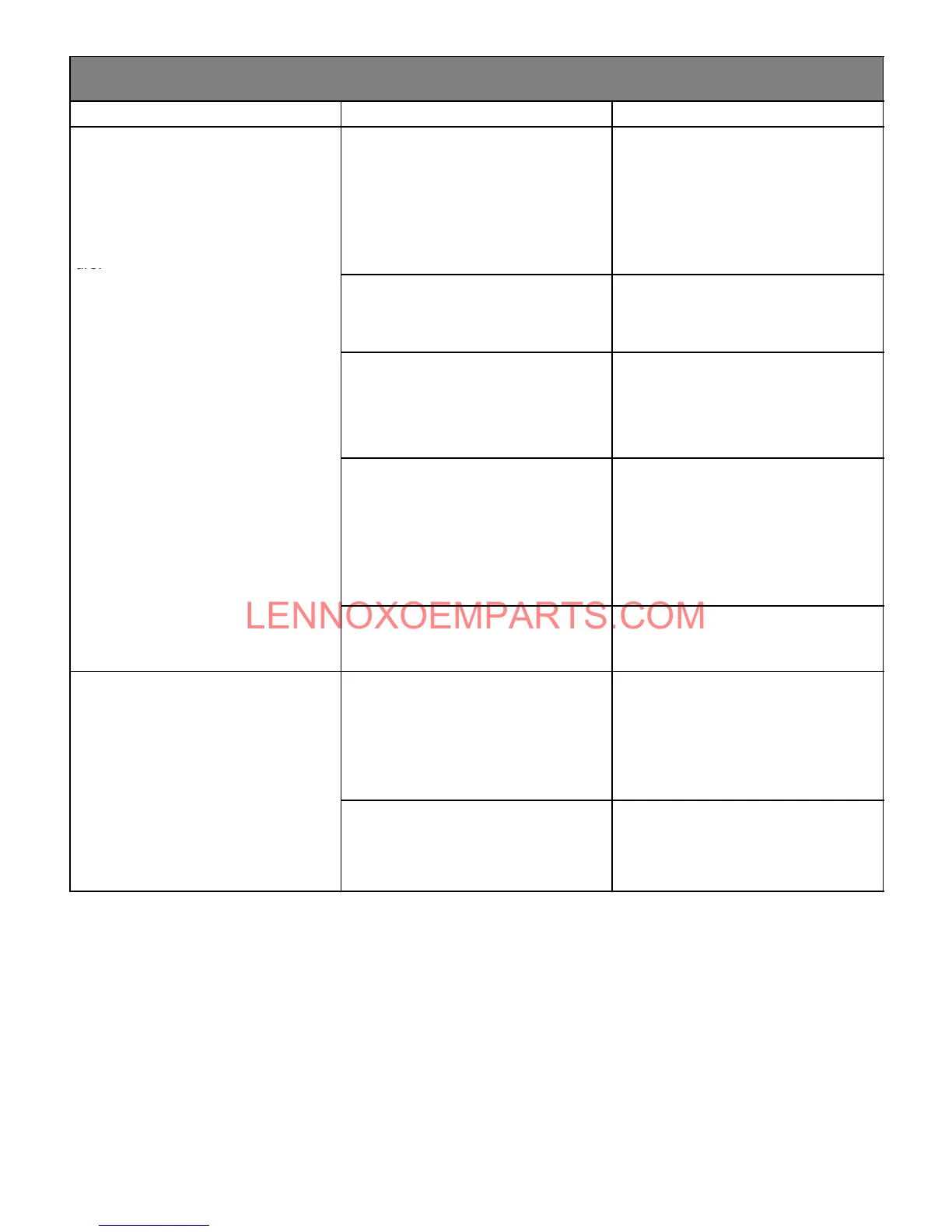

PROBLEM 6: BURNERS LIGHT WITH HEATING DEMAND BUT UNIT SHUTS DOWN

PREMATURELY (CONT.)

Condition Possible Cause Corrective Action/Comments

6.3

- Combustion air blower energizes

with a heating demand.

- Burners light.

- Roll-out switch trips during the

heating demand.

- Diagnostic lights flash roll-out failĆ

ure.

6.3.1

Unit is firing above 100% of the

nameplate input.

ACTION 1 - Check that the manifold pressure

matches value listed on nameplate. See installaĆ

tion instructions for proper procedure.

ACTION 2 - Verify that the installed orifice size

match the size listed on the nameplate or instalĆ

lation instructions.

ACTION 3 - Check gas valve sensing hose to inĆ

sure no leaks are present.

ACTION 4 - Check the input rate to verify rate

matches value listed on nameplate.

LED#1-On

LED#2-Slow Flash

6.3.2

Gas orifices leak at the manifold conĆ

nection.

ACTION 1 - Tighten orifice until leak is sealed.

NOTE: Be careful not to strip orifice threads. ACĆ

TION 2 - Check for gas leakage at the threaded

orifice connection. Use approved method for

leak detection (see unit instructions).

6.3.3

Air leakage at the connections beĆ

tween the primary heat exchanger,

secondary heat exchanger, and comĆ

bustion air blower.

ACTION 1 - Check for air leakage at all joints in

the heat exchanger assembly. Condition will

cause high CO2 with high CO.

ACTION 2 - Seal leakage if possible (high temĆ

perature silicon is recommended), replace heat

exchanger if necessary, tag and return heat exĆ

changer to proper Lennox personnel.

6.3.4

Insufficient flow through the heat exĆ

changer caused by a sooted or reĆ

stricted heat exchanger.

ACTION 1 - Check for sooting deposits or other

restrictions in the heat exchanger assembly.

Clean assembly as outlined in instruction manuĆ

al.

ACTION 2 - For G26 gas furnaces, check for

proper combustion and flow. CO2 should meaĆ

sure between 6.0% and 8.0% for NG and beĆ

tween 7.5% and 9.5% for LP. CO should meaĆ

sure below .04% (400PPM) in an air-free sample

of flue gases for either NG or LP.

6.3.5

Burners are not properly located in

the burner box.

ACTION 1 - Check that the burners are firing into

the center of the heat exchanger openings. CorĆ

rect the location of the burners if necessary.

6.4

- Combustion air blower energizes

with a heating demand.

- Burners light roughly and the unit

fails to stay lit.

- Diagnostic lights flash watchguard

flame failure.

6.4.1

Recirculation of flue gases. This conĆ

dition causes rough ignitions and opĆ

eration. Problem is characterized by

nuisance flame failures.

ACTION 1 - Check for proper flow of exhaust

gases away from intake vent. Remove any obĆ

stacles in front of the intake and exhaust vent

which would cause recirculation.

ACTION 2 - Check for correct intake and exĆ

haust vent installation. See instructions

Loading...

Loading...