Page 1

ã 1998 Lennox Industries Inc.

Corp. 9814-L8

G23(X)

Service Literature

Revised 08-2001

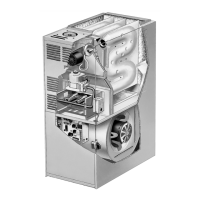

G23(X) SERIES UNITS

G23(X) series units are mid-efficiency upflow gas fur-

naces manufactured with Duralokt aluminized steel

clamshell type heat exchangers. G23(X) units are avail-

able in heating capacities of 50,000 to 150,000 Btuh and

cooling applications up to 6 tons. Refer to Engineering

Handbook for proper sizing.

Units are factory equipped for use with natural gas. A kit is

available for conversion to LPG operation. G23(X)-1, -2, -3

and-4modelunitsuseelectronic (intermittentpilot)ignition.

G23(X)-5 and -6 model units feature the Lennox Sur-

eLightT silicon nitride ignition system. All units meet the

California Nitrogen Oxides (NO

x

) Standards and California

Seasonal Efficiency requirements with the installation of

flame baffles. All units use a redundant gas valve to assure

safety shut-off as required by A.G.A. or C.G.A.

Information contained in this manual is intended for use by

qualified service technicians only. All specifications are

subject to change. Procedures outlined in this manual are

presented as a recommendation only and do not super-

sede or replace local or state codes. In the absence of lo-

cal or state codes, the guidelines and procedures outlined

in this manual (except where noted) are recommended

only.

SPECIFICATIONS

Model No. G23Q2(X)-50 G23Q3(X)-50 G23Q2/3(X)-75 G23Q4/5(X)-75 G23Q3(X)-100

Input Btuh (kW) 50,000 (14.7) 75,000 (22.0) 100,000 (29.3)

Output Btuh (kW) 40,000 (11.7) 61,000 (17.8) 80,000 (23.4)

lA.F.U.E. 80.7% 80.8% 80.4% 80.1%

California Seasonal Efficiency 75.5% 75.6% 76.9% 74.2% 76.6%

Flue size connection diameter— in. (mm) round 3 (76) 4 (102)

Temperature rise range — _F (_C) 30-60 (17-33) 35-65 (19-36) 20-50 (11-28) 45-75 (25-42)

High static certified by A.G.A. — in wg. (Pa) .50 (125)

in. 1/2

Natural or LPG/propane

mm 12.7

in. 10 x 7 10 x 8 11-1/2 x 9 10 x 8

diameter x width

mm 254 x 178 254 x 203 292 x 229 254 x 203

Blower motor output — hp (W) 1/5 (149) 1/3 (249) 3/4 (560) 1/3 (249)

Tons 1 to 2 1 to 3 3-1/2 to 5 1 to 3

that can be added

kW 3.5 to 7.0 3.5 to 10.6 12.3 to 17.6 3.5 to 10.6

Shipping weight — lbs. (kg) 1 package 135 (61) 140 (64) 146 (66) 186 (84) 159 (72)

Electrical characteristics 120 volts — 60 hertz — 1 phase (all models) (less than 12 amps)

lAnnual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces.

}Cleanable polyurethane frame type filter.

Loading...

Loading...