Page 31

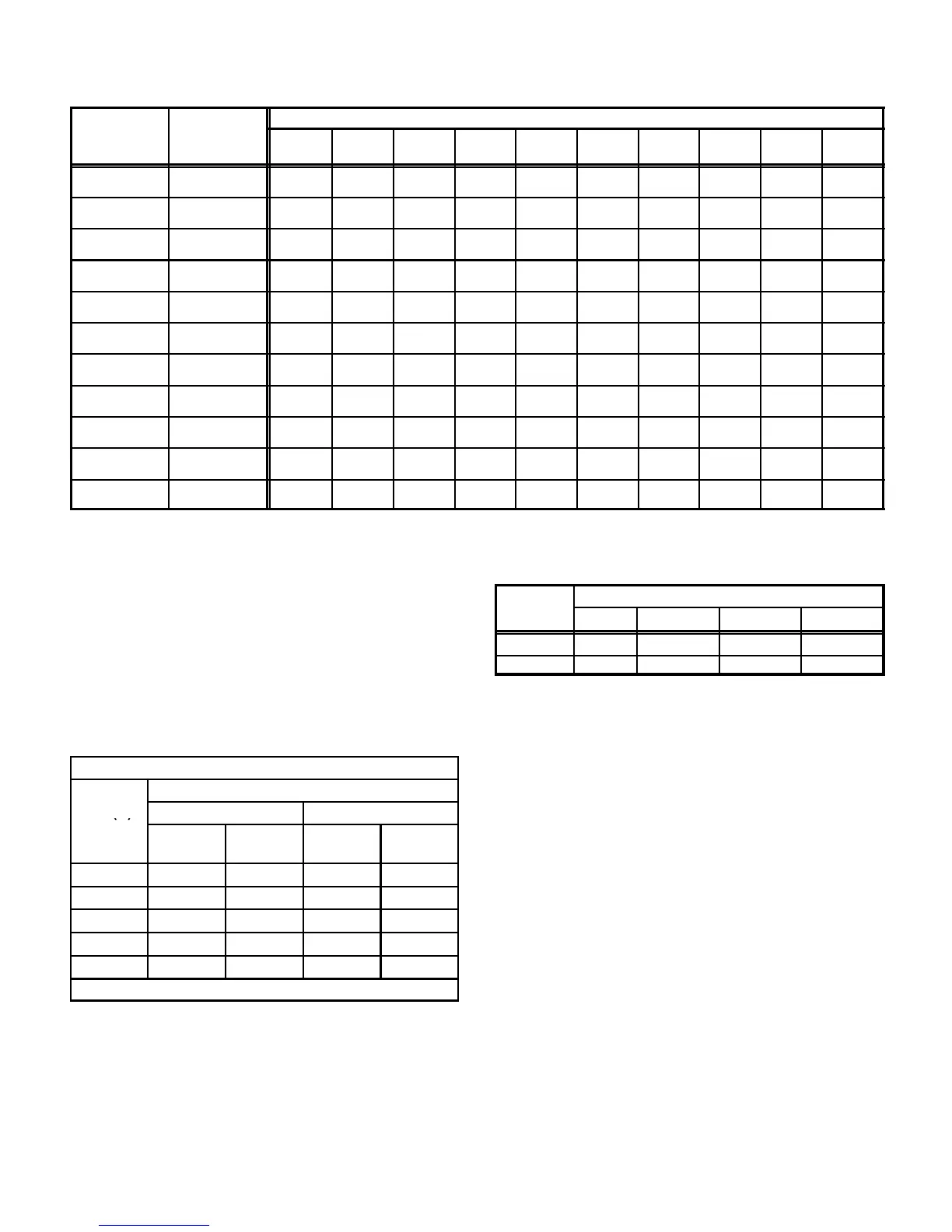

TABLE 16

GAS PIPE CAPACITY - FT

3

/HR (kL/HR)

Length of Pipe-Feet(m)

Iron Pipe Size

-Inches(mm)

Diameter

-Inches(mm)

10

(3.048)

20

(6.096)

30

(9.144)

40

(12.192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30.480)

1/4

(6.35)

.364

(9.246)

43

(1.13)

29

(.82)

24

(.68)

20

(.57)

18

(.51)

16

(.45)

15

(.42)

14

(.40)

13

(.37)

12

(.34)

3/8

(9.53)

.493

(12.522)

95

(2.69)

65

(1.84)

52

(1.47)

45

(1.27)

40

(1.13)

36

(1.02)

33

(.73)

31

(.88)

29

(.82)

27

(.76)

1/2

(12.7)

.622

(17.799)

175

(4.96)

120

(3.40)

97

(2.75)

82

(2.32)

73

(2.07)

66

(1.87)

61

(1.73)

57

(1.61)

53

(1.50)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

250

(7.08)

200

(5.66)

170

(4.81)

151

(4.28)

138

(3.91)

125

(3.54)

118

(3.34)

110

(3.11)

103

(2.92)

1

(25.4)

1.049

(26.645)

680

919.25)

465

(13.17)

375

(10.62)

320

(9.06)

285

(8.07)

260

(7.36)

240

(6.80)

220

(6.23)

205

(5.80)

195

(5.52)

1-1/4

(31.75)

1.380

(35.052)

1400

(39.64)

950

(26.90)

770

(21.80)

660

(18.69)

580

(16.42)

530

(15.01)

490

(13.87)

460

(13.03)

430

(12.18)

400

(11.33)

1-1/2

(38.1)

1.610

(40.894)

2100

(59.46)

460

(41.34)

1180

(33.41)

990

(28.03)

900

(25.48)

810

(22.94)

750

(21.24)

690

(19.54)

650

(18.41)

620

(17.56)

2

(50.8)

2.067

(52.502)

3950

(111.85)

2750

(77.87)

2200

(62.30)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1150

(32.56)

2-1/2

(63.5)

2.469

(67.713)

6300

(178.39)

4350

(123.17)

3520

(99.67)

3000

(84.95

2650

(75.04)

2400

(67.96)

2250

(63.71)

2050

(58.05)

1950

(55.22)

1850

(52.38)

3

(76.2)

3.068

(77.927)

11000

(311.48)

7700

(218.03)

6250

(176.98)

5300

(150.07)

4750

(134.50)

4300

(121.76)

3900

(110.43)

3700

(104.77)

3450

(97.69)

3250

(92.03)

4

(101.6)

4.026

(102.260)

23000

(651.27)

15800

(447.39)

12800

(362.44)

10900

(308.64)

9700

(274.67)

8800

(249.18)

8100

(229.36)

7500

(212.37)

7200

(203.88)

6700

(189.72)

NOTE-Capacity given in cubic feet of gas per hour (kilo liters of gas per hour) and based on 0.60 specific gravity gas.

F- Proper Gas Flow (Approximate)

Furnace should operate at least 5 minutes before check-

ing gas flow. Determine time in seconds for two revolu-

tions of gas through the meter. (Two revolutions assures

a more accurate time.) Divide by two and compare to time

in table 17 below. Adjust manifold pressure on gas valve

to match time needed.

NOTE- To obtain accurate reading, shut off all other

gas appliances connected to meter.

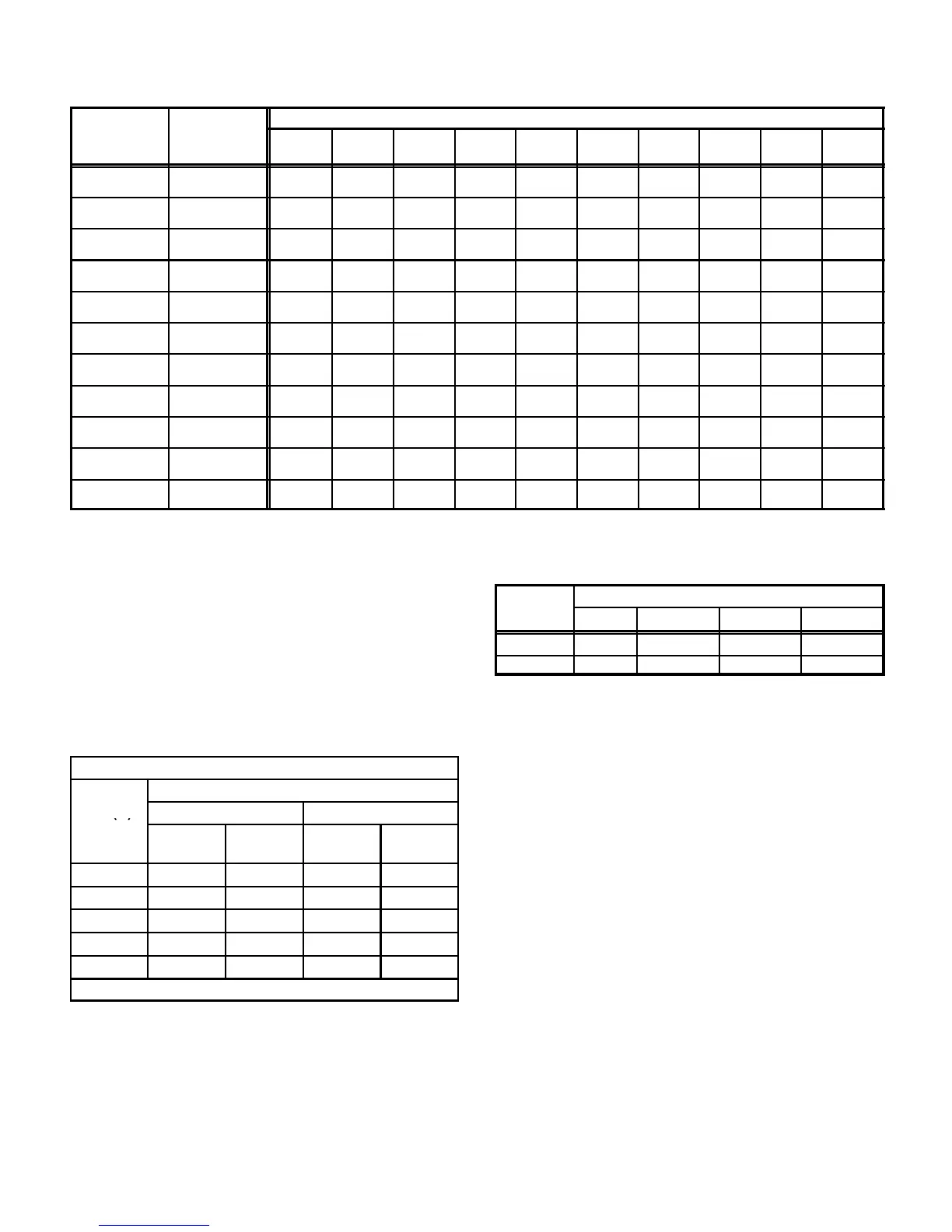

TABLE 17

GAS METER CLOCKING CHART

Seconds for One Revolution

G23(X)

Natural LP

Unit

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

-50 72 144 180 360

-75 48 96 120 240

-100 36 72 90 180

-125 29 58 72 144

-150 24 48 60 120

Natural-1000 btu/cu ft LP-2500 btu/cu ft

G-High Altitude Derate

Pressure regulator may need to be adjusted, depending

on altitude. See table 18 for proper pressure regulator set-

ting.

TABLE 18

Manifold Absolute Pressure (Outlet) in. w.c.

ALTITUDE

0 - 4500 4501 - 5500 5501 - 6500 6501 - 7500

NAT. GAS 3.5 3.3 3.1 3.0

L.P. GAS 10.0 10.0 10.0 10.0

A natural to LP/propane gas changeover kit is required to

convert unit. Refer to the installation instructions supplied

with the changeover kit for conversion procedure.

The pressure switch is factory set. No adjustment is nec-

essary. The G23-50/75 units use the factory pressure

switch from 0 to 7500 feet. G23-100/125 and G23-150

units require a high altitude pressure switch for units

installed above 5000 feet. Order Lennox part number

97J50 for G23-100/125 and 18J35 for G23-150.

H-Flame Signal

A microamp DC meter is needed to check the flame signal

on the ignition control.

Flame (microamp) signalis an electricalcurrent which passes

from the furnace control through the sensor during unitopera-

tion. Current passes from the sensor through the flame to

ground to complete a safety circuit.

Loading...

Loading...