Do you have a question about the Lennox G23Q3-50 and is the answer not in the manual?

Overview of the G23(X) series furnaces, including heating and cooling capacities.

Air volume and motor watts at specific blower taps for the G23Q2(X)-50 model.

Air volume and motor watts at specific blower taps for the G23Q2/3(X)-75 model.

Air volume and motor watts at specific blower taps for the G23Q3/4(X)-100 model.

Air volume and motor watts at specific blower taps for the G23Q5/6(X)-150 model.

Table showing air resistance (in. w.g.) for various CFM (L/S) values.

List of optional accessories available for G23(X) furnaces.

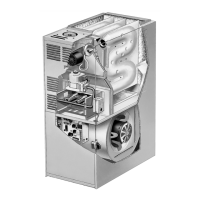

Diagram illustrating the general parts layout of the G23(X) furnace.

Diagram of control box for -5 and -6 G23X models.

Details of control box components including transformer and circuit breaker.

Instructions for installing the make-up box for electrical connections.

Description of the BCC blower control used in -1 through -4 models.

Safety precautions for handling electronic components to prevent electrostatic discharge.

Explanation of the furnace's normal heating operation sequence.

Details on the intermittent pilot ignition control for specific models.

Explanation of the diagnostic LED functions for troubleshooting the ignition control.

Table of blower motor horsepower and capacitor ratings for G23(X) units.

Arrangement and function of pilot, spark electrode, flame sensor and burners.

Description of the SureLight ignition system for specific G23(X) models.

Details on the electronic ignition sequence and control logic.

Information on the gas valve, its types, and replacement procedures.

Guidelines for ensuring adequate fresh air for combustion and ventilation.

Requirements for bringing combustion air from an unconfined space into a confined one.

Guidelines for proper flue venting and compliance with codes.

Information on vent diameter, capacity, and connector sizing.

Checks to perform before unit start-up, including wiring and voltage.

Procedures for checking gas supply pressure and piping.

Procedure to check and adjust manifold pressure for proper unit operation.

Guidelines for blower operation and measurement of external static pressure.

Instructions for changing blower speed taps on leadless and leaded motors.

Instructions for inspecting, cleaning, and replacing furnace filters.

Operation sequence for G23(X) models -1, -2, -3, and -4.

Flowchart for diagnosing issues with the BCC blower control.

Troubleshooting steps when spark is present but the pilot does not light.

Troubleshooting steps when there is no spark and the system does not work.

Troubleshooting steps when pilot lights but the main valve does not open.

Sequence of operation for the SureLight control during normal heating.

Sequence of operation for the SureLight control during abnormal heating.

Sequence of operation for the SureLight control during normal cooling.

Sequence of operation for continuous low speed fan mode.

Troubleshooting guide for unit failure to operate in cooling, heating, or fan modes.

Diagnosing issues when the unit fails to operate in cooling, heating, or fan modes.

Diagnosing failure to fire when combustion air blower does not energize.

Diagnosing issues when burners light but unit shuts down prematurely.

Loading...

Loading...