3DJH

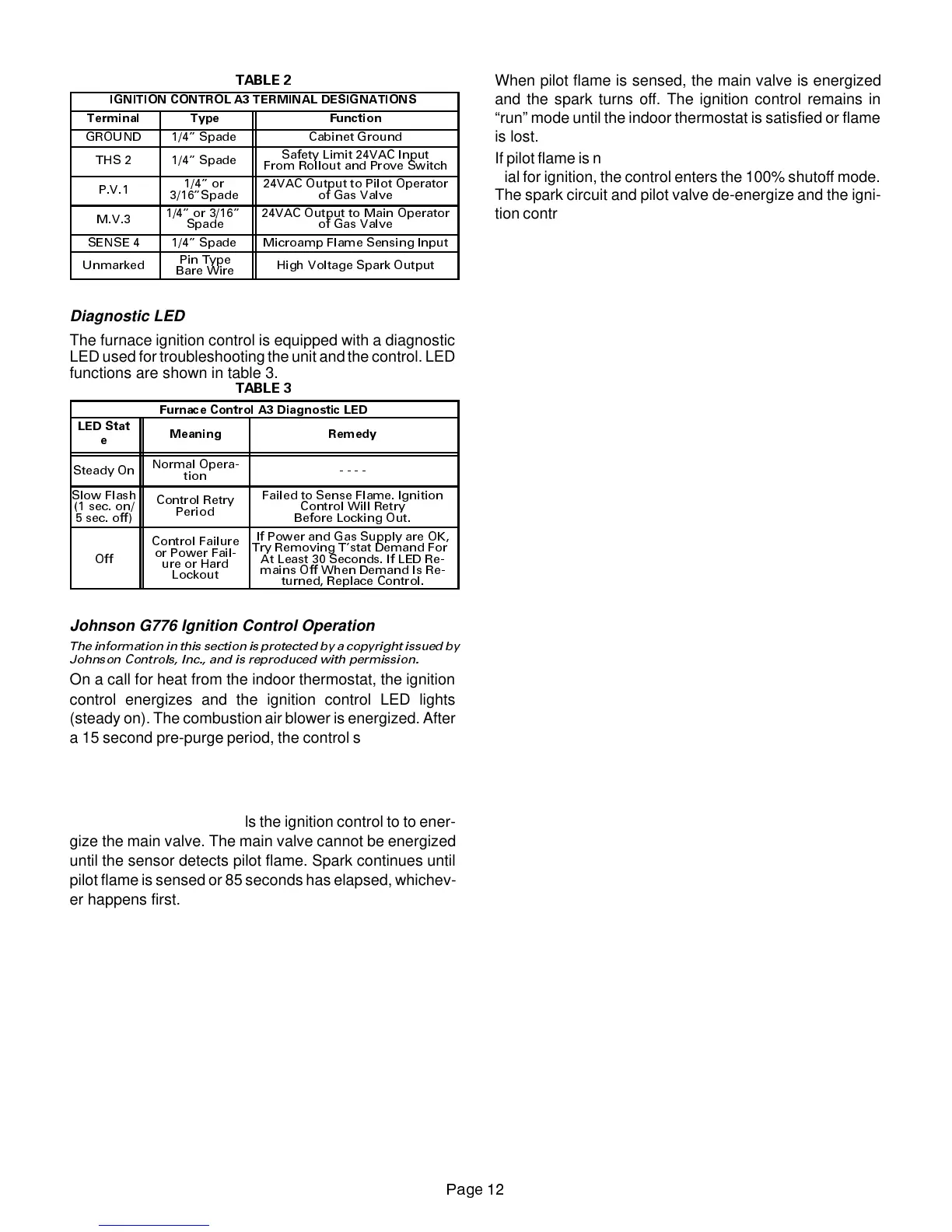

TABLE 2

IGNITION CONTROL A3 TERMINAL DESIGNATIONS

Terminal Type Function

GROUND 1/4 Spade Cabinet Ground

THS 2 1/4 Spade

Safety Limit 24VAC Input

From Rollout and Prove Switch

P.V.1

1/4 or

3/16Spade

24VAC Output to Pilot Operator

of Gas Valve

M.V.3

1/4 or 3/16

Spade

24VAC Output to Main Operator

of Gas Valve

SENSE 4 1/4 Spade Microamp Flame Sensing Input

Unmarked

Pin Type

Bare Wire

High Voltage Spark Output

Diagnostic LED

The furnace ignition control is equipped with a diagnostic

LED used for troubleshootingthe unit andthe control. LED

functions are shown in table 3.

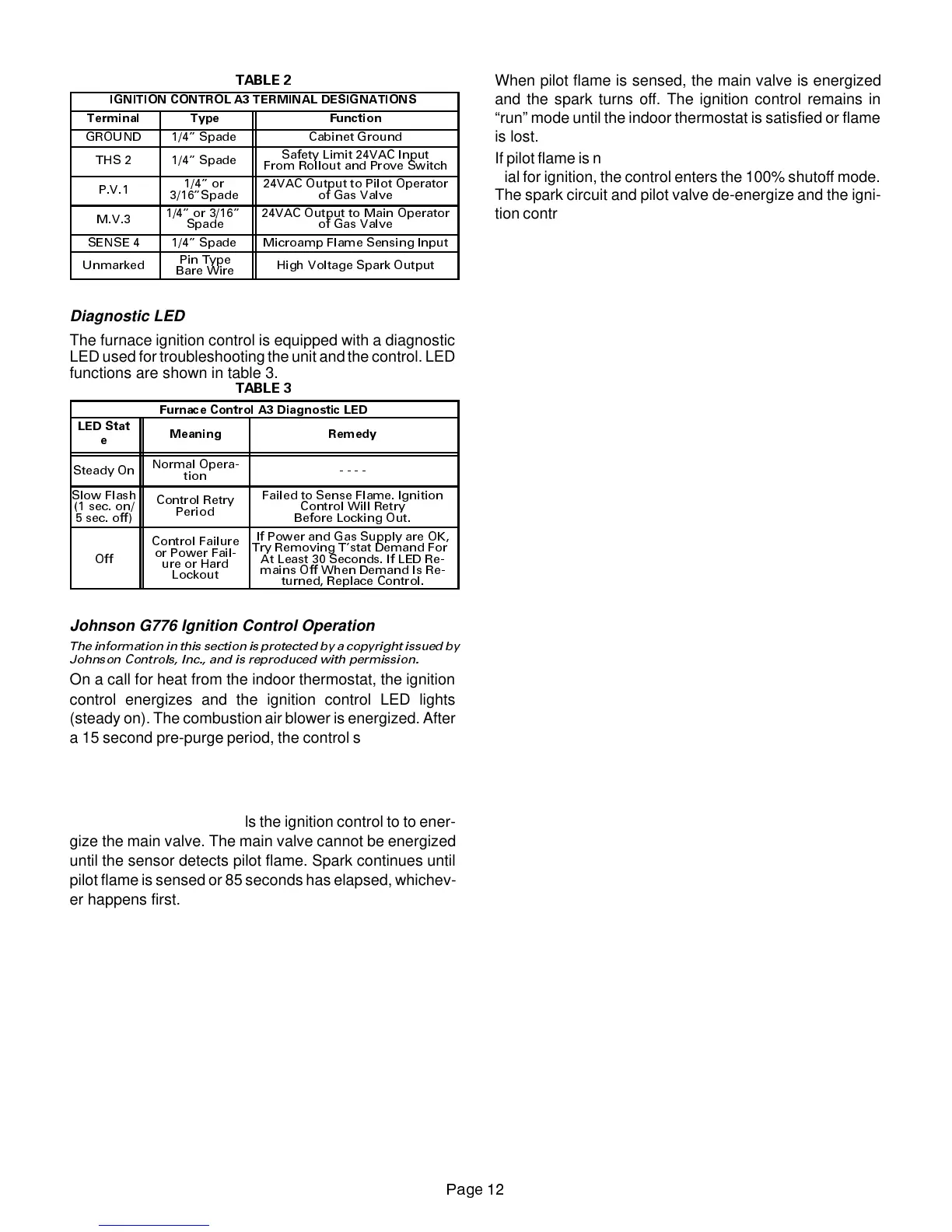

TABLE 3

Furnace Control A3 Diagnostic LED

LED Stat

e

Meaning Remedy

Steady On

Normal Opera-

tion

----

Slow Flash

(1 sec. on/

5 sec. off)

Control Retry

Period

Failed to Sense Flame. Ignition

Control Will Retry

Before Locking Out.

Off

Control Failure

or Power Fail-

ure or Hard

Lockout

If Power and Gas Supply are OK,

Try Removing Tstat Demand For

At Least 30 Seconds. If LED Re-

mains Off When Demand Is Re-

turned, Replace Control.

Johnson G776 Ignition Control Operation

The information in this section is protected by a copyright issued by

Johnson Controls, Inc., and is reproduced with permission.

On a call for heat from the indoor thermostat, the ignition

control energizes and the ignition control LED lights

(steady on). The combustion air blower is energized. After

a 15 second pre-purge period, the control simultaneously

opens the pilot valve and sends spark to the pilot elec-

trode.

If the pilot ignites within 85 seconds, the flame sensor de-

tects pilot flame and signals the ignition control to to ener-

gize the main valve. The main valve cannot be energized

until the sensor detects pilot flame. Spark continues until

pilot flame is sensed or 85 seconds has elapsed, whichev-

er happens first.

When pilot flame is sensed, the main valve is energized

and the spark turns off. The ignition control remains in

“run” mode until the indoor thermostat is satisfied or flame

is lost.

If pilot flame is not sensed before the end of the 85 second

trial for ignition, the control enters the 100% shutoff mode.

The spark circuit and pilot valve de-energize and the igni-

tion control automatically begins the 60 minute retry delay

period. During the 60 minute delay the diagnostic LED

continually flashes on for one second and off for five se-

conds. After the delay period, another trial for ignition se-

quence starts, beginning with pre-purge.

If pilotflame goes out while theindoor thermostat is calling

for heat, both main and pilot valves de-energize within 0.8

seconds and remain de-energized for five seconds. After

this delay, the spark and pilot valve energize until flame is

sensed or the85second trial for ignitionperiodends.Ifthis

“flameout” cycle repeats 16 times (pilot flame is estab-

lished and then lost), the control locks out and the LED

goes off. A new trial for ignition sequence begins after the

thermostat contacts are opened for 30 seconds and then

closed.

If flame is detected when the thermostat calls for heat, it

must extinguish within 30 seconds for normal operation. If

flameis still present after 30 seconds, the control goes into

lockout and the LED goes off.

D-Combustion Air Blower (B6)

All G23(X) units use a combustion air blower to move air

through the burners and heat exchanger during heating op-

eration. The blower uses a shaded pole 120VAC motor.

Shaded pole motors do not use run capacitors. The motor

operates during all heating operation and is controlled by

blower control A15. The blower operates continuously while

there is a call for heat. The ignition control is prevented from

proceeding through the ignition sequence until combustion

air blower operation is sensed by the prove switch.

The pressure switch connected to the upper vest panel is

used to prove combustion air blower operation. The switch

monitors air pressure in the blower housing. During normal

operation, the pressure in the housing is negative. If the

pressure drops (becomes more positive), the pressure

switch opens. When the pressure switch opens, the ignition

control (A3) immediately closes the gas valve to prevent

burner operation.

Loading...

Loading...