3DJH

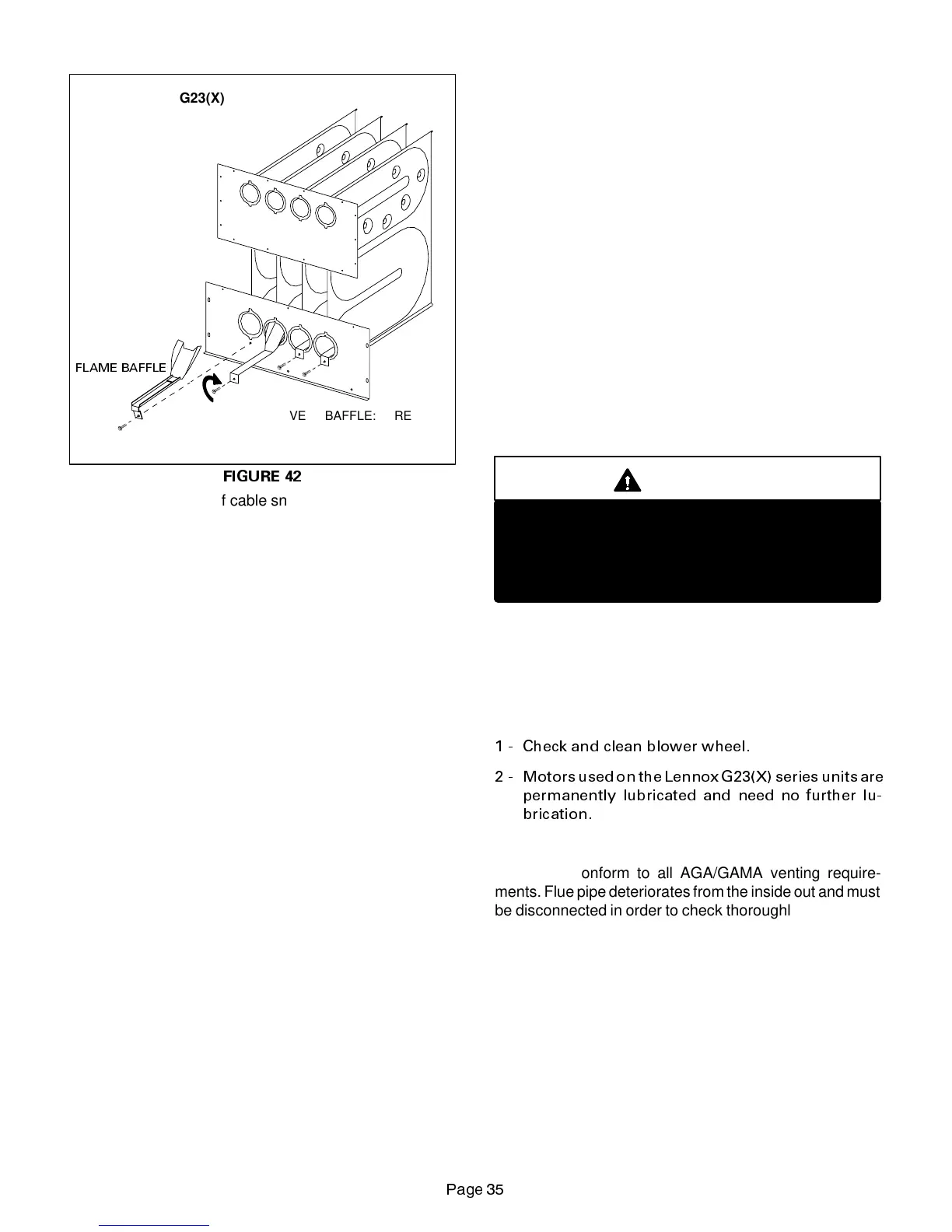

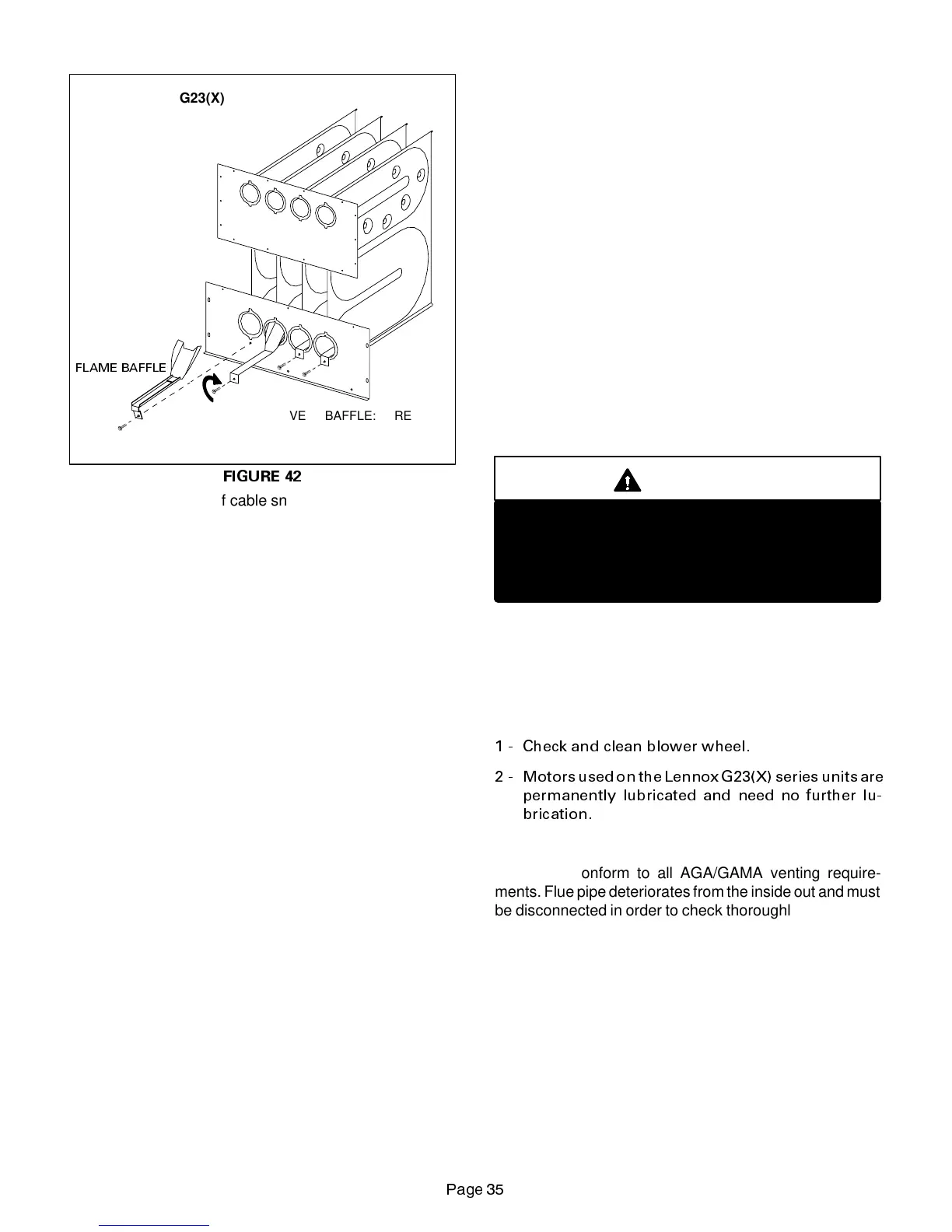

G23(X) FLAME BAFFLES

(NOx UNITS ONLY)

FLAME BAFFLE

TO REMOVE BAFFLE: REMOVE

SCREW. ROTATE BAFFLE AS SHOWN

AND REMOVE FROM HEAT EXCHANG-

ER

FIGURE 42

9 - Insert brush end of cable snake into top of one of the

heat exchanger openings. DO NOT FORCE CABLE

INTO HEAT EXCHANGER. Once the cable has been

inserted, operate drill on slow speed. Move the cable

in and out of the heat exchanger section three or four

times or until sufficient cleaning is accomplished. Re-

verse drill and slowly work cable out of opening.

10- Repeat procedure for each heat exchanger section.

11- When the top heat exchanger sections are complete,

place brush end of cable snake into the bottom openings

of each of the heat exchanger sections. Clean the bottom

opening as described in step 9.

12- Remove cable from heat exchanger. Use a vacuum to

remove debris knocked loose during cleaning from

each heat exchanger section.

13- Attach the exhaust end (positive pressure) of the

vacuum to the top of the heat exchanger sections.

Any loose debris will be forced to the bottom of the

heat exchanger section. Vacuum debris from bot-

tom openings.

14- Replace collector box and combustion air blower.

Check gaskets for damage. Damaged seals must be

replaced to avoid heat exchanger leaks. Replace all

screws to the collector box and combustion air blower.

Leaving off screws may cause leaks.

15- Replace upper vestibule panel, top cap, pressure

switch and ignition control.

16- Clean burner by running a vacuum with a soft brush at-

tachment over face of burners. Visually inspect inside of

burners and crossovers for any blockage caused by for-

eign matter. Remove any blockage.

17- For NOX units, replace flame baffles in each heat ex-

changer section. DO NOT BEND baffles. Baffles

should sit on the bottom of each heat exchanger sec-

tion.

18- Replace burner / manifold assembly onto lower vesti-

bule panel.

19- Reconnect wires to ignition control (-1 through -4 mod-

el units), pressure switch, roll-out switch, gas valve and

combustion air blower. Refer to unit wiring diagram.

20- Reconnect vent pipe to combustion blower outlet.

21- Reconnect gas supply piping.

22- Turn on power and gas supply to unit.

23- Set thermostat and check for proper operation.

24- Check all piping connections, factory and field, for gas

leaks. Use a leak detecting solution or other preferred

means.

CAUTION

Some soaps used for leak detection are corrosive

tocertainmetals.Carefullyrinsepiping thorough-

ly after leak test has been completed. Do not use

matches, candles, flame or other sources of igni-

tion to check for gas leaks.

25- Ifa leakisdetected, shut gas and electricityoff and

repair leak.

26- Repeat steps 23 and 24 until no leaks are detected.

27- Replace front access panel.

C-Supply Air Blower

1 - Check and clean blower wheel.

2 - Motors used on the Lennox G23(X) series units are

permanently lubricated and need no

further lu-

brication.

D-Flue and Chimney

Flue must conform to all AGA/GAMA venting require-

ments. Flue pipedeteriorates from the insideout and must

be disconnected in order to check thoroughly. Check flue

pipe, chimney and all connections for tightness and to

make sure there is no blockage or leaks.

E-Electrical

1 - Check all wiring for loose connections.

2 - Check for correct voltage.

3 - Check amp-draw on blower motor.

Loading...

Loading...