Page 19

FIGURE 14

SECONDARY LIMIT

GCS16-410-100 AND GCS16R-411-100 ONLY

BLOWER

SECONDARY LIMIT

LOCATION

6-Flame Rollout Switch S47

Flame rollout switch S47 is a high temperature limit lo

cated just above the burner air intake opening in the burn

er enclosure (see figure 12). The limit is a N.C. SPST re

settable limit connected in series with ignition control A3.

When S47 senses flame rollout, the ignition control imme

diately stops ignition and closes the gas valve. The switch

is factory set and cannot be adjusted.

Initially, only units equipped with a burner enclosure were

equipped with rollout switch S47 (see section 3- Burner

Enclosure and figure 12). In November 1989, rollout

switch was added to all units. It is an A.G.A. mandated re

quirement on all gas furnaces produced after that date. In

all 75,000, 100,000 and 125,000 Btuh heat exchanger

units produced after November 1989, the switch is

installed in a burner enclosure as shown in figure 12. In all

50,000 Btuh heat exchanger units produced after Novem

ber 1989, the switch is installed as shown in figure 8.

7-Combustion Air Prove Switch S18

The combustion air prove switch (S18) is a SPST N.O. dif

ferential pressure switch used to monitor combustion air

blower operation. A flexible hose connects one side of the

switch to the blower housing. The other side of the switch

is open to the atmosphere. The switch is wired in series

with ignition control A3. Prove switch S18 closes when the

combustion air blower reaches full speed to allow the igni

tion control to energize. This proves that the combustion

air blower is operating and allows the heating cycle to con

tinue.

The combustion air prove switch is factory set and is not

adjustable. Factory settings are shown in Table 3.

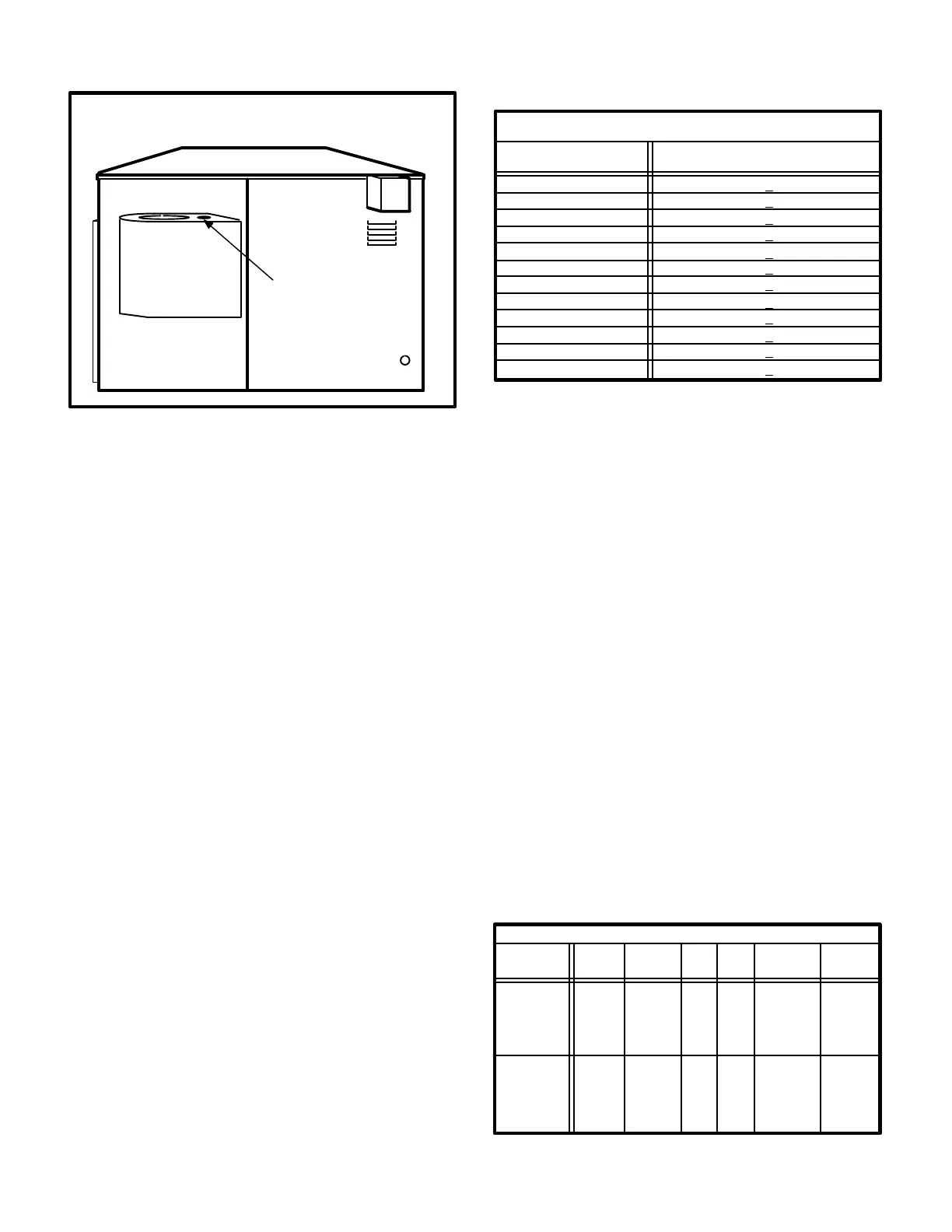

COMBUSTION AIR PROVE SWITCH

FACTORY SETTING

TABLE 3

Unit

inches w.c.

N.O., closes on pressure drop

GCS16H-261

GCS16H-311

0.45 + 0.05

0.65 + 0.05

GCS16-411/413-100 0.45 + 0.05

GCS16-511/513-125 0.90 + 0.05

GCS16-651/653-75

GCS16R-650-125

0.45 + 0.05

0.90 + 0.05

GCS16R-411-100 0.65 + 0.05

GCS16-411/413-50 0.45 + 0.05

GCS16R-411-50 0.45 + 0.05

GCS16R-651-75 0.45 + 0.05

GCS16R-511-125 0.90 + 0.05

GCS16-651/653-125 0.90 + 0.05

8-Combustion Air Blower B6

Combustion air blower B6 provides fresh air to the burner

while clearing the combustion chamber of exhaust gases.

The blower begins operating immediately upon receiving

a thermostat demand and is deenergized immediately

when thermostat demand is satisfied.

Blowers on 50K, 75K and 100K Btuh heat exchangers are

manufactured by Lennox and can be disassembled for

cleaning. Blowers on 125K Btuh heat exchangers are fac

tory assembled as a unit and cannot be disassembled for

cleaning.

Combustion air blower specifications are shown in table 4.

All combustion air blower motors are sealed and cannot be

oiled.

The tube connecting the switch to the blower flue box must

be sloped in a manner that will prevent condensate from

collecting in the tube. It is normal for a small amount of

condensate to form in the tube during unit operation. The

tube and switch must be allowed to drain accumulated

condensate between thermostat demands. If the tube is

positioned so that accumulated condensate is trapped in

the tube, the unit may run improperly or may lock out.

TABLE 4

COMBUSTION AIR BLOWER

Unit Input

Btuh

Type HP RPM

Volts/

phase

Bearings Misc.

50K

75K

100K

125K

208/

230/1

Shaded

Pole

1-1/2

Stack

1/25 3200 Ball

Requires

T3 when

used in

460/575

volt units

208/

230/1

Requires

T3 when

used in

460/575

volt units

Ball32001/10PSC

Loading...

Loading...