Page 21

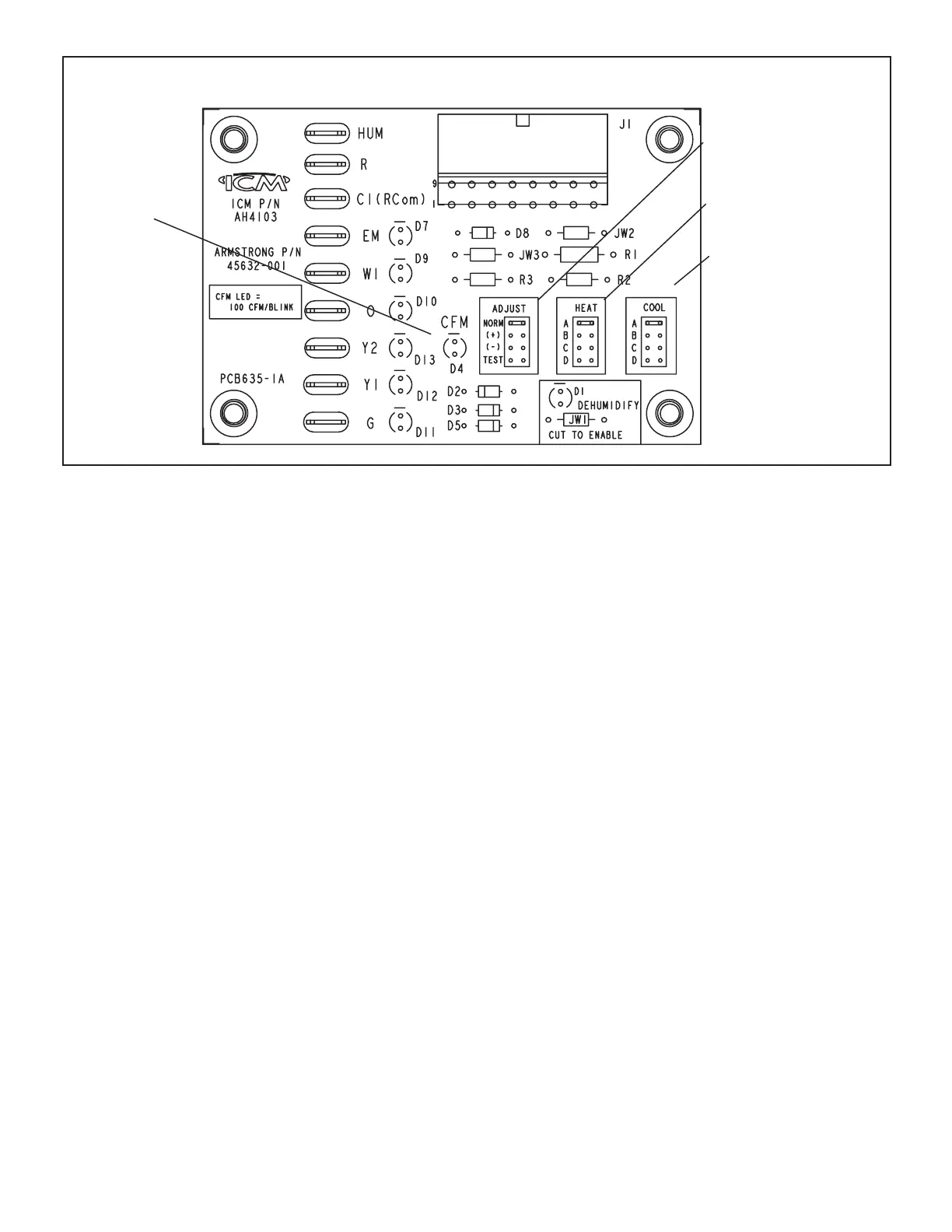

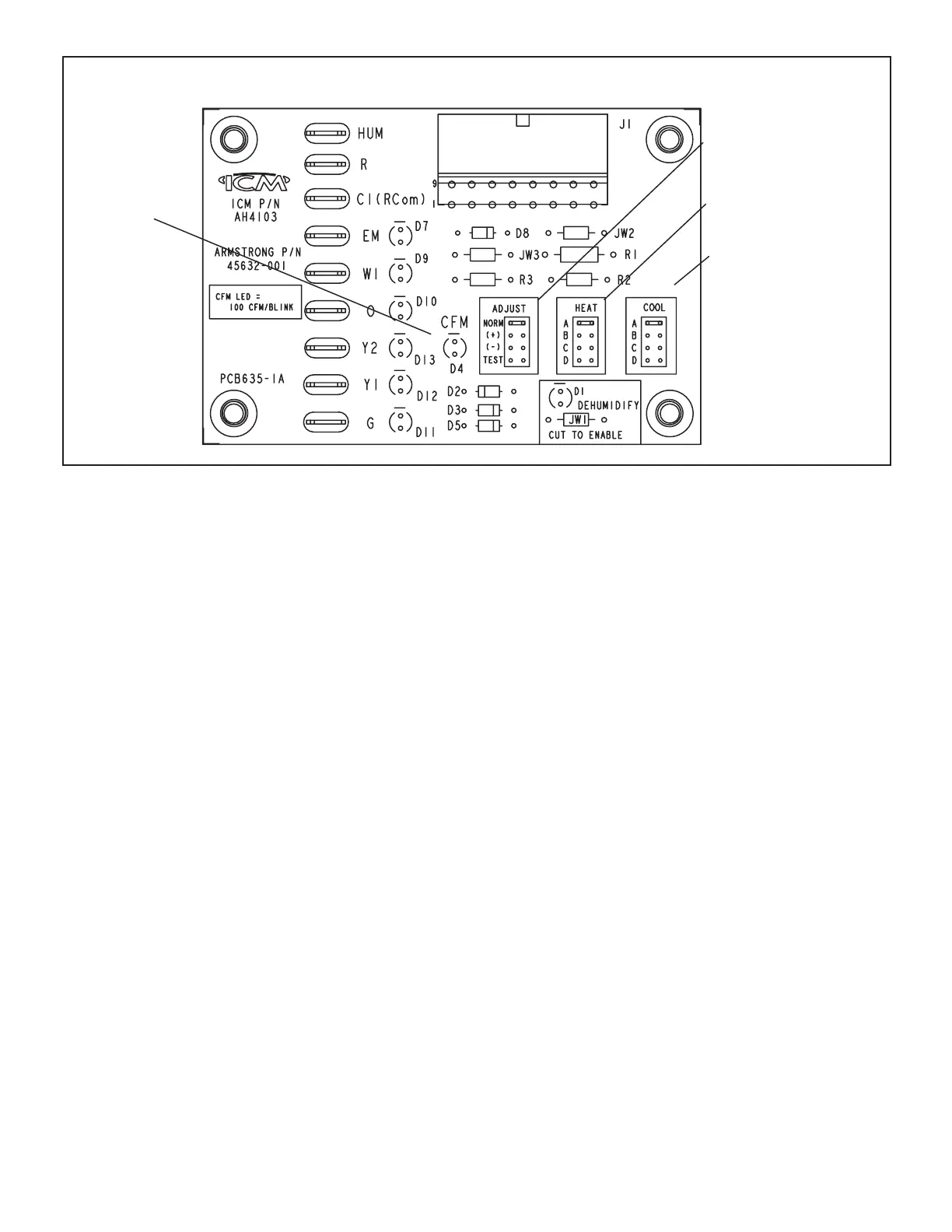

BLOWER CONTROL BOARD (A54) – LRP16 UNITS

(Setting affects both heat−

ing and cooling modes)

DIAGNOSTIC

LED

HEATING SPEED

SELECTOR PINS

COOLING SPEED

SELECTOR PINS

SELECTOR PINS

ADJUST

FIGURE 9. Blower Control Board (A54) – ECM Motor – LRP16GE / LRP16HP

Blower Control – Units with Constant Torque Motors

LRP14 units that are equipped with constant torque blow-

er motors are energized from the W, G and Y 24 volt ter-

minals from the room thermostat, which are connected to

the control board in each unit. The constant torque mo-

tor is capable of maintaining a specied CFM throughout

the external static range. Constant torque units are not

equipped with a separate blower control.

BLOWER SPEED ADJUSTMENT / OPERATION LRP14

UNITS

Blower Speeds – Constant Torque Units

Fan speed on units equipped with constant torque motors

is eld-adjustable. See blower CFM chart for unit size.

Blower Speeds — LRP16GE/HP Units

Fan speed on the HEAT and COOL stage air volume se-

lections are made by jumper pins.

Continuous Fan Operation

When the thermostat is set for “Continuous Fan” operation

and there is no demand for heating or cooling, the blower

on units with PSC motors will operate at cooling speed.

On units with constant torque motors, the blower will oper-

ate at low speed with a G call.

NOTE - With the proper thermostat and sub-base, con-

tinuous blower operation is possible by closing the R to

G circuit. Cooling blower delay is also functional in this

mode.

Blower Control Board (A54) LRP16GE/HP Units

These units are equipped with a variable-speed motor

which is controlled by a blower control board. See gure

11.

On LRP16GE/HP units equipped with ECM motor and a

two-stage electronic blower control, the indoor blower is

energized by the ignition control.

The variable speed motor that is capable of maintaining

a specied CFM throughout the external static range. A

particular CFM can be obtained by positioning jumpers

(COOL, HEAT, and ADJUST) on the blower control board.

The HEAT and COOL jumpers are labeled A, B, C and D.

Each of the letters corresponds with an air volume (CFM)

setting. The ADJUST jumper is labeled NORM, +, - and

Test. The + and - pin settings are used to add or subtract a

percentage of the CFM selected. The Test jumper is used

to operate the motor in the test mode. See gure 11.

Factory settings for the blower speed jumpers are given in

the wiring diagram in gure 11. Use the blower data tables

in this manual to determine the correct air volume for op-

eration in heat and cool mode.

The CFM LED located on the blower control board ashes

one time per 100 cfm to indicate selected blower speed.

For example, if the unit is operating at 1000 CFM, CFM

LED will ash 10 times. If the CFM is 1150, CFM LED will

ash 11 full times plus one fast or half ash.

Loading...

Loading...