Page 12

HEATING COMPONENTS

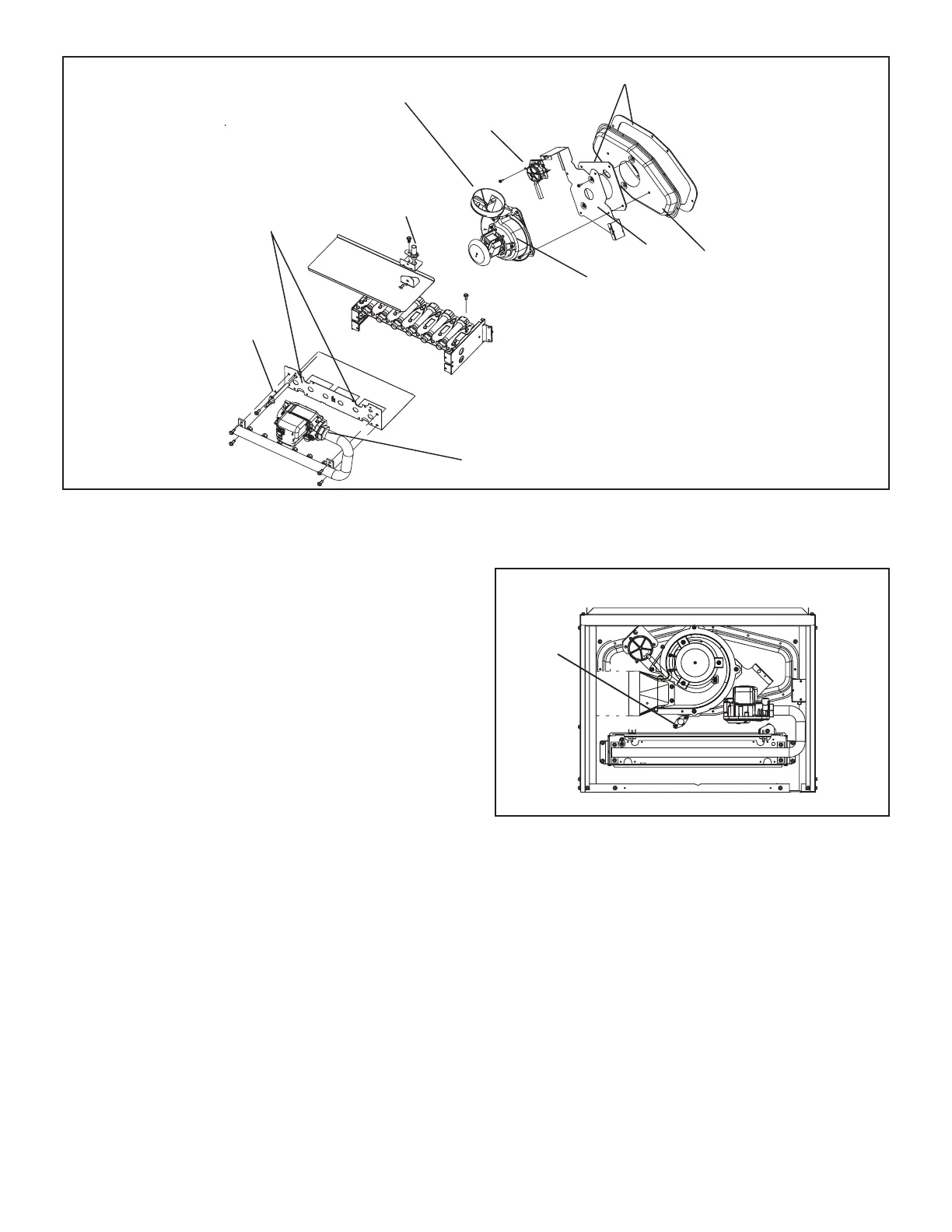

Gaskets

Collector Box

Orifice Plate

Flue Transition

Pressure Switch

Combustion Air Inducer

Manifold And Gas Valve

Ignitor

Sensor

Rollout Switches

FIGURE 6

5. Flame Rollout Switches (Figure 6)

Flame rollout switch (S47) is a high temperature limit.

Each furnace is equipped with two identical switches. The

limit is a N.C. SPST manual-reset limit connected in series

with the integrated control A92. When S47 senses rollout,

the integrated control immediately stops ignition and clos-

es the gas valve. If unit is running and ame rollout is de-

tected, the gas valve will close and integrated control will

be disabled. Rollout can be caused by a blocked heat ex-

changer, blocked ue or lack of combustion air. The switch

has a factory setpoint of 210°F and cannot be adjusted.

To manually reset a tripped switch, push the reset button

located on the control.

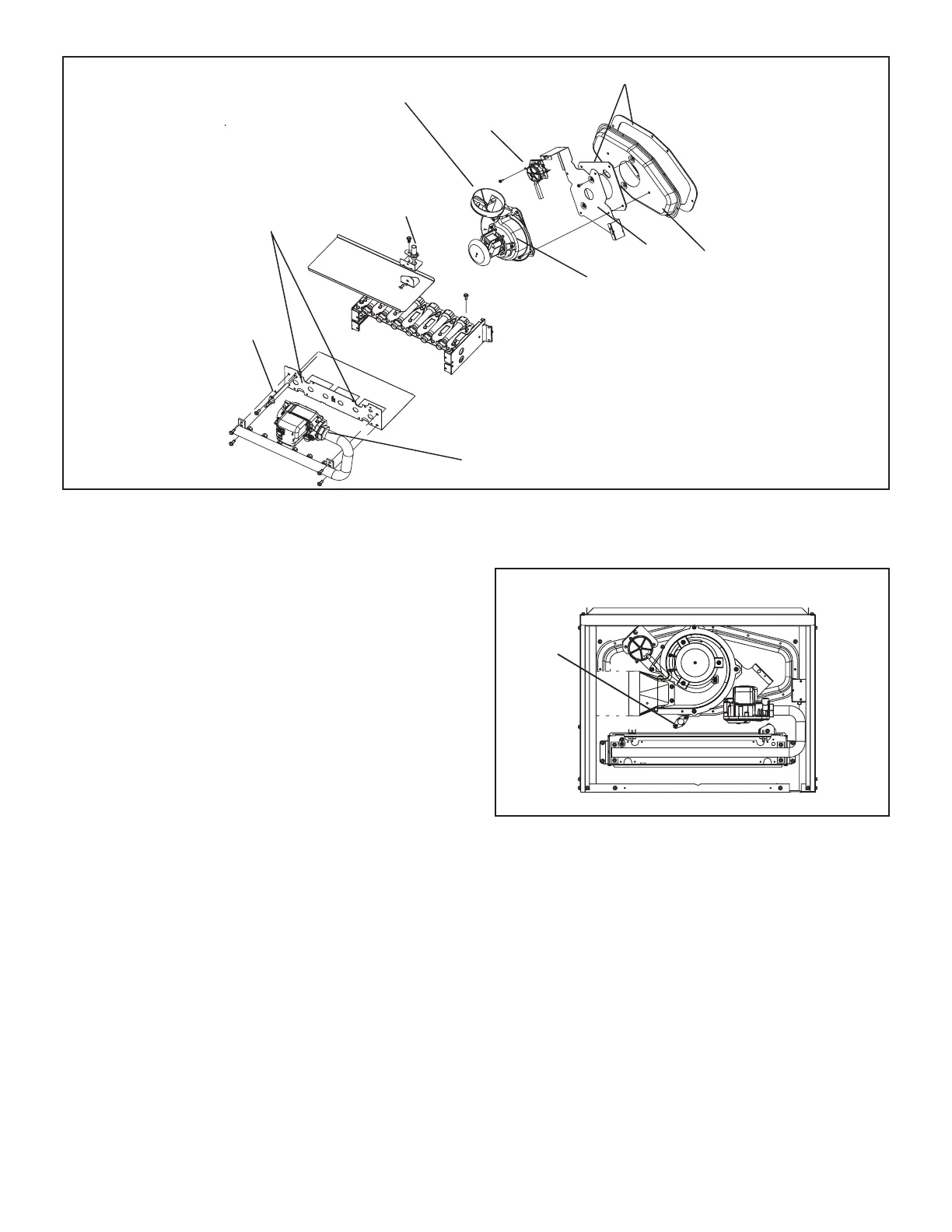

6. Primary Limit Control

The primary limit on ML180UHE(X) units is located in the

heating vestibule panel under the combustion air induc-

er. See gure 7. When excess heat is sensed in the heat

exchanger, the limit will open. If the limit is open, the in-

tegrated control energizes the supply air blower and clos-

es the gas valve. The limit automatically resets when unit

temperature returns to normal.

The switch must reset within three minutes or SureLight®

control will go into Watchguard for one hour. The switch is

factory set and cannot be adjusted. The switch may have

a dierent setpoint for each unit model number. If limit

switch must be replaced, refer to Lennox ProductZone re-

pair parts list.

Primary Limit Under Combustion Air Inducer

Primary

Limit

FIGURE 7

7. Flame Sensor (Figure 6)

A ame sensor is located on the left side of the burner sup-

port. The sensor is mounted on the ame rollout plate and

the tip protrudes into the ame envelope of the left-most

burner. The sensor can be removed for service (clean

with steel wool) without removing any part of the burn-

ers. During operation, ame is sensed by current passed

through the ame and sensing electrode. The integrated

control allows the gas valve to remain open as long as

ame signal is sensed.

A microamp DC meter is needed to check the ame signal

on the integrated control.

Loading...

Loading...