Page 21

II- PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

III- START-UP

A- Heating Start-Up

WARNING

Shock and burn hazard.

ML180UHE(X) units are equipped with a hot surface

ignition system. Do not attempt to light manually.

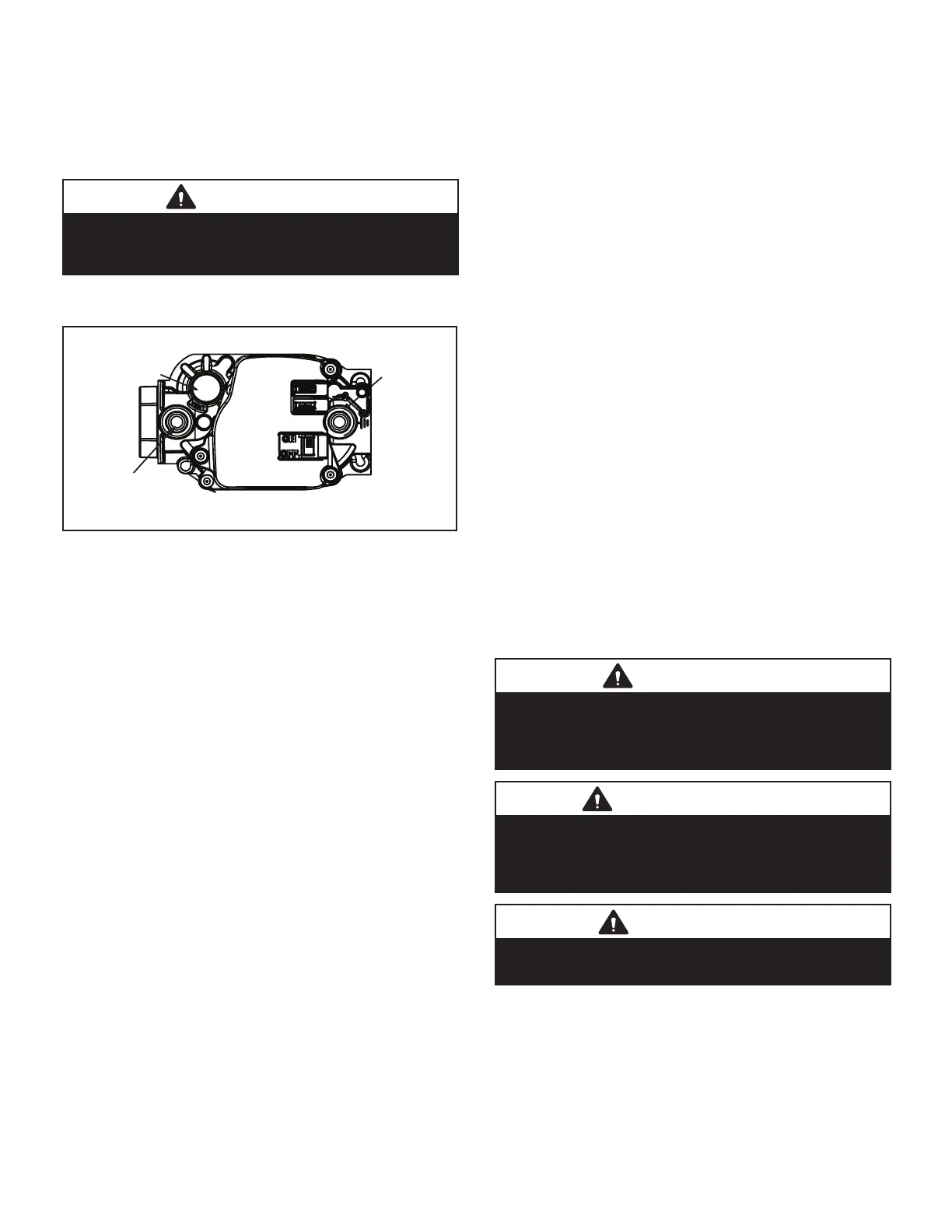

Gas Valve Operation

GAS VALVE SHOWN IN ON POSITION

MANIFOLD

PRESSURE

OUTLET

PORT

INLET

PRESSURE

PORT

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

FIGURE 19

1 - STOP! Read the safety information at the beginning

of this section.

2 - Set the thermostat to the lowest setting.

3 - Turn o all electrical power to the unit.

4 - This furnace is equipped with an ignition device

which automatically lights the burners. Do not try to

light the burners by hand.

5 - Remove the upper access panel.

6 - Move gas valve switch to OFF position. Do not

force. See gure 19.

7 - Wait ve minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier

from a neighbor’s phone. Follow the gas supplier’s

instructions. If you do not smell gas go to next step.

8 - Move gas valve switch to ON position. Do not force.

See gure 19.

9 - Replace the upper access panel.

10 - Turn on all electrical power to to the unit.

11 - Set the thermostat to desired setting.

NOTE - When unit is initially started, steps 1 through

11 may need to be repeated to purge air from gas

line.

12 - If the appliance will not operate, follow the

instructions “Turning O Gas to Unit” and call the

gas supplier.

Turning O Gas to Unit

1 - Set the thermostat to the lowest setting.

2 - Turn o all electrical power to the unit if service is to

be performed.

3 - Remove the upper access panel.

4 - Move gas valve switch to OFF position. Do not

force. See gure 19.

5 - Replace the upper access panel.

B- Safety or Emergency Shutdown

Disconnect main power to unit. Close manual and main

gas valves.

C- Extended Period Shutdown

Turn o thermostat or set to “UNOCCUPIED” mode. Close

all gas valves (both internal and external to unit) to guar-

antee no gas leaks into combustion chamber. Turn o

power to unit. All access panels and covers must be in

place and secured.

IV-HEATING SYSTEM SERVICE CHECKS

A- C.S.A. Certication

All units are C.S.A. design certied without modications.

Refer to the ML180UHE(X) Installation Instruction.

B- Gas Piping

Gas supply piping should not allow more than 0.5”W.C.

drop in pressure between gas meter and unit. Supply gas

pipe must not be smaller than unit gas connection. Com-

pounds used on gas piping threaded joints should be re-

sistant to action of liqueed petroleum gases.

C- Testing Gas Piping

CAUTION

If a exible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outside

the furnace cabinet.

IMPORTANT

In case emergency shutdown is required, turn o the

main shut-o valve and disconnect the main power

to unit. These controls should be properly labeled

by the installer.

WARNING

Do not exceed 600 in-lbs (50 ft-lbs) torque when

attaching the gas piping to the gas valve.

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged if

subjected to more than 0.5psig (14” W.C.). See gure 20.

If the pressure is equal to or less than 0.5psig (14”W.C.),

close the manual shut-o valve before pressure testing to

isolate furnace from gas supply.

Loading...

Loading...