VANE PUMP > INSPECTION

for Preparation Click here

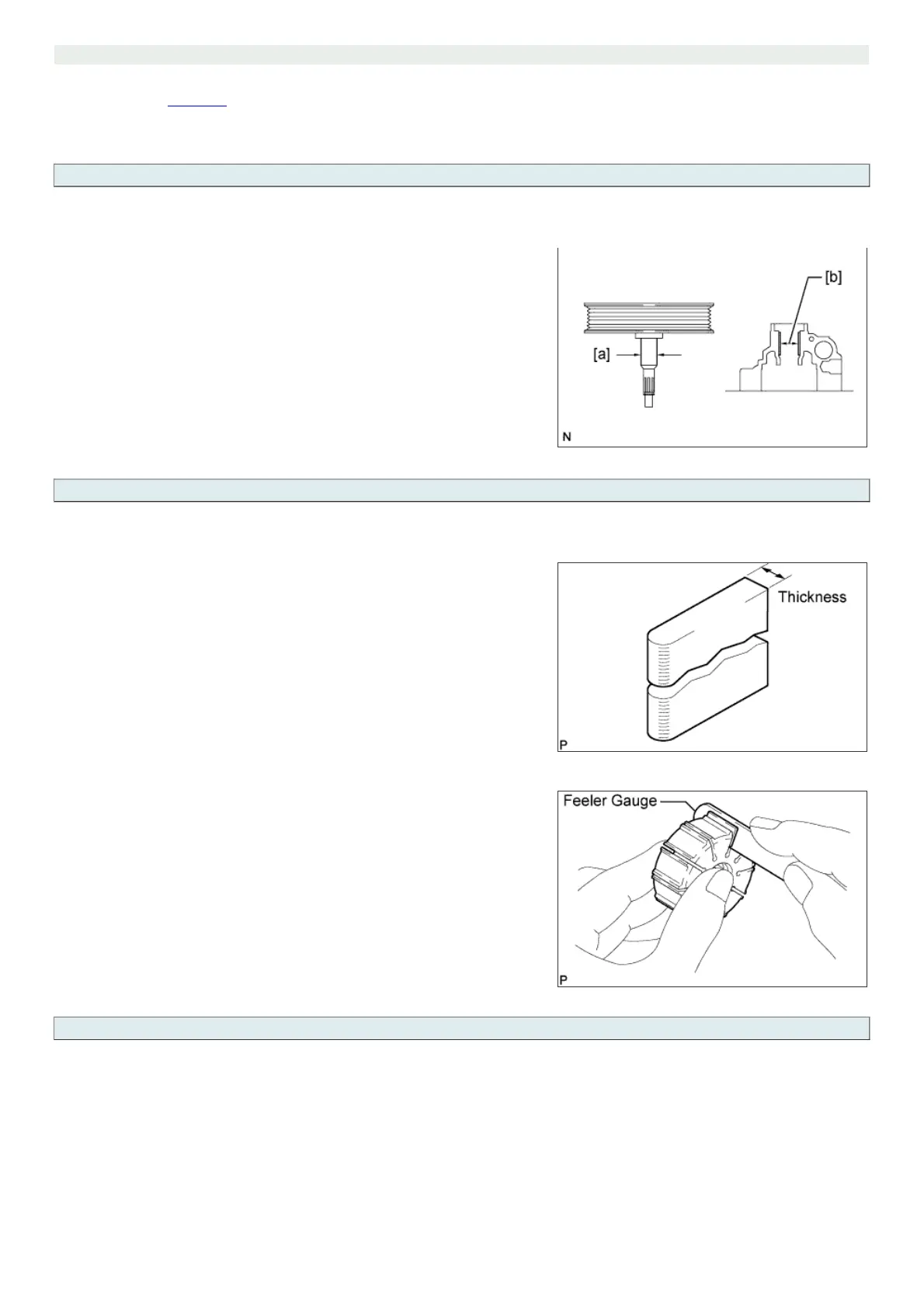

1. INSPECT VANE PUMP SHAFT AND BUSH IN VANE PUMP FRONT HOUSING

a. Using a micrometer, measure the outer diameter [a] of the vane pump shaft.

b. Using a vernier caliper, measure the inner diameter [b] of the vane pump front

housing bush.

c. Calculate the oil clearance.

Oil clearance = Inner diameter of the bush [b] - Outer diameter of the shaft [a]

Maximum oil clearance:

0.07 mm (0.00276 in.)

If the oil clearance is more than the maximum, replace the vane pump assembly.

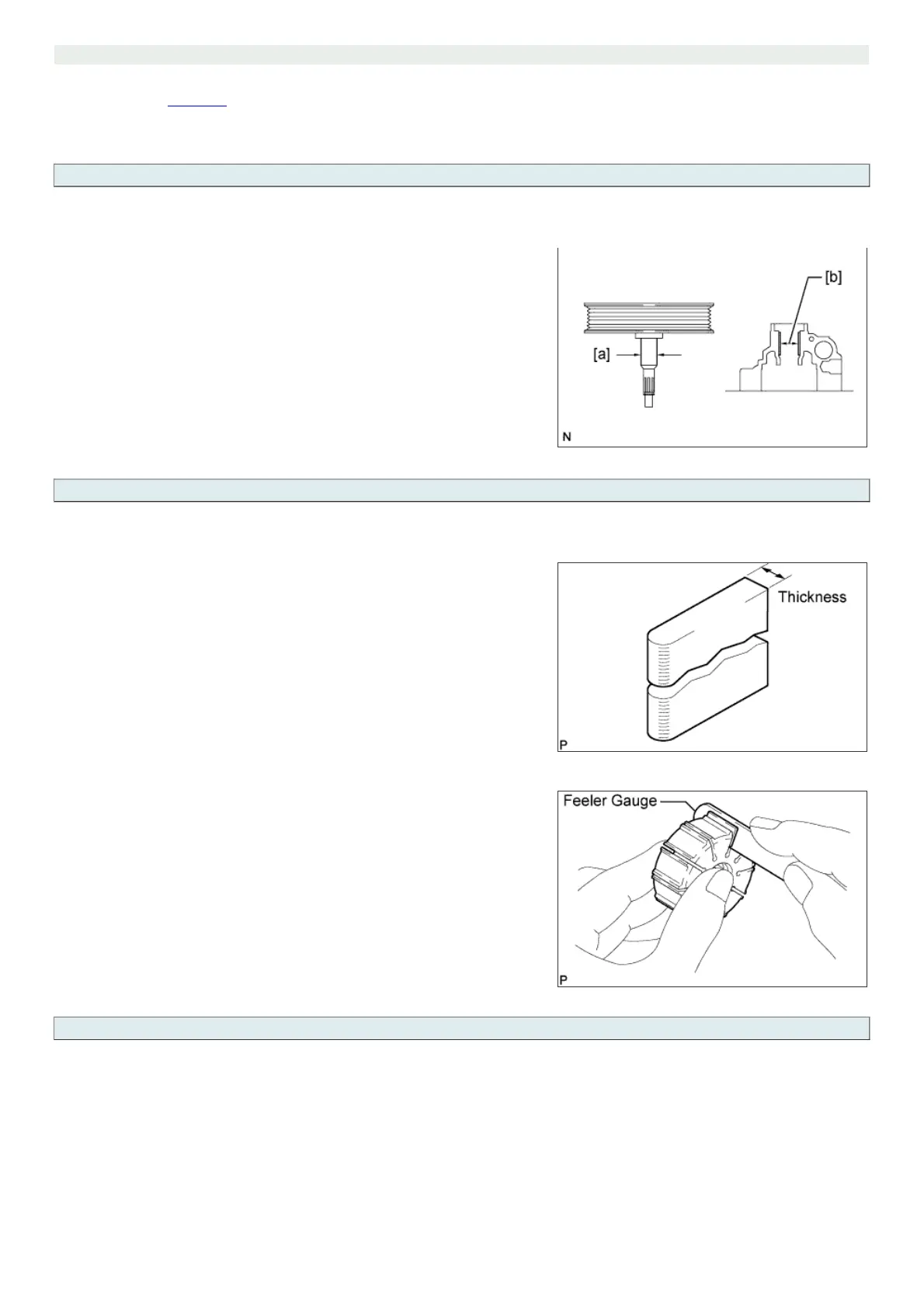

2. INSPECT VANE PUMP ROTOR AND VANE PUMP PLATE

a. Using a micrometer, measure the thickness of the vane pump plates.

Standard thickness:

1.405 to 1.411 mm (0.0553 to 0.0556 in.)

If the thickness is not as specified, replace the vane pump assembly.

b. Using a feeler gauge, measure the clearance between the side face of the vane

pump rotor groove and the vane pump plate.

Maximum clearance:

0.03 mm (0.00118 in.)

If the clearance is more than the maximum, replace the vane pump assembly.

3. INSPECT FLOW CONTROL VALVE ASSEMBLY

a. Coat the flow control valve with power steering fluid and check that it falls

smoothly into the valve hole by its own weight.

If the control valve does not fall into the hole smoothly, replace the vane pump

assembly.

Loading...

Loading...