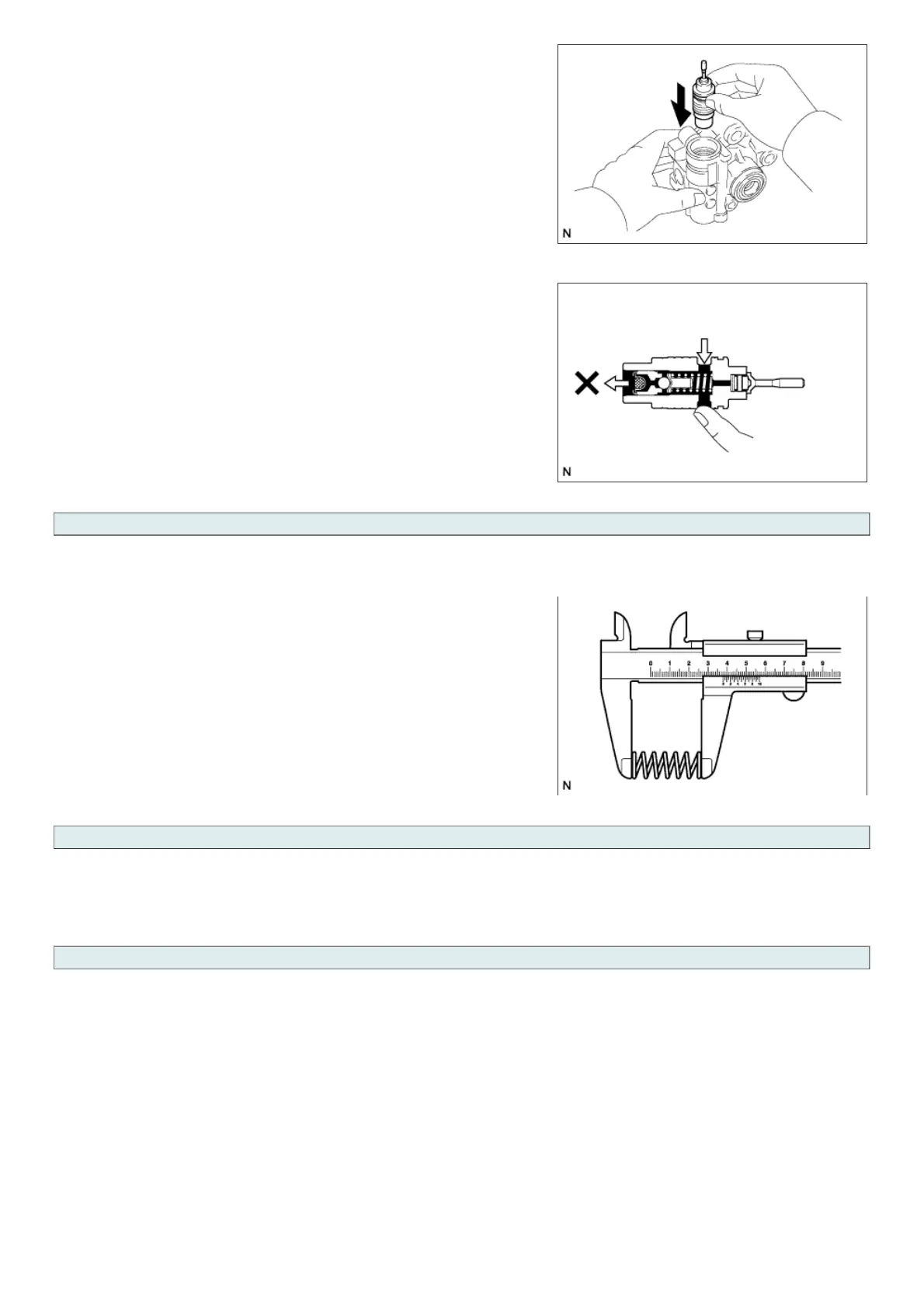

b. Check the flow control valve for leakage. Close one of the holes and apply 392

to 490 kPa (4.0 to 5.0 kgf/cm

2

, 57 to 71 psi) of compressed air into the opposite

side hole, and confirm that air does not come out from the end hole.

If air leaks, replace the vane pump assembly.

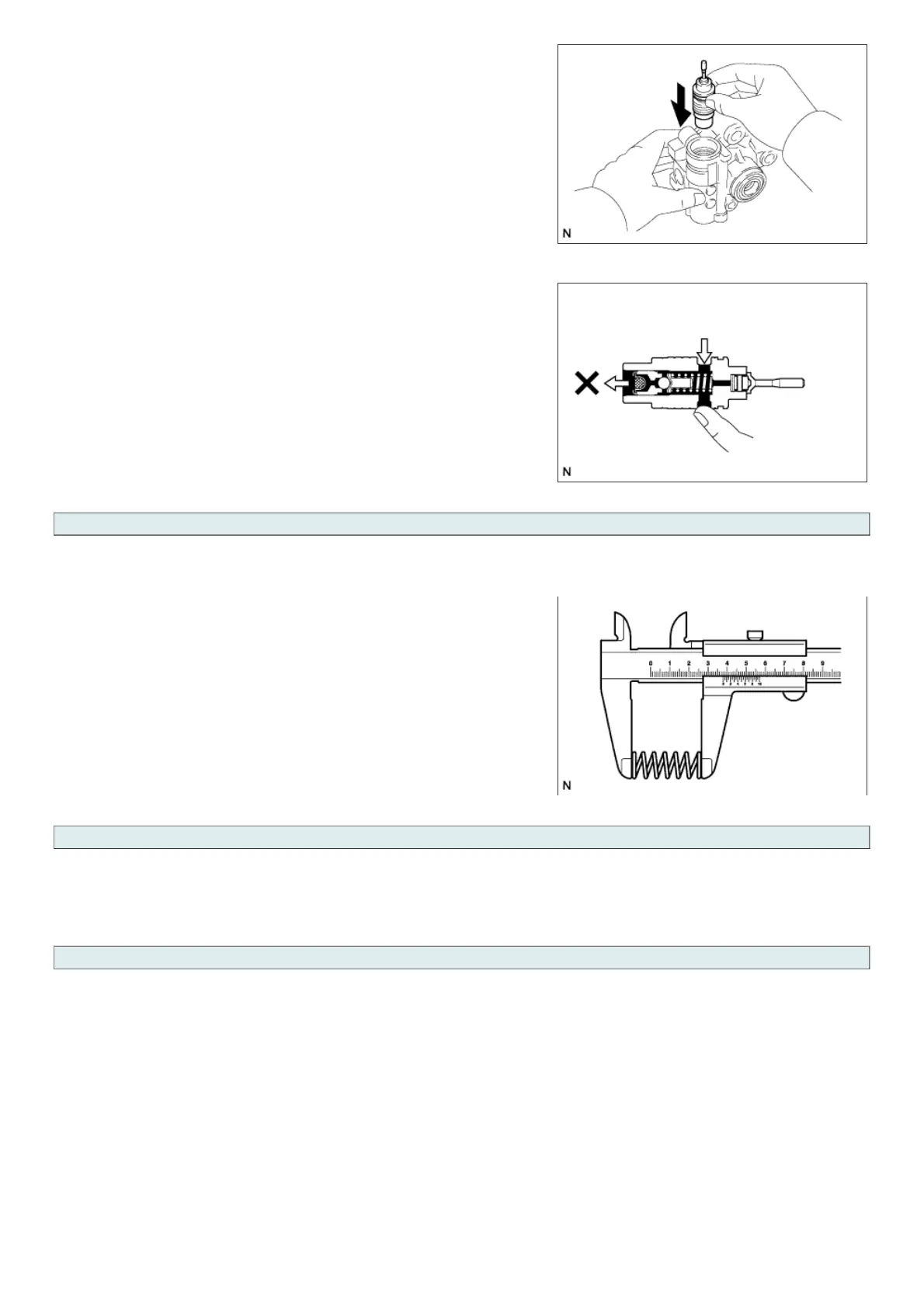

4. INSPECT FLOW CONTROL VALVE COMPRESSION SPRING

a. Using a vernier caliper, measure the free length of the compression spring.

Minimum free length:

31.3 mm (1.23 in.)

If the length is less than the minimum, replace the vane pump assembly.

5. INSPECT PRESSURE PORT UNION

a. Visually check the pressure port union for fluid leaks.

If there is a leak, replace the vane pump assembly.

6. INSPECT TOTAL PRELOAD

a. Check that the pump rotates smoothly without abnormal noise.

b. Temporarily install a service bolt.

Recommended service bolt:

Thread diameter:

10 mm (0.394 in.)

Thread pitch:

1.25 mm (0.0492 in.)

Bolt length:

50 mm (1.97 in.)

c. Using a torque wrench, measure the pump rotating torque.

Standard rotating torque:

Loading...

Loading...