Operation

18

GA 03.108/14.02 - 01/03

4.3 Shutdown and Storage

We recommend to keep the RUVAC WS

with a PFPE filling running even during pro-

longed intervals (e. g. over night) with the

intake line closed. This can help to avoid

corrosion during standstill.

Close the valve between the Roots pump and the vacu-

um system. First switch off the Roots

pump, then the backing pump.

After working with corrosive gases, the system should be

vented with dry protective gas (e.g. N

2

) to prevent corro-

sion during standstill.

When shutting down the pump and removing it from the

system, it is advisable to seal the connecting flanges

tightly.

Before removing pump from the vacuum

system, disconnect it from the mains supp-

ly.

Before removing the RUVAC WS PFPE from the system

it must be purged with nitrogen and sealed in a gas-tight

manner.

For transportation and storing of the pump, observe the

information provided in Section 2.

4.4 Changing from Vertical

to Horizontal Flow

The RUVAC WS/WSUs are supplied as standard for ver-

tical flow unless you specifically request horizontal flow.

Moreover, the pump may be converted from one flow

direction to the other.

For this proceed as follows:

Drain the lubricant (11/2) or (11/4) and tightly screw the

oil-drain plug back in. Remove the feet, turn the pump by

90° as shown in Fig. 5 (dimensional drawing) and mount

the feet for the new direction of flow.

The longitudinal axis of the pump must

remain horizontal so that no residual lubri-

cant can flow from the side chambers into

the pumping chamber.

Fill in lubricant (11/3); (see Section 3.2).

If a pressure switch has been installed, turn it so that it

again points vertically upwards.

The valve in the pressure balance line of the RUVAC

WSU is designed to work with both vertical and horizon-

tal flow of the pump.

Caution

Warning

Caution

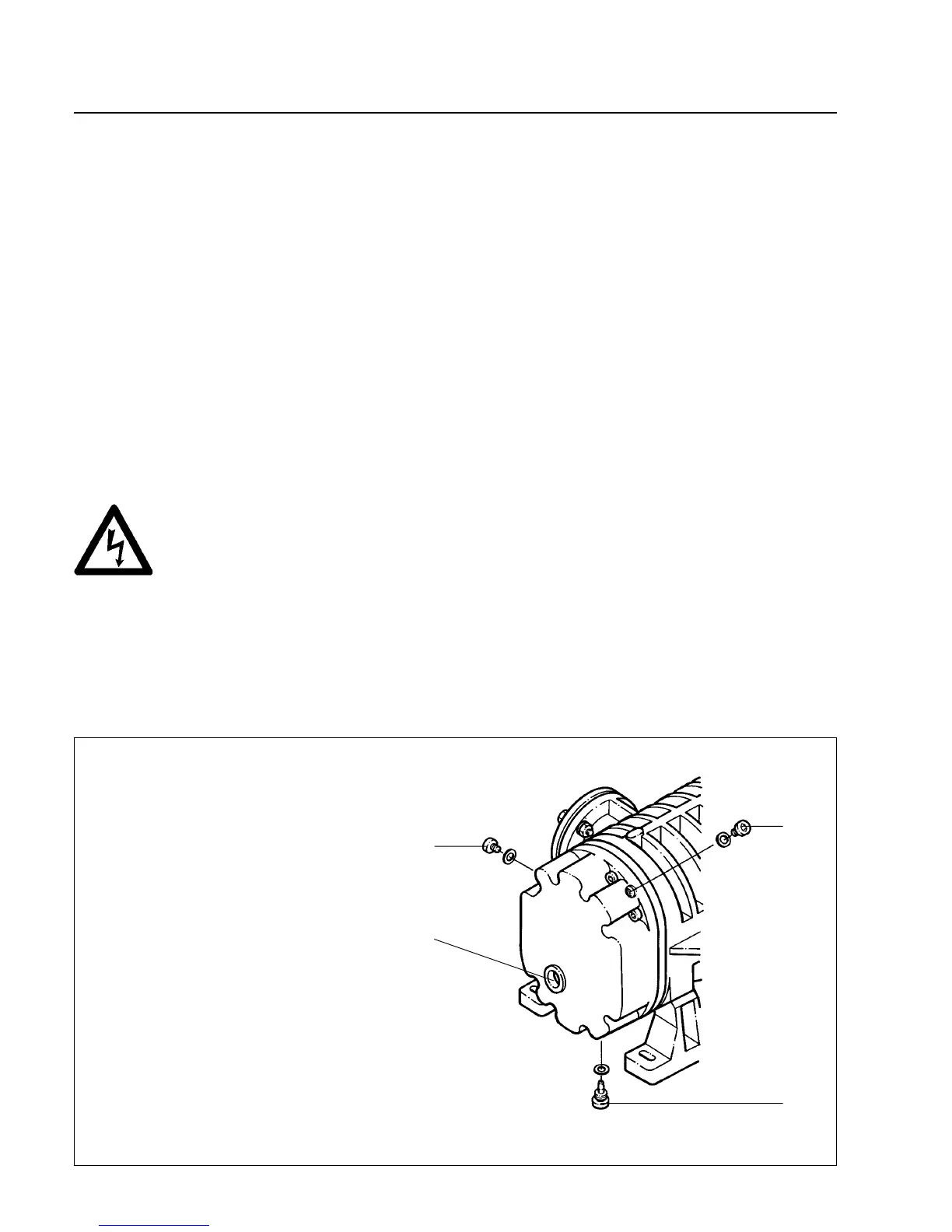

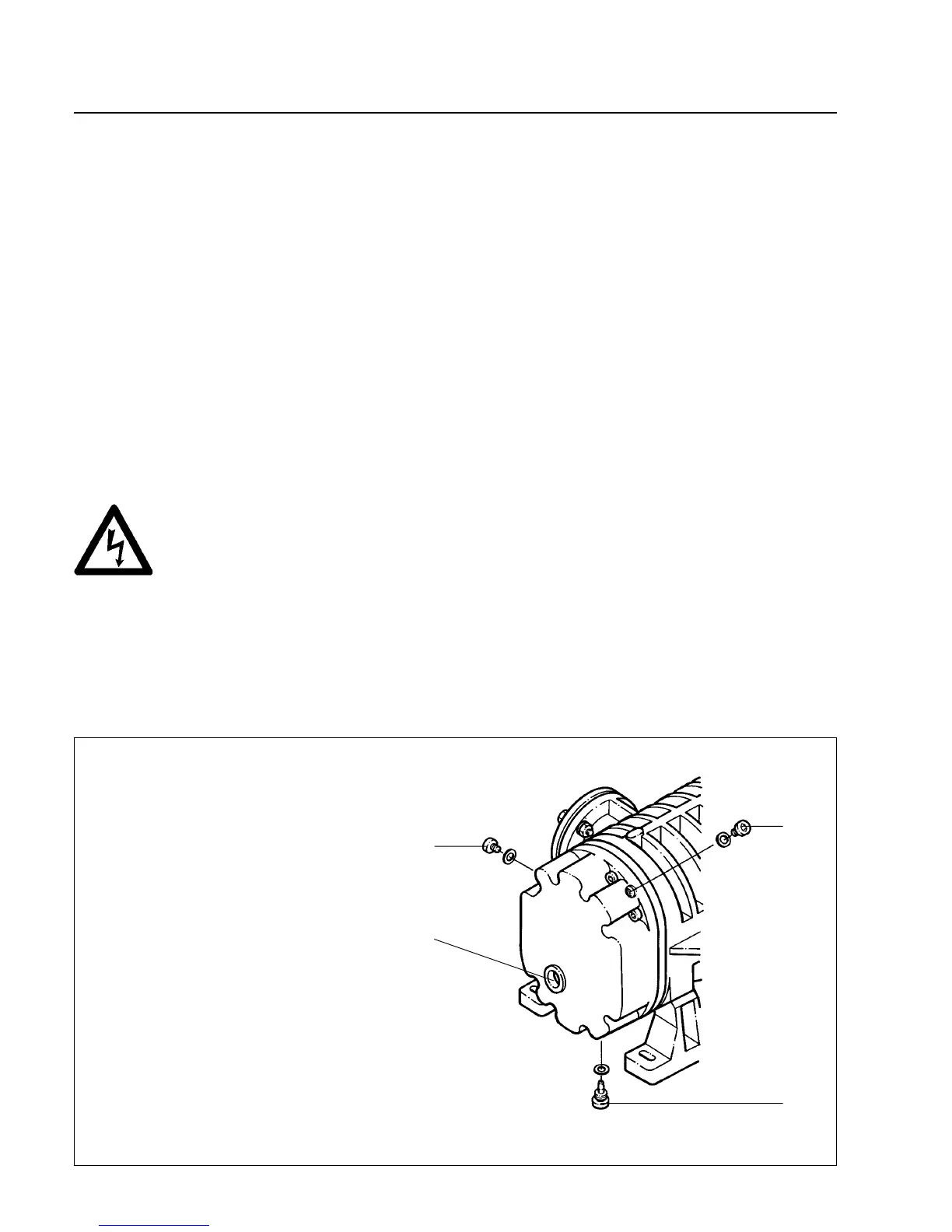

Fig. 11 Changing the lubricant

Key to Fig. 11

1 Oil-level glass

2 Oil-drain plug for vertical flow

3 Oil-fill plug

4 Magnetic oil-drain plug for horizontal flow

1

2

3

4

Loading...

Loading...