10

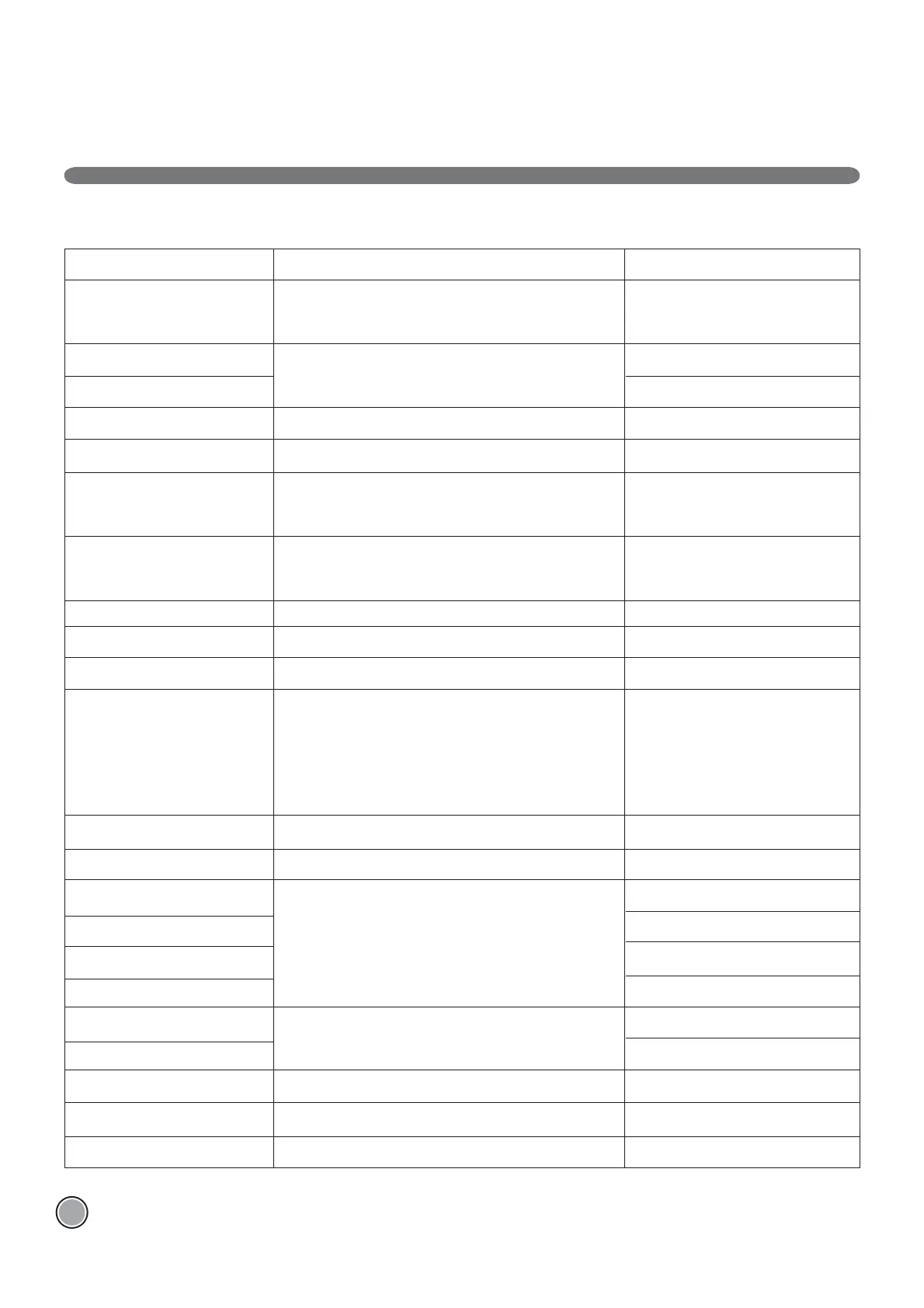

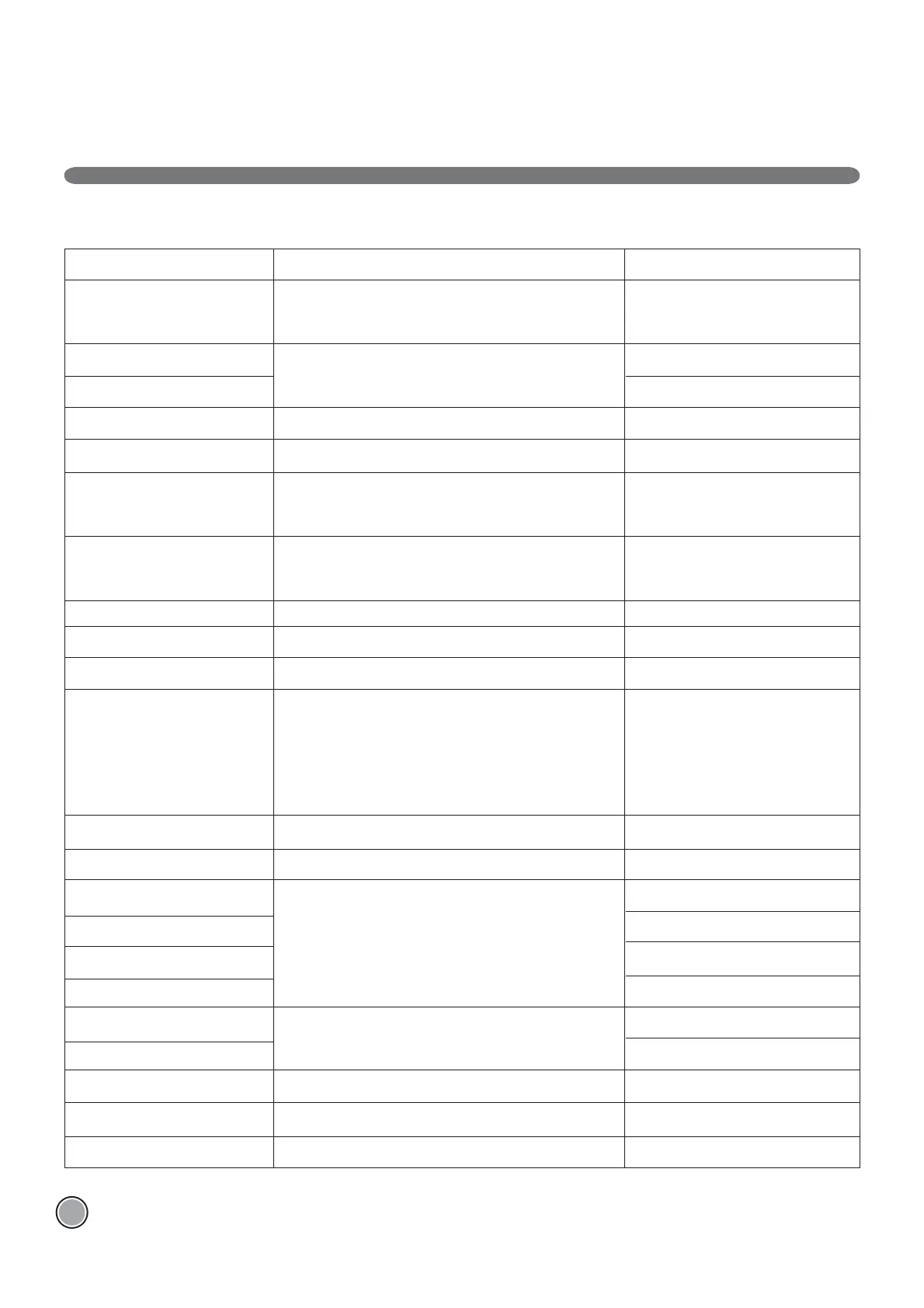

PARTS SPECIFICATIONS

Suction Motor Maker: STANDARD

ITEMS

1.0 STANDARD OPERATING

CONDITION

1.1 RATED VOLTAGE

1.2

OPERATING VOLTAGE RANGE

1.3 RATED LOAD

1.4

DIRECTION OF ROTATION

1.5 OPERATING TEMP, HU-

MID, RANGE

1.6 STORAGE TEMP, HUMID,

RANGE

2.0 TESTING CONDITION

2.1 POWER SUPPLY

2.2

MOTOR MOUNTING POSOTION

2.3

TEMPERATURE/HUMIDITY

2.4

DIRECTION OF ROTATION

3.0

ELECTRICAL CHARACTERISTICS

3.1 NO LOAD CURRENT

3.2 NO LOAD SPEED

3.3

RATED LOAD CURRENT

3.4 RATED LOAD SPEED

3.5 STALL CURRENT

3.6 STALL TORQUE

3.7

INSULATION RESISTANCE

3.8 DIELECTRIC STRENGTH

3.9

PERFORMANCE CURVE

SPECIFICATIONS

12.0 V

8.0 V ~ 24.0 V

5.0 mN.m ᴾ@51 gf.cm

CCW & CW

-10 ᴱ@@75 ᴱ

5 %RH ~ 95 %RH

-10 ᴱ@@75 ᴱ

5 %RH ~ 95 %RH

DC onstant power supply

Shaft output side wl any direction

10 ᴱ@@30 ᴱ

30 %RH ~ 95 %RH

Refer to JIS standard (20 ᴱᴦ2

ᴱ,65%ᴦ5%) in case of problems

CCW

200 mA (max.)

9600 rpm ᴦ@10% rpm

800 mA (max.)

8500 rpm ᴦ@10% rpm

6.0 A (max.)

35.0 mN.m (min.)

10 MΩ 500 VDC 1 minute

10 mA 250 VAC 1 second

RS385-ST-2265

CONDITIONS

DC constant power supply between motor terminal

Pulley load

View point: Shaft output direction

View point: Shaft output direction

General

30~60 sec run-in period before

measurement taken

Based on measurement at two different load

( 7.35mN.m & 21mN.m)

Applied between motor housing and terminal without failure

Between motor terminal and motor metal housing

Loading...

Loading...