Assembly

In order to fulfil the requirements for air-tightness class D, the devices must be installed as per ‘Assembly Instruction

Lindab Safe’.

FMDRU must be installed with the air flow in the direction of the arrow.

The devices allow 100 mm duct insulation without sticker or measuring points being hidden. The cup around FMDRU’s

damper knob allows 50 mm duct insulation without the knob being hidden. For 100 mm insulation, an insulation cup, IK,

is available.

For optimum readability (regardless of the installation position), the plate with the sticker can be turned, folded up to

prevent it disappearing in any insulation or to be easily removed and positioned separately from the device.

Measurement

By measuring the pressure difference ∆p in Pa at the measuring points, you can achieve a flow q in l/s using the equa-

tion on the devices.

With FMDRU you can set the desired flow, as the damper blade is adjustable through 0–90° (0°=fully open, 90°=com-

pletely closed) using the knob in the cup. Locking is performed using screws for Pozidrive (PZD2) and the damper angle

can be read off a stamped grade on the edge of the cup.

The specified flows only apply for air with a density of 1.2 kg/m

3

. For air of another density (r

other

) the flow (q

other_density

)

is achieved as per the formula:

q

other_density

= q

equation

×

ρ

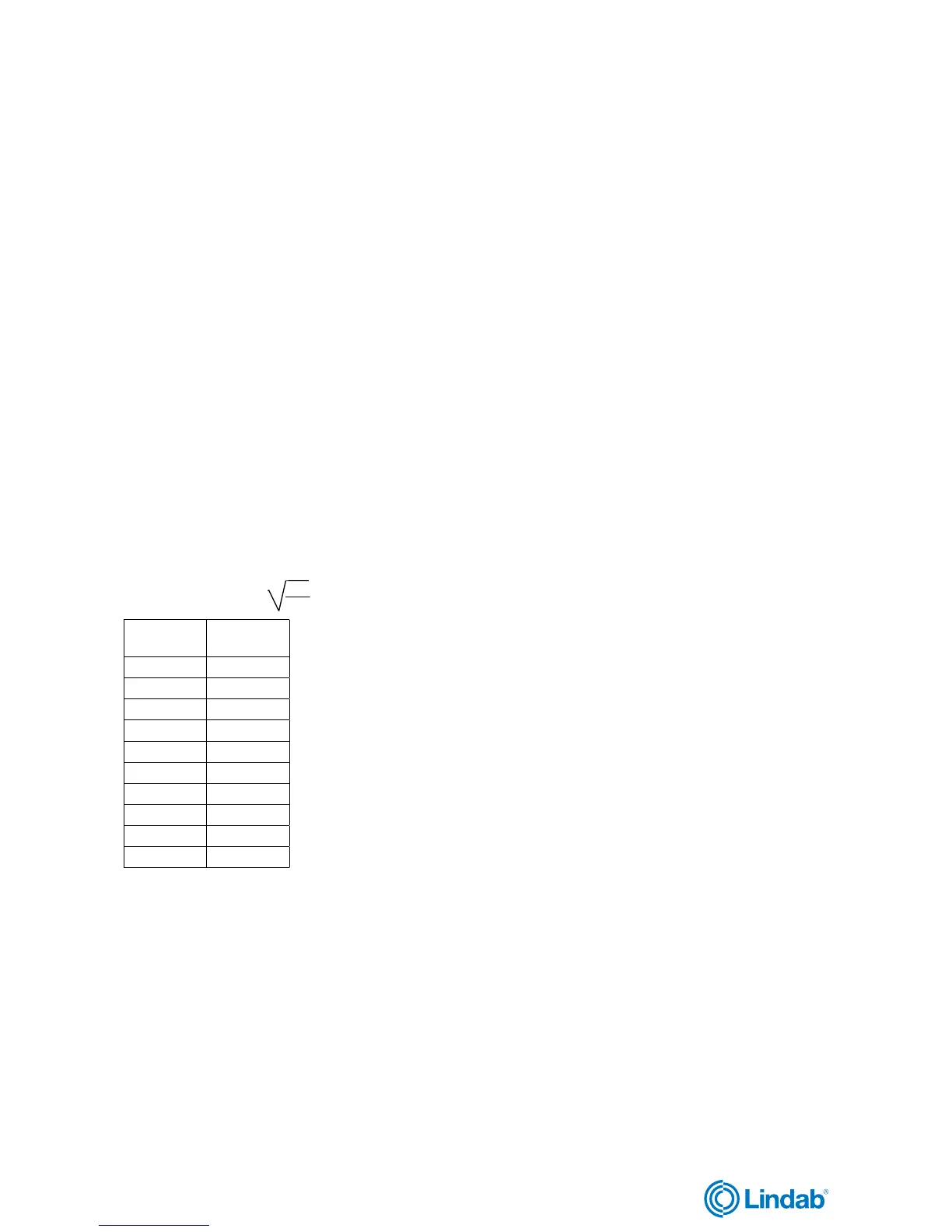

Dimension

mm

k-factor

80– 63 4,40

100– 80 7,32

125–100 11,2

160–125 18,0

200–160 29,4

250–200 45,7

315 –250 73,3

400–315 116

500–400 191

630–500 283

Systematic error

Straight stretches are required in order to achieve flows as per equations with specified accuracy. The systematic error

m

2

is 5% and 10% below the minimum requirements for straight stretches as specified. For these minimum straight

requirements – do not install measuring points in line with the nearest bend’s inside radius.

Maintenance

The devices normally don't require any maintenance.

Cleaning

FMU does not limit cleaning opportunities.

Flow meters

FMU, FMDRU

Loading...

Loading...