05-3044-A

6

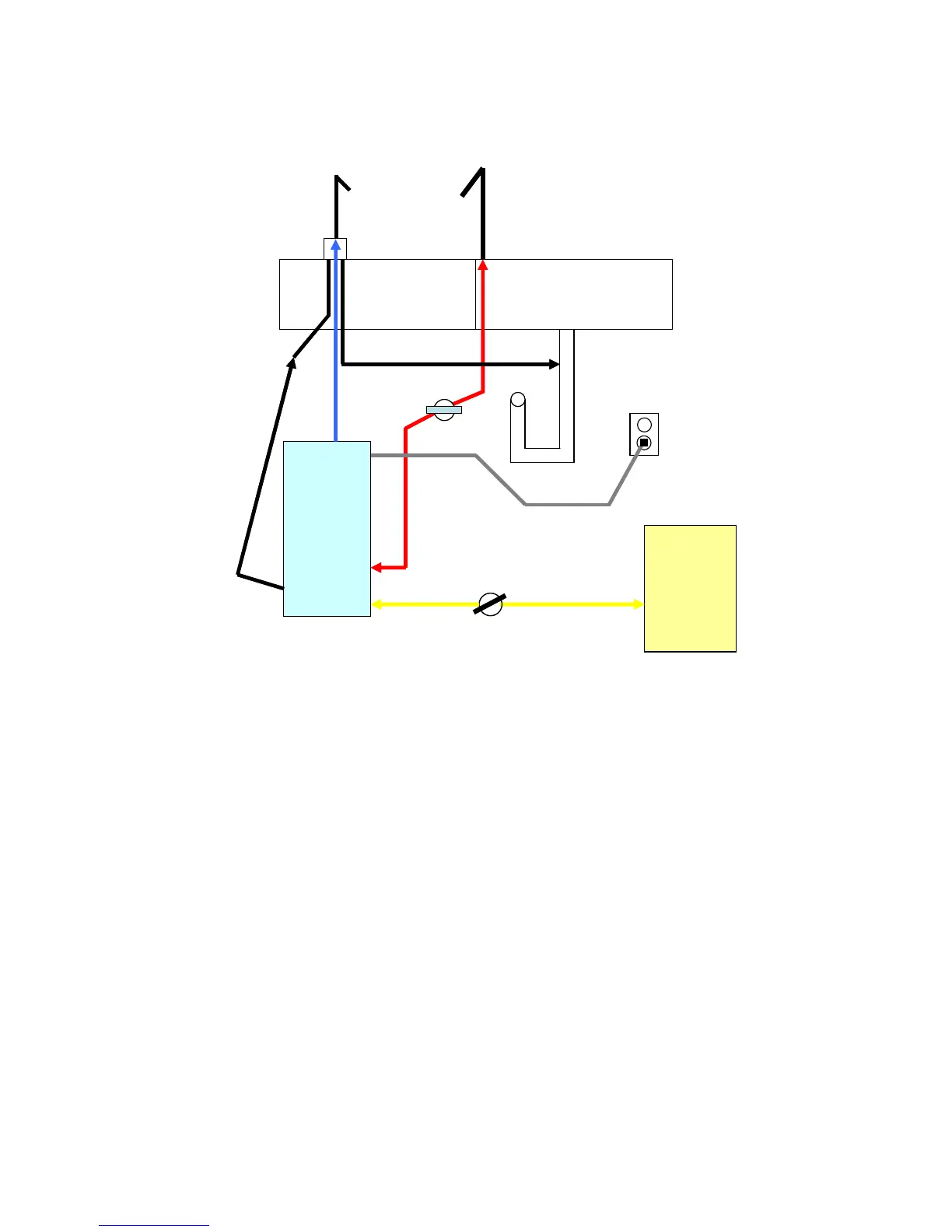

LINX 160 Drinking Water System Installation Diagram

Section 4. Operation

The LINX 160 system operations are automatic. The system employs two flow sensors to measure and control product and waste

water volumes and to indicate when it is time to replace filters and/or cartridges. The user only has to open and close the

faucet to operate the systems.

Input Voltage Selection (120VAC or 240VAC)

As received, the LINX 160 system is ready for operation on 100-120VAC input power. For operation on 200-240VAC input

power, your Authorized Dealer needs to remove the top enclosure and replace the “120VAC” connector with the “240VAC”

connector in the “Voltage Selection” receptacle on the side of the power supply. These two connectors are tethered together.

Selecting Feed Water TDS Level

The LINX 160 system must be set to your incoming feed water quality. Two settings are available: a first level for 0-500 ppm,

and a second level for 501-1000 ppm TDS feed waters. The factory setting is for ≤500 ppm TDS feed water which provides 1.5

gallons (6.0 liters) of drinking water prior to regeneration, yielding 70% water recovery. Selecting the 501-1000 ppm TDS feed

level provides 1.0 gallons (4.0 liters) of drinking water with 61% recovery. Your Authorized Dealer will determine the TDS of

your feed water as part of the installation.

LINX 160

System

Waste to

air gap

Product

water

Dedicated

LINX 160 system

faucet

Faucet

air gap

Cold feed

water

Feed water to

LINX 160

system via

T-fitting at cold

feed valve

Drain

with

P-trap

Waste to drain above P-trap

Power Cord to

LINX 160 system

Tank

valve

Main Sink

Faucet

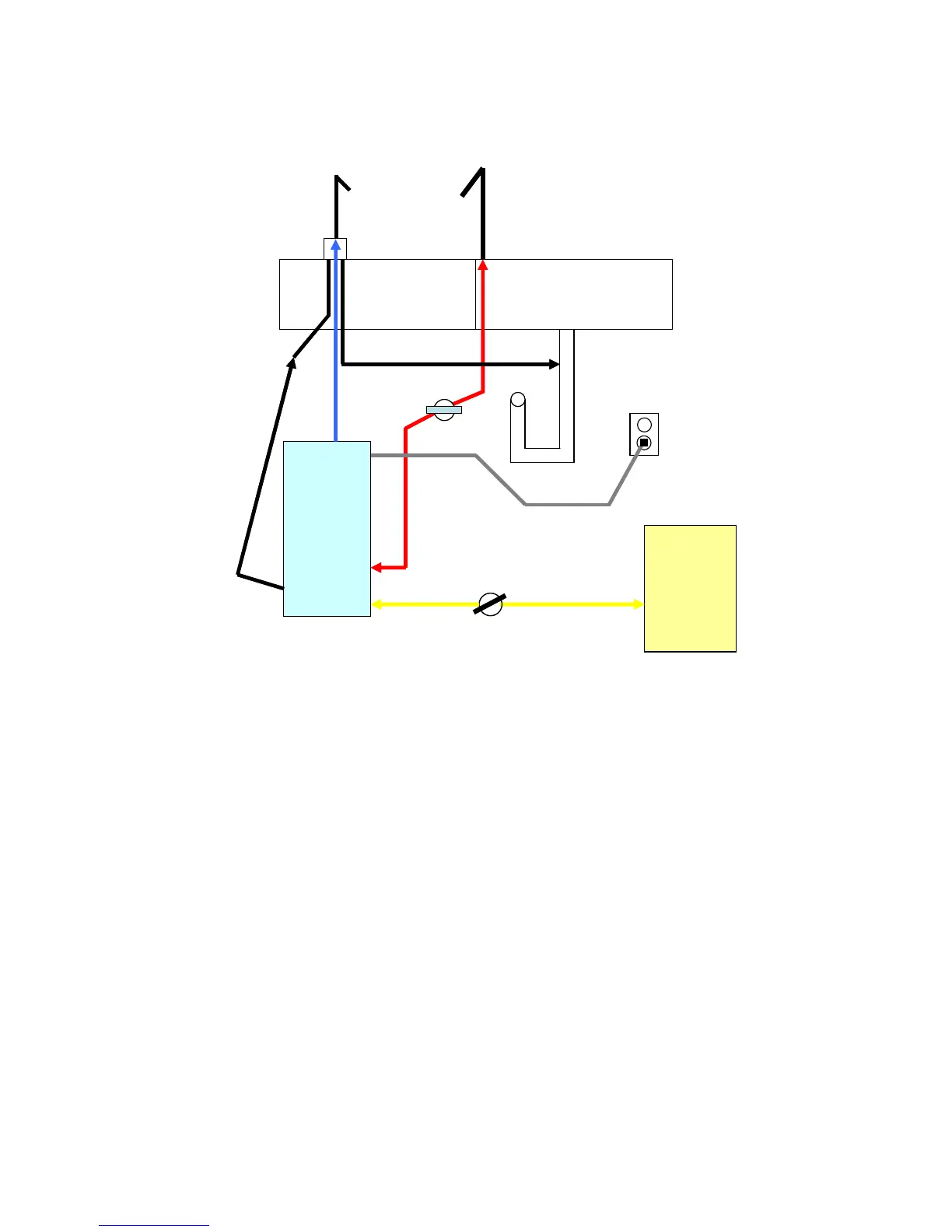

LINX 160

System

Waste to

air gap

Product

water

Dedicated

LINX 160 system

faucet

Faucet

air gap

Cold feed

water

Feed water to

LINX 160

system via

T-fitting at cold

feed valve

Drain

with

P-trap

Waste to drain above P-trap

Power Cord to

LINX 160 system

Tank

valve

Main Sink

Faucet

Loading...

Loading...