The

lifter

can operate in either of the

two

following

ways:

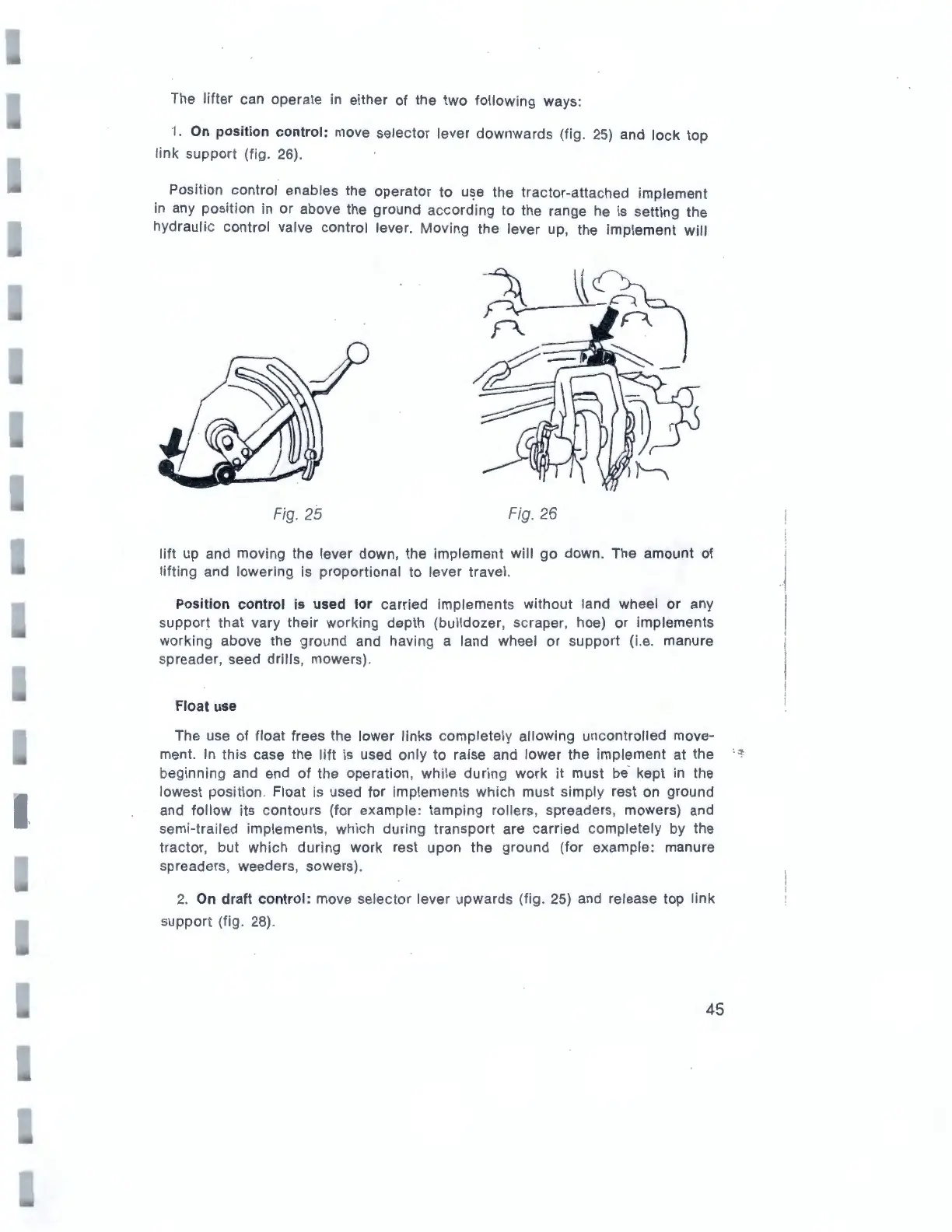

1.

On

position control: move

selector

lever

downwards

(fig.

25)

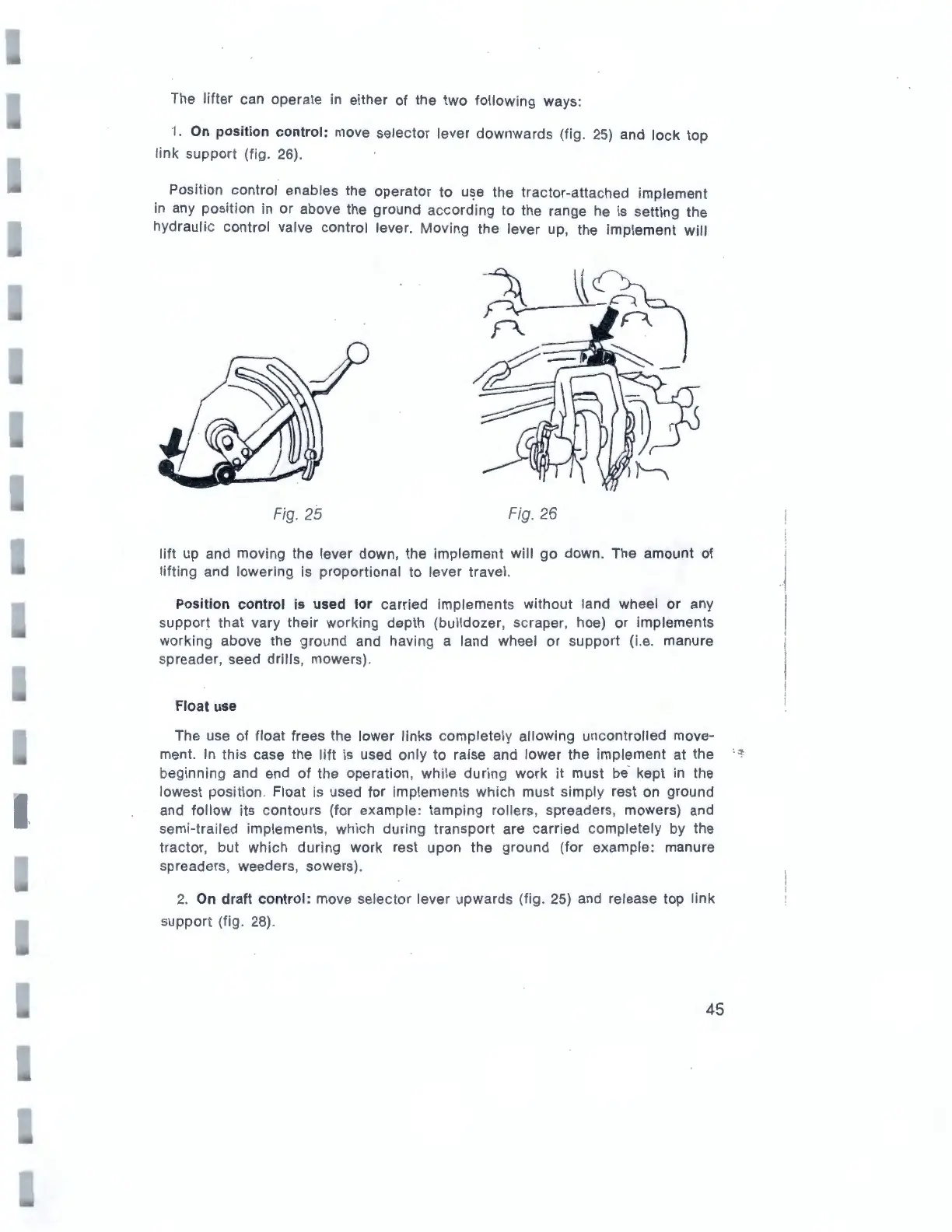

and

lock

top

link

support

(fig. 26).

Position control enables the

operator

to

u~e

the tractor-attached

implement

in any

posit

ion in

or

above the

ground

according

to the range

he

is setting the

hydraulic

control valve

control

lever. Moving the lever up, the

imple

ment

will

F

ig.

25 F

ig.

26

lift up and moving the lever down, the i

mplement

will go down. The amount of

lifting and

lowering

is

proportional

to lever travel.

Position control

is

used for carried implements

without

land wheel

or

any

support

that vary

their

working

depth (bulldozer, scraper, hoe)

or

implements

working

above the ground and havi

ng

a land wheel or

support

(i.e. manure

spreader, seed

drills

, mowers).

Float use

The use of

float

frees the

lower

links

completely

allowing

uncontrolled

move-

ment. In this case the lift is used

only

to raise and

lower

the

implement

at the

'~

beginning and end of the operation, while

during

work

it must be kept in the

lowest position. Float is used

for

implements

which

must simply rest

on

ground

and

follow

its

contours

(

for

example:

tamping

rollers, spreaders, mowers) and

semi-trailed

implements

, wh ich

during

transport

are carried

completely

by the

tractor

, but

which

during

work

rest upon the ground (for example: manure

spreaders, weeders, sowers).

2.

On

draft control: move selector lever

upwards

(fig. 25) and release top

link

su

pport

(fig. 28).

45

i

.j

Loading...

Loading...