58

14

14

14

14 ) Gear

Gear

Gear

Gear rack

rack

rack

rack inspection

inspection

inspection

inspection

Inspect the mounting bolts of gear rack are

loose, tighten it if necessary.

15

15

15

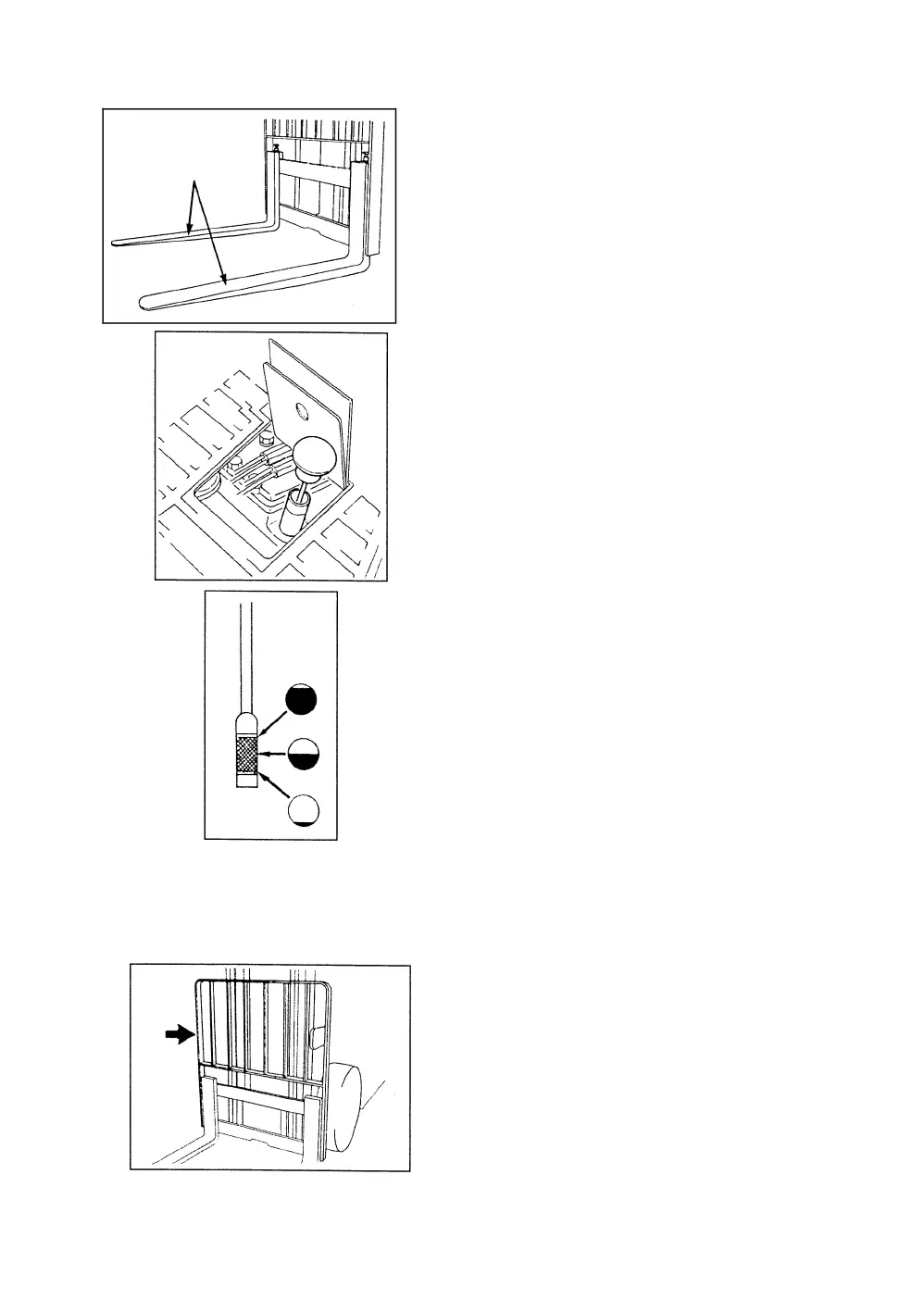

15 ) Fork

Fork

Fork

Fork and

and

and

and fork

fork

fork

fork loaction

loaction

loaction

loaction pin

pin

pin

pin

Check the mounting condition of location

pin and whether the fork is deformed or

cracked.

16

16

16

16 ) Front

Front

Front

Front headlamp

headlamp

headlamp

headlamp and

and

and

and front

front

front

front

combination

combination

combination

combination lamp

lamp

lamp

lamp

Inspect the lamp shade and the bulb are

clean and damaged.

17

17

17

17 ) seat

seat

seat

seat adjustment

adjustment

adjustment

adjustment

The seat should be arranged properly. If the

seat is not at the proper position,pull right

the adjustment handle. Adjust the seat to the

position where the hand and foot can easily

control. After adjustment, move the seat

forward and backward slightly. Make sure

the seat is locked reliably.

18

18

18

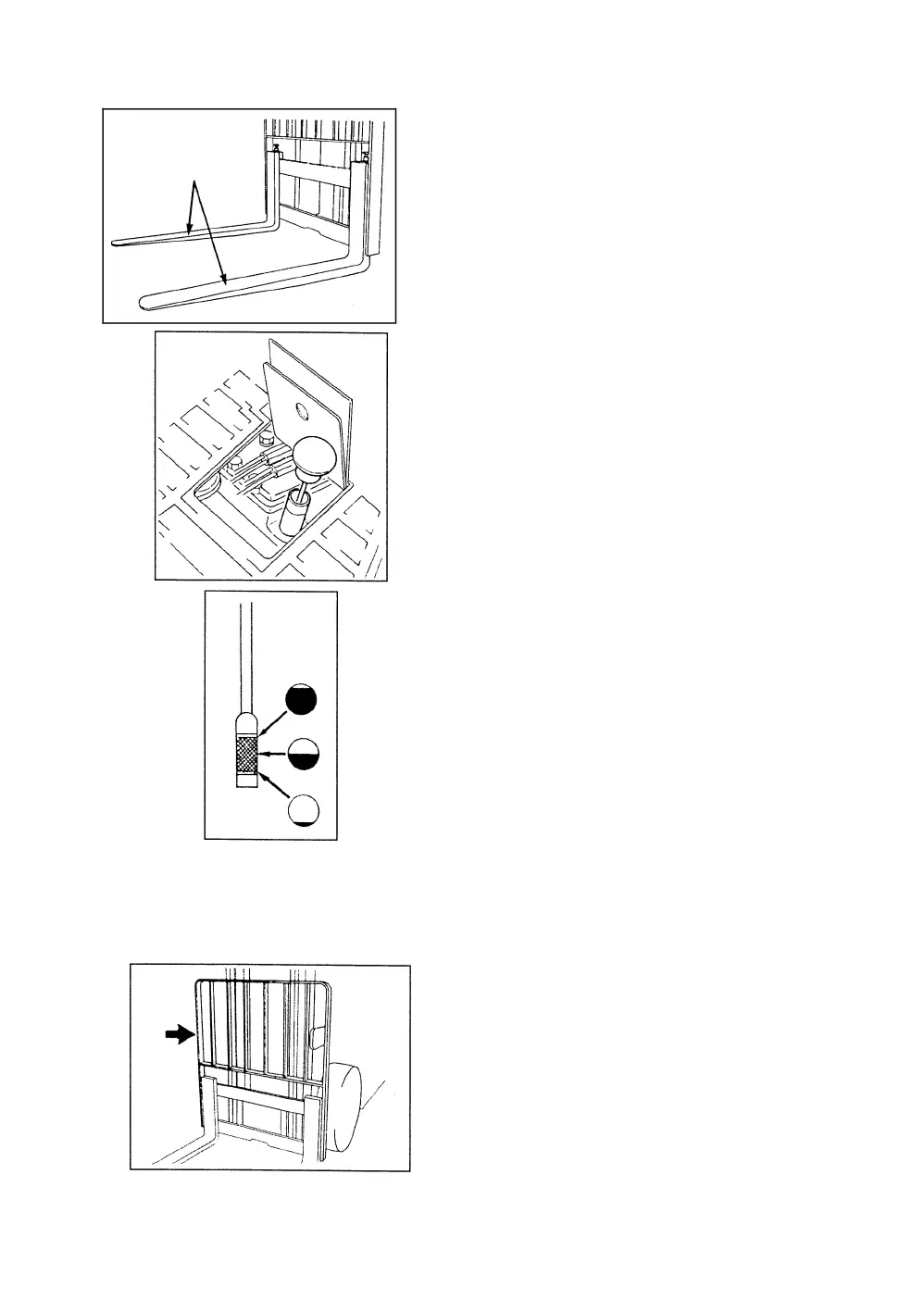

18 ) Shifting

Shifting

Shifting

Shifting lever

lever

lever

lever inspection

inspection

inspection

inspection

Inspect whether the shifting lever is loose

and the operation handle.

19

19

19

19 ) Control

Control

Control

Control lever

lever

lever

lever of

of

of

of the

the

the

the multi-way

multi-way

multi-way

multi-way valve

valve

valve

valve

Inspect whether the control lever (lift, tilt

and attachment) is loose and the operation is

easy.

20

20

20

20 ) Parking

Parking

Parking

Parking brake

brake

brake

brake inspection

inspection

inspection

inspection

Make sure that parking brake is safe and

reliable after pulling up the parking brake

lever.

Staring

Staring

Staring

Staring the

the

the

the engine

engine

engine

engine

Before the engine startup, make sure the

shifting lever is at the neutral, the parking

brake is reliable.

21

21

21

21 ) Instrument

Instrument

Instrument

Instrument

Timer, water temperature gauge and fuel

gauge can make the operator know the status

of the forklift operated.

Loading...

Loading...