VARI-FLOW PRESSURE CONTROLLER IO&M

B51004-002

2

LOW pressure port

HIGH pressure port

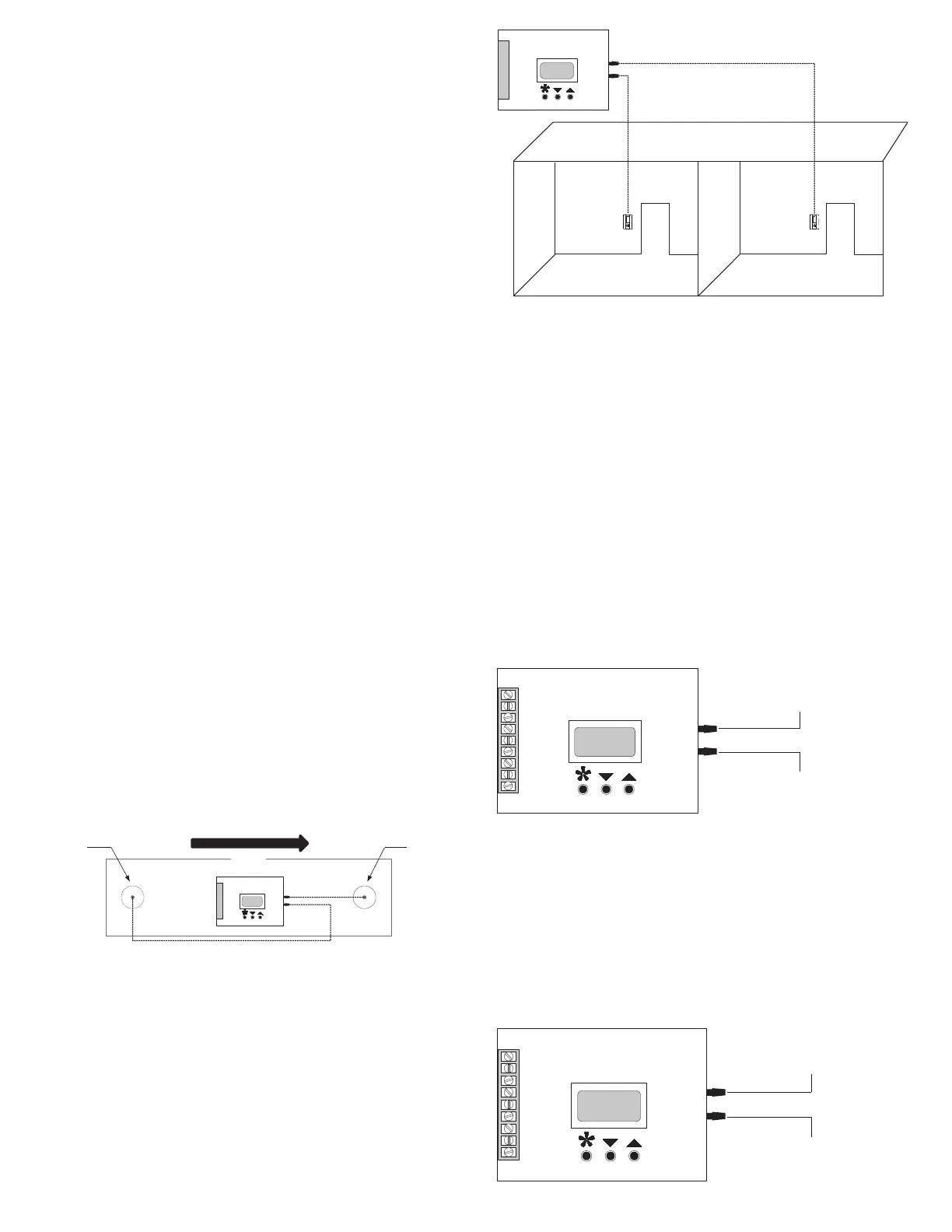

Static Pressure Control

• Place the Pressure Controller box as close as possible

to the pressure tap and fan. The location should be easy

to access.

• Keep the length of the wiring between control box and

the fan to 100 feet (30 m) or less.

• Keep the length of the pressure tubing between control

box and pressure taps to 50 feet (15 m) or less.

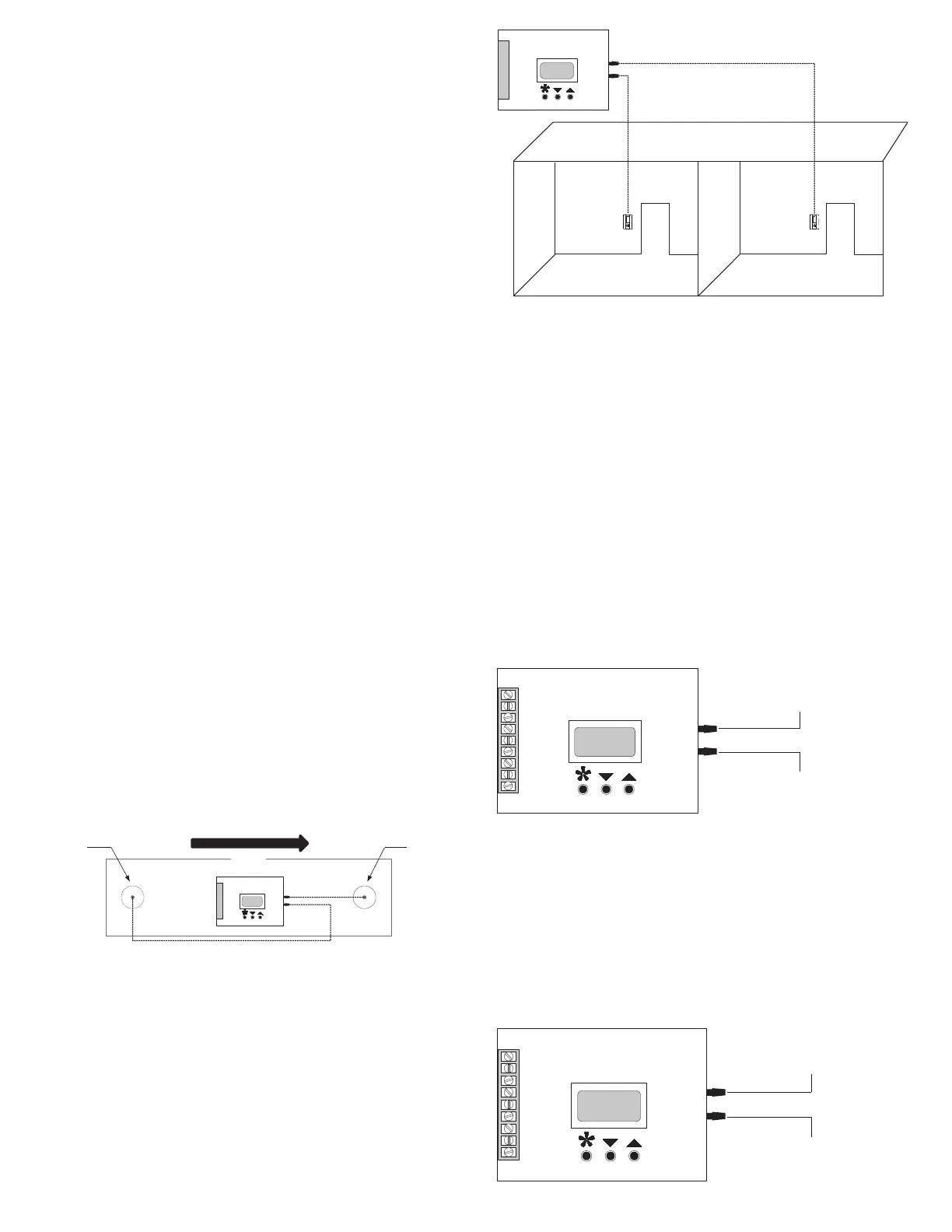

One Duct Tap

The One Duct Tap maintains a constant pressure in the

duct. The constant pressure is relative to ambient pressure of

space where the Pressure Controller is mounted. To connect

the One Duct Tap:

• Use a 1/8” (3.175 mm) tubing to connect between the

pressure tap and HIGH pressure port on the Pressure

Controller.

• Leave the LOW pressure port open to the atmosphere.

Com

24V~

Prs+

Rev

Dir

Ext

Kcom

Knc

Kno

Open to Atmosphere

Low Pressure Port

High Pressure Port

To Pressure Tap

1/8" (3.175 mm) Tubing

One Room Tap

The One Room Tap maintains a constant pressure in a

room. The constant pressure depends on the value of the

space pressure where the Pressure Controller is mounted.

To connect the One Room Tap:

• Use a 1/8” (3.175 mm) tubing to connect between the

pressure tap and HIGH pressure port on the Pressure

Controller.

• Leave the LOW pressure port open to the atmosphere.

Com

24V~

Prs+

Rev

Dir

Ext

Kcom

Knc

Kno

Open to Atmosphere

Low Pressure Port

High Pressure Port

To Pressure Tap

1/8" (3.175mm) Tubing

Duct Pressure

Location and Positioning

Obtaining optimum results from positioning the duct

pressure tap is dependent on the planning and layout of

the system.

• Install the pressure tap on a duct with a minimum of 1.5

duct diameters of straight duct. Place it away from any

damper, elbow, or other obstructions.

• Ensure that the pressure tap is placed toward the top of

a duct that runs horizontally. This minimizes condensa-

tion entering the tube.

• On a rectangular duct mount, place the pressure tap

away from the corners.

• On a stack system, place the pressure tap at a distance

of one-third from the bottom of the duct.

Installation

• Remove any exterior insulation. If required, insulation

could be replaced after the installation.

• Drill a 3/8” (9.525 mm) hole in the duct where the pres-

sure tap should be installed.

• Place the 6” (152 mm) tube into the hole and move the

mounting base up to the duct in any orientation.

• On a round duct, rotate the tap so that the mounting

holes are aligned with the duct.

• Attach the duct pressure tap to the duct using self-drill-

ing zip screws, tting in the gasket evenly.

• Attach the tubing from the barbed port to the pressure

controller.

Duct Velocity or Air Volume

Location and Positioning

Obtaining optimum results from positioning the pressure

taps is dependent on the planning and layout of the system.

• If you are using total and static probe to measure velocity

pressure, mount the pressure taps in close proximity to

each other but in such a way so as not to interfere with

each other. For this, select a spot in the duct that is at

least 5 duct diameters away from any obstructions such

as elbows, dampers, transitions, or diusers.

Static

Pressure Tap

Low Pressure Port

High Pressure Port

Duct

Total

Pressure Tap

Air Flow

Room Pressure

• Identify the area(s) in which you intend to control the

static pressure.

• Mount the pressure tap near the center of the zone that

you intend to measure.

• Do not mount the pressure tap in an enclosed area such

as a closet and areas that are prone to drafts.

Loading...

Loading...