3

VARI-FLOW PRESSURE CONTROLLER IO&M

B51004-002

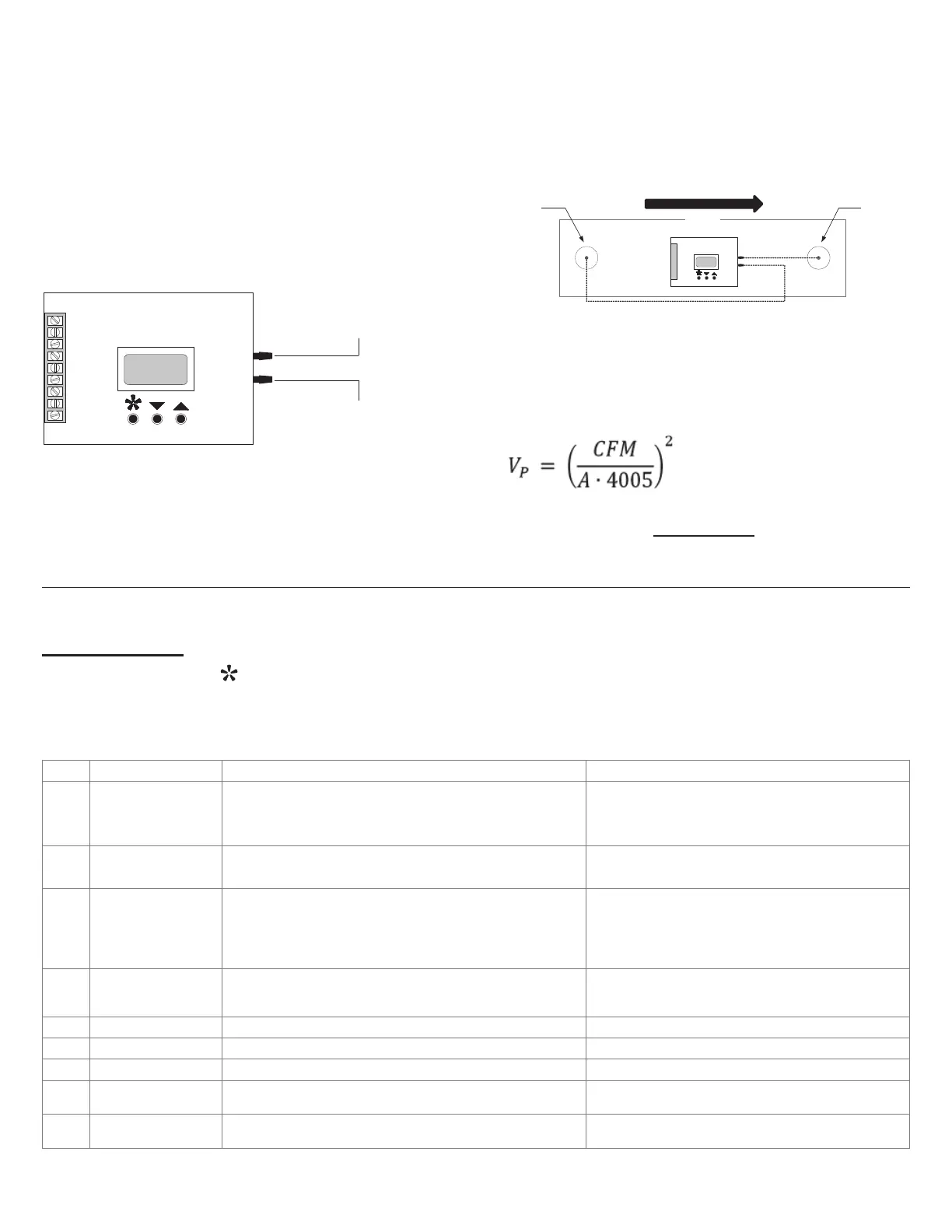

Two Room Taps

The Two Room Taps maintain a constant dierential pres-

sure between two rooms. This constant dierential pressure

enables the controller to monitor and regulate the pressure

through the Pressure Controller when placed at a remote lo-

cation. To connect the Two Room Taps:

• Use a 1/8” (3.175 mm) tubing to connect between the

pressure tap in the high pressure room and the HIGH

pressure port on the Pressure Controller.

• Use a 1/8” (3.175 mm) tubing to connect between the

pressure tap in the low pressure room and the LOW

pressure port on the Pressure Controller.

Com

24V~

Prs +

Rev

Dir

Ext

Kcom

Knc

Kno

Static Pressure Tap

Low Pressure Port

High Pressure Port

Total Pressure Tap

1/8" (3.175mm) Tubing

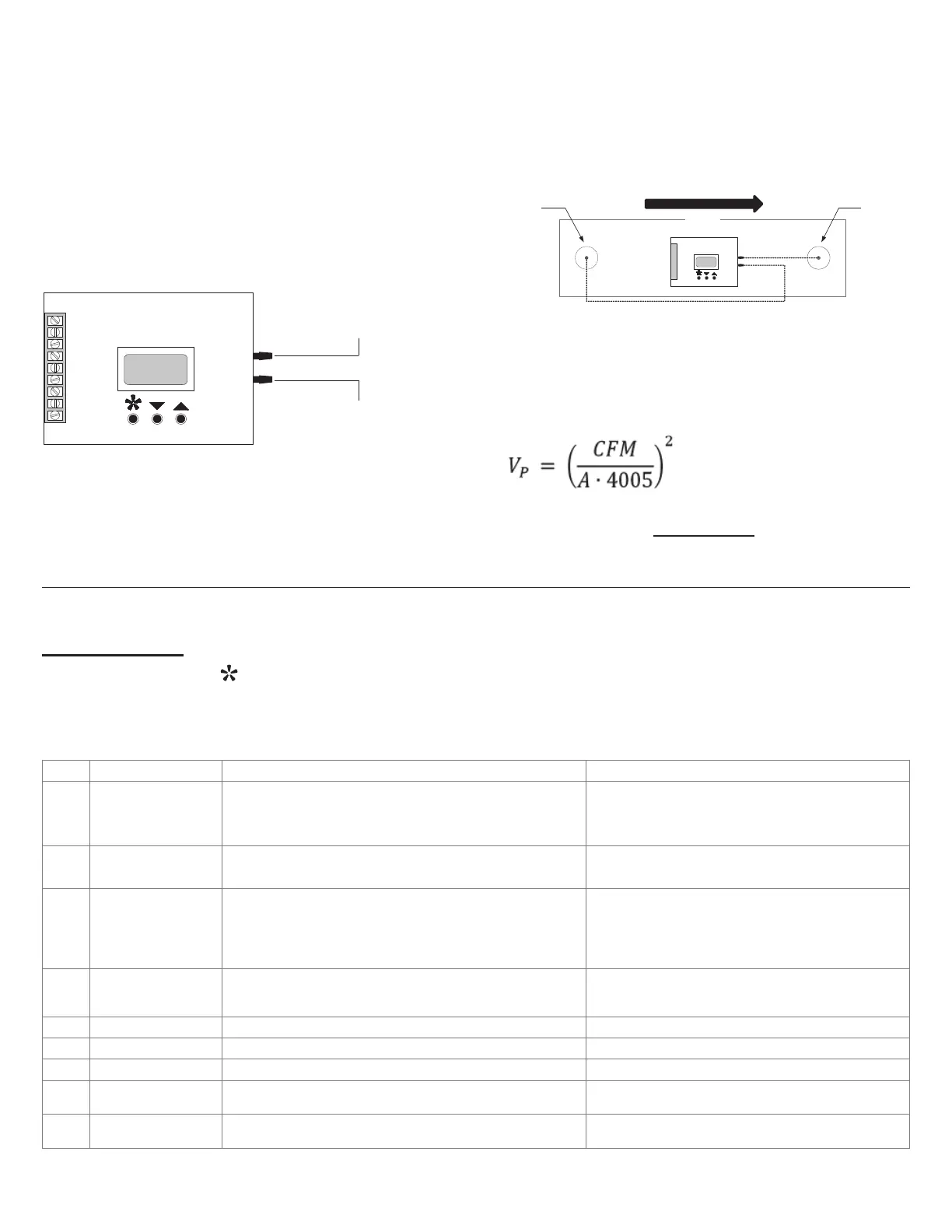

Velocity Pressure Control

One Duct Static Tap and One Duct Total Tap

The One Duct Static Tap and One Duct Total Tap maintain

a constant velocity pressure in a duct. This constant velocity

pressure enables the controller to modulate the airow auto-

matically to compensate for lter or coil loading. To connect

the Duct Static and Total Tap:

• Use a 1/8” (3.175 mm) tubing to connect between the

total pressure tap and HIGH pressure port on the Pres-

sure Controller.

• Use a 1/8” (3.175 mm) tubing to connect between the

static pressure tap and LOW pressure port.

Static

Pressure Tap

Low Pressure Port

High Pressure Port

Duct

Total

Pressure Tap

Air Flow

In this conguration, the Pressure Controller maintains a

velocity pressure by measuring and maintaining the dier-

ence between total and static pressure read at the HIGH and

LOW pressure ports. To set up the controller, calculate the

required velocity pressure based on the intended CFM and

duct area using the following formula:

where A is the duct area in ft

2

Set the desired pressure setpoint parameters from the Pro-

gramming menu (see Programming). To verify the airow

calculation, take external CFM measurements and calculate

the velocity pressure until the desired airow is achieved.

Step

Display Description Values

1

Pr:X.XXX

Sp:X.XX

Operation Mode & Setpoint Adjustment

When 24 Vac is supplied to the unit, the SPC displays the actual

pressure (Pr) and the setpoint of the static pressure (Sp). Use the arrow

keys to change the setpoint.

Increments of 0.01

Units - in w.c. (inches of water column)

Range - 0.00 to 1.99

2

Deadband

(range: 0.000-0.243)

Deadband Adjustment

Not generally important for EC motor control

Default: 0.014 (SPC 1.0), 0.0014 (SPC 0.1)

Increment: 0.005 (SPC 1.0), 0.0005 (SPC 0.1)

3

Response Speed:

(range: 1-25)

Response Speed Adjustment

Prevents unjustied changes due to a temporary surge of static

pressure, which could aect the system. To increase system stability,

we recommended setting the Response Speed to lower end of range

(setting 1 or 2).

1 to 25 (factory setting: #2)

1 lowest: (100 mV/sec, 100 seconds for a 0-10 Vdc output).

25 fastest: (1.78 V/sec, 5.6 seconds for 0-10 Vdc output).

4

Cntl Out

Output Signal Adjustment

The conguration of the output signal applies to both direct acting and

reverse acting.

▲ or ▼ = 0-10 Vdc / 2-10 Vdc

5

Direct Act: Direct acting output conguration ▲ or ▼ = Vdc or mA (Set to Vdc for EC motor control)

6

Reverse Act: Reverse acting output conguration ▲ or ▼ = Vdc or mA (Set to Vdc for EC motor control)

7

Contact: Relay conguration Direct or Reverse

8

Contact On: Relay SETPOINT (Sp) to come ON Contact Direct: 0.31-2.00 ”wc Contact Reverse: 0.00-0.31 ”wc

9

Contact O: Relay SETPOINT (Sp) to turn OFF Contact Direct: 0.00-0.31 ”wc Contact Reverse: 0.31-2.00 ”wc

Programming

Press the menu button

to enter programming mode. Once in programming mode, the menu button always advances to

the next step. Use the arrow keys to change the value of the current menu item. Press and hold an arrow key to scroll rapidly

through the values. Changes are automatically saved. The Vari-Flow Pressure Controller automatically exits the menu after 20

seconds of inactivity.

Loading...

Loading...