VARI-FLOW PRESSURE CONTROLLER IO&M

B51004-002

4

Corporate Oces 2015 E. Dale Street Springeld, MO 65803

Phone 417-869-6474 Fax 417-862-3820 LorenCook.com

Limited Warranty

Loren Cook Company warrants that your Loren Cook fan was manufactured free of defects in materials and workmanship, to the extent stated herein. For a period of one (1)

year after date of shipment, we will replace any parts found to be defective without charge, except for shipping costs which will be paid by you.

This warranty is granted only to the original purchaser placing the fan in service.

This warranty is void if the fan or any part thereof has been altered or modied from its original design or has been abused, misused, damaged or is in worn condition or if the fan

has been used other than for the uses described in the company manual. This warranty does not cover defects resulting from normal wear and tear.

To make a warranty claim, notify Loren Cook Company, General Oces, 2015 East Dale Street, Springeld, Missouri 65803-4637, explaining in writing, in detail, your complaint

and referring to the specic model and serial numbers of your fan. Upon receipt by Loren Cook Company of your written complaint, you will be notied, within thirty (30) days of our

receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty relief, a warranty adjustment will be completed within sixty

(60) business days of the receipt of your written complaint by Loren Cook Company.

This warranty gives only the original purchaser placing the fan in service specically the right. You may have other legal rights which vary from state to state.

For fans provided with motors, the motor manufacturer warrants motors for a designated period stated in the manufacturer’s warranty. Warranty periods vary from manufacturer

to manufacturer. Should motors furnished by Loren Cook Company prove defective during the designated period, they should be returned to the nearest authorized motor service

station. Loren Cook Company will not be responsible for any removal or installation costs.

DECEMBER 2018

Controller does not hold setpoint pressure

Cause:

∙ Incorrect minimum distance

∙ Kinks or punctures in the tubing.

Corrective Action:

∙ Ensure that the pressure taps are located at a minimum distance

of 1.5 duct diameters upstream or downstream from any dimensional

change, elbow, damper, or other obstruction.

∙ Verify and ensure that there are no kinks or punctures in the tubing

between the Pressure Controller and the pressure taps.

Unstable Fan Speed

Cause:

∙ Kinks or punctures in the tubing.

∙ Response Speed set too high.

Corrective Action:

∙ Verify and ensure that there are no kinks or punctures in the tubing

between the Pressure Controller and the pressure taps.

∙ Adjust the response speed from the Programming Menu (see Step

3 - Programming).

PROBLEM AND POTENTIAL CAUSE

TroubleshootingContact Modes/Actions

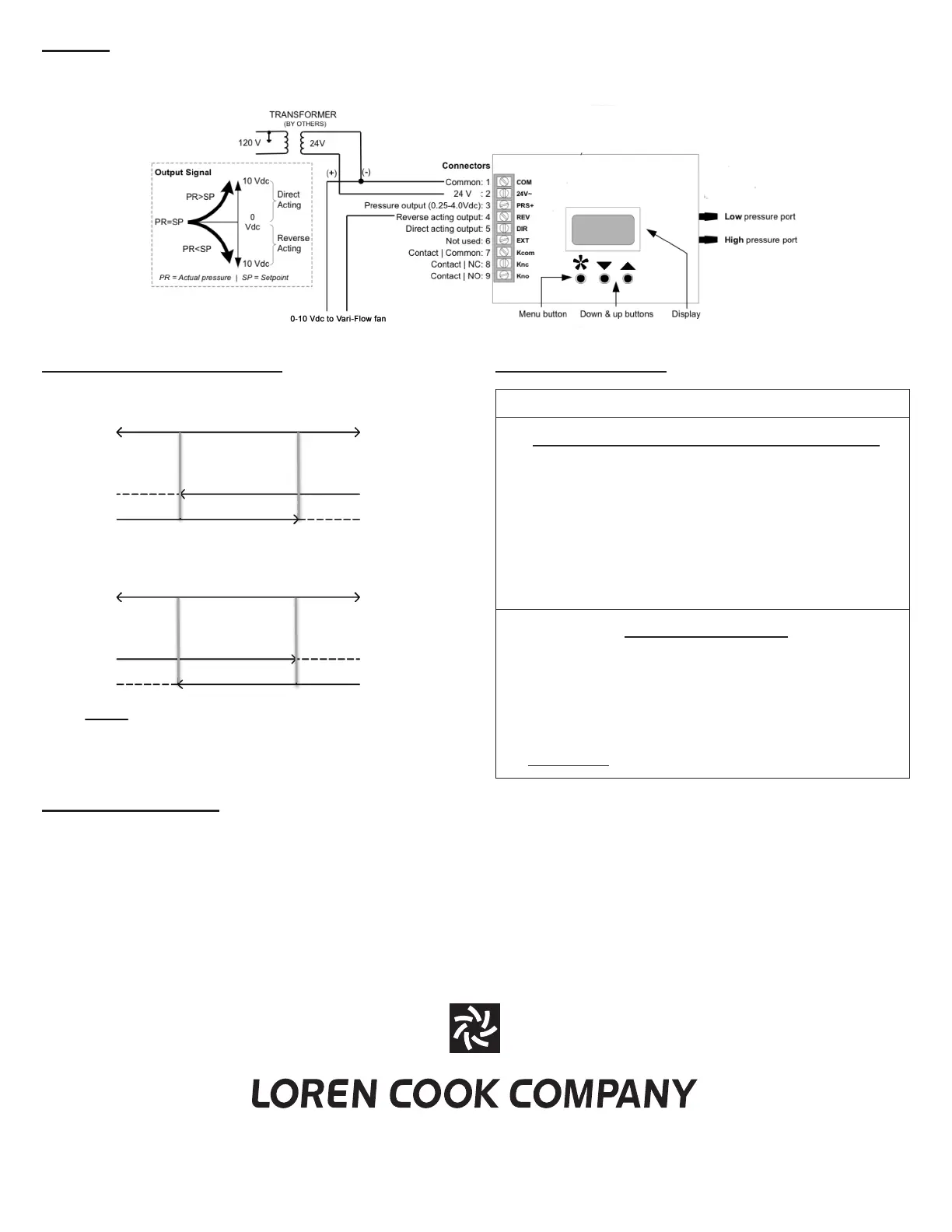

Wiring

We strongly recommend that each product be wired to a separate grounded transformer and that the transformer shall service

only these products. This precaution will prevent interference with and/or possible damage to incompatible equipment.

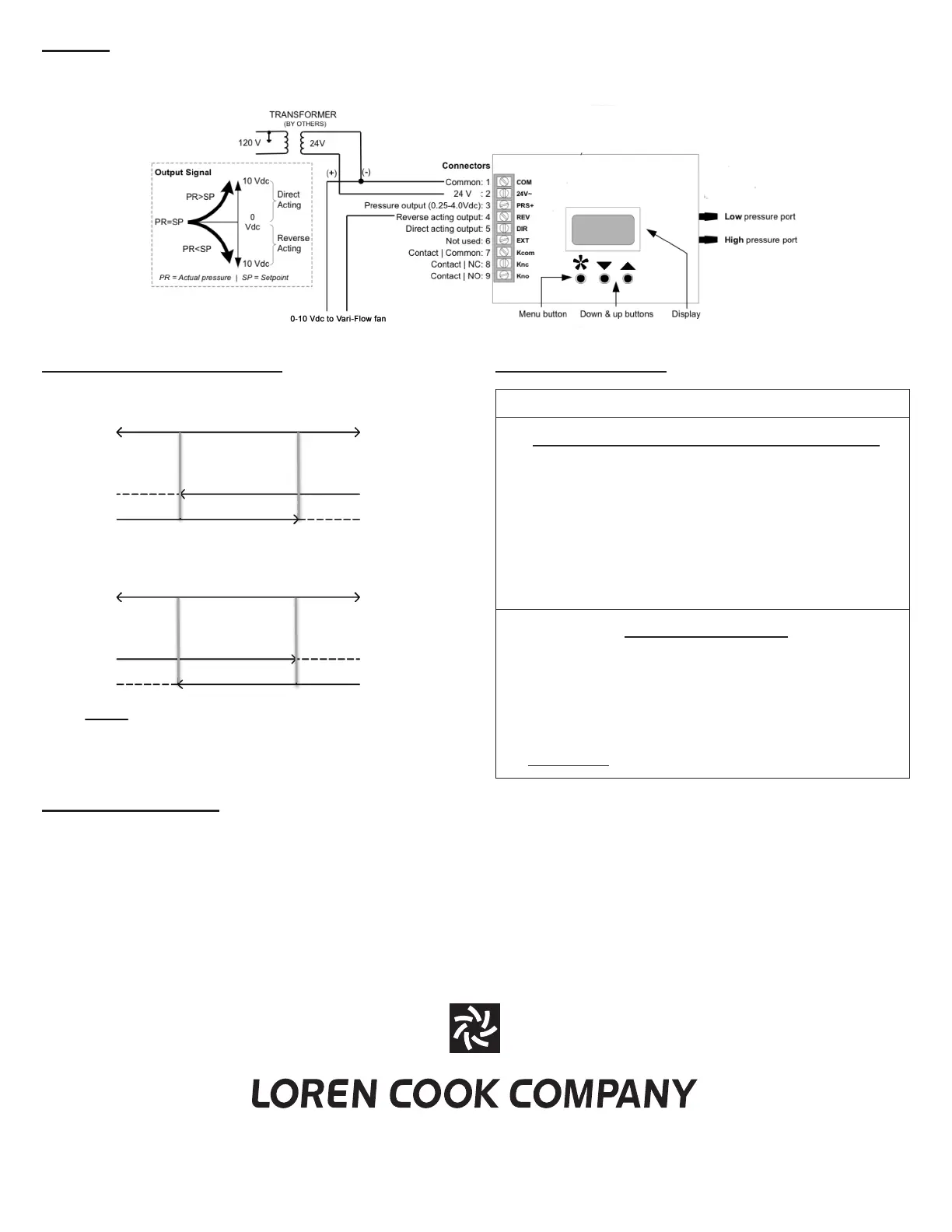

OFF ON

- +

OFF

Legend

Dashed = Open

Solid = Closed

ON

- +

K

nc

= Closed

K

no

= Open

K

nc

= Open

K

no

= Closed

K

nc

= Open

K

no

= Closed

K

nc

= Closed

K

no

= Open

Pressure

Differential

Pressure

Differential

Direct Acting

Reverse Acting

Loading...

Loading...