1

The parallel countermarch system

In a countermarch loom, every shaft is actively

involved in each shed: Each shaft is either lifted

or pulled down by each treadle.

Uneven sheds, for example a satin weave

shed, where four shafts are lifted and one is

pulled down, open cleanly every time. The warp

ends on the fifth shaft do not tend to ride up as

they often do with jack looms.

When the shed is made, the same tension is

applied to the raised ends as to the lowered

ones, resulting in the best shed in relation to the

increase of the warp tension.

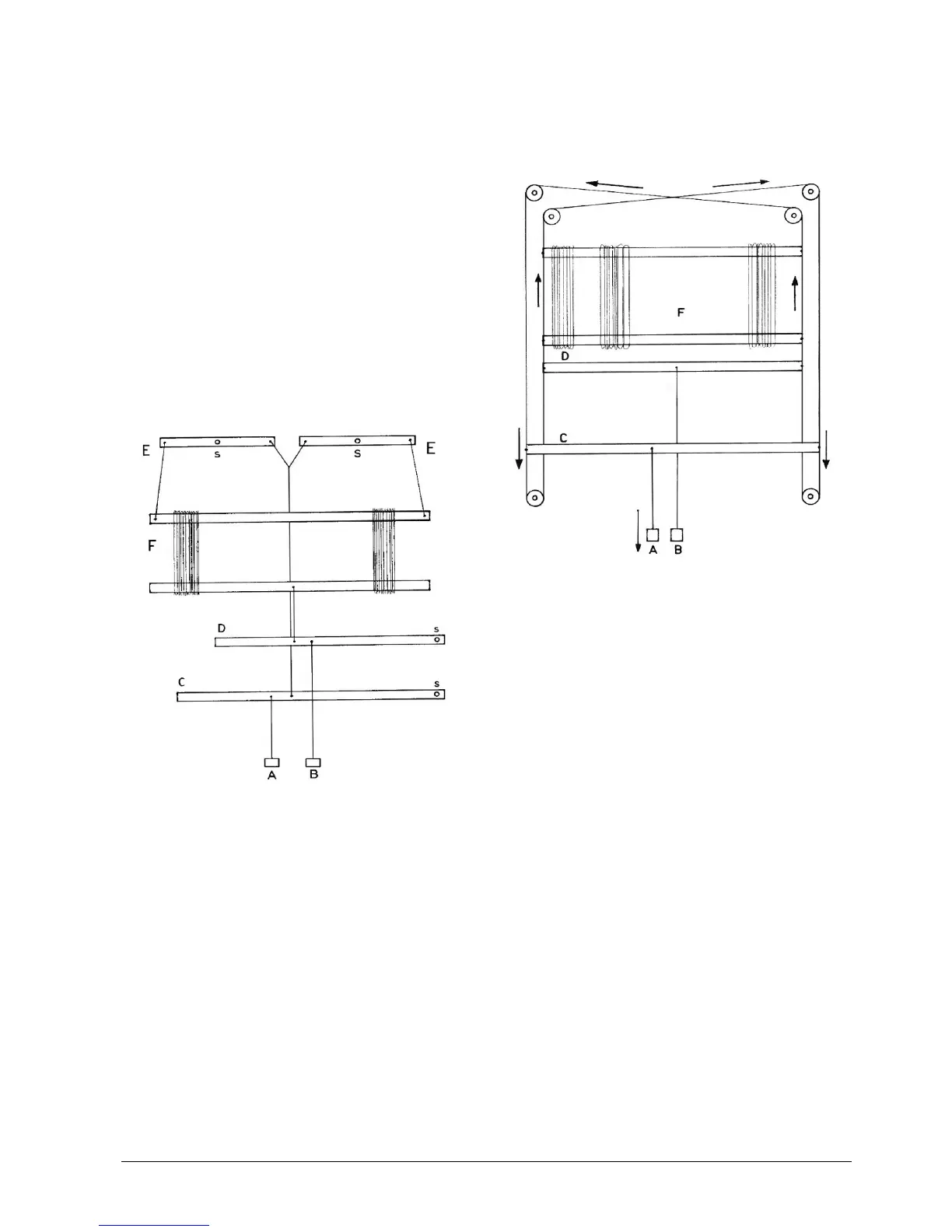

Traditional countermarch system

Look at the diagram to help you understand

how a countermarch loom works. The points

marked S are the pivoting points for the lams C

and D and the jacks E.

You will see that beneath each shaft, there are

two lams associated with it. One of those lams

is directly connected to the shaft and moves in

the same direction as it does: when this lam is

pulled down, the shaft moves down. When the

other lam is pulled down, the shaft rises.

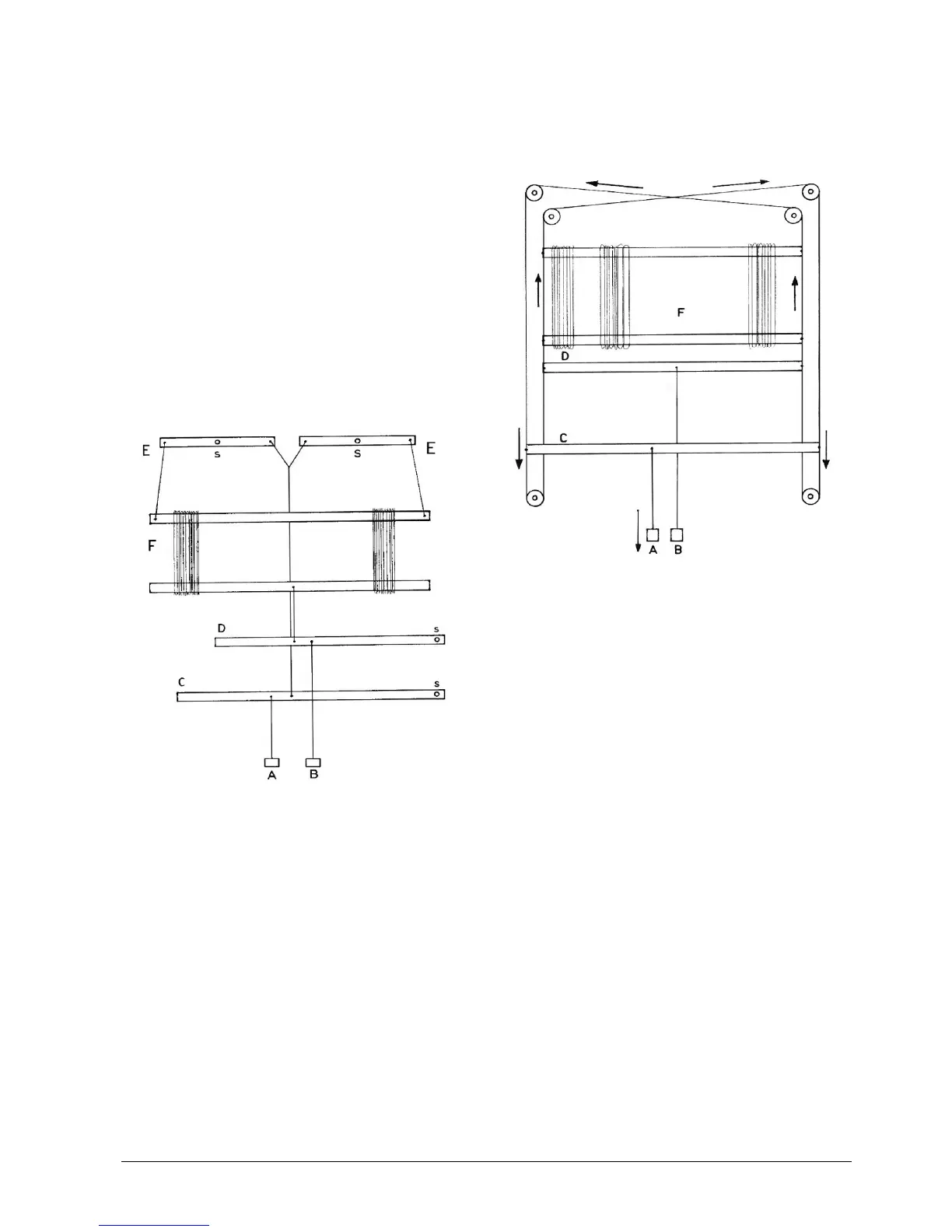

Parallel countermarch

Each shaft is attached to a cord, which goes

over all six rollers. The ends of the cord are

joined, so the cord forms a continuous loop.

When treadle A is pressed down, the lower lam

C, attached to the outside part of the cord,

moves downward, pulling the shaft F up. When

treadle B is pressed down, the upper lam D

attached to the inside part of the cord, goes

down, pulling the shaft with it.

Compared to the traditional countermarch, the

parallel countermarch has five nice features:

1. In contrast to the traditional countermarch,

the lams of the parallel countermarch stay

horizontal, while moving the same distance

as the shafts. This means that the action of

all treadles is the same, not depending on

their location in the width of the loom.

2. The parallel countermarch system is more

compactly constructed, because the action

space the lams need is less than pivoting

lams and the rollers at the top take less

space than jacks.

3. Shaft bars and lams cannot slant. Their

ends are fixed to the cord and when the

cord moves, all parts of the cord have to

move the same distance.

4. There is no tie-up to the middle of the lower

shaft bars, so the heddles can be moved

freely over the shafts.

5. There are no cords, connecting the lams to

jacks, running through the middle of the

warp

Because each treadle is tied to one of the lams

of each shaft, twice as many tie-ups per treadle

must be made, on the average, compared to

looms with another system.

Before the advent of Texsolv cord, the time

required to tie up a countermarch loom was

Loading...

Loading...