Page 6 of 18 507388-01Issue 1504

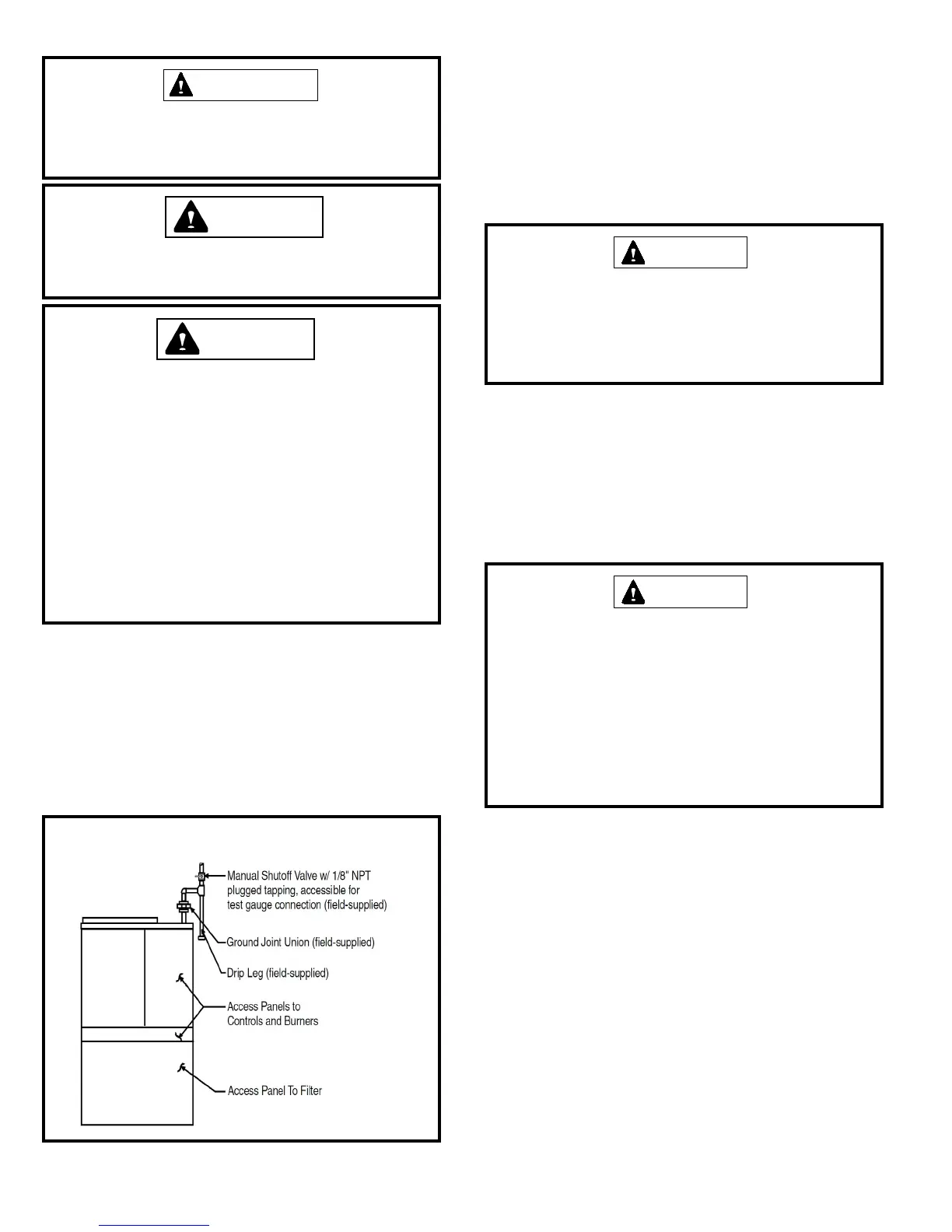

A manual shuto valve must be located outside the unit. The use

of a union located upstream of the controls is recommended,

between the controls, and the manual shuto valve. This will

facilitate removal of controls and manifold. See Figure 3 for

recommended placement of the union.

Provide a drip leg in the supply piping located exterior to the

unit. Piping must be ght and non-hardening. Pipe compound

resistant to propane must be used.

Electrical Connecons

All wiring must be done in accordance with the National

Electrical Code, ANSI/NFPA No. 70 (latest edion); Canadian

Electrical Code Part 1, CSA C22.1 (latest edion); or local codes,

where they prevail. Any alteraon of internal wiring will void

cercaon and warranty.

The rang plate indicates the operang voltage, phase, minimum

circuit ampacity, maximum fuse size, and minimum voltage. Units

must never be installed where voltage exceeds 10% over the

voltage indicated on the rang plate.

Units are factory wired for a 230 volt power supply. If power

supply is 208 volts, it will be necessary to change a wire

connecon on unit transformer from 240 volt terminal to 208

volt terminal as shown on the wiring diagram.

Failure of the compressor as a result of operaon on improper

voltage voids the compressor replacement warranty.

A separate electric line with wire having a temperature rang of

60°C should be run directly from the main supply panel to the

leads in the unit. Refer to the rang plate located on the unit

for proper fuse or breaker size. Make sure the unit is electrically

grounded in accordance with local codes or, in the absence of local

codes, with the Naonal Electrical Code, ANSI/NFPA No. 70 (latest

The furnace must be isolated from the gas supply piping

system by closing the individual manual shutoff valve

during any pressure tesng of gas supply piping system at

test pressures equal to or less than 1/2 psig or 14” W.C. If

the piping system is to be tested at pressures in excess of

1/2 psig, the furnace and its individual shuto valve must

be disconnected from the gas supply piping system. The

gas valve supplied with this furnace is rated at 1/2 psig.

Any higher pressure may rupture the pressure regulator

diaphragm which will cause overring of the burners and

improper burner operaon. This acon may produce a

high concentraon of carbon monoxide which can result

in asphyxiaon.

WARNING

Figure 3

Gas Supply Piping

Leak Check

After gas piping is completed, carefully check all piping

connecons (factory and eld installed) for gas leaks. Use a leak

detecng soluon or other preferred means.

NOTE: If emergency shutoff is necessary, shut off the main

manual gas valve and disconnect the main power to the

furnace. The installer should properly label these devices.

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly after

leak test has been completed. Do not use matches,

candles, ame or other sources of ignition to check for

gas leaks.

CAUTION

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and service

to protect the furnace’s electronic controls. Precautions

will help to avoid control exposure to electrostatic

discharge by putting the furnace, the control and

the technician at the same electrostatic potential.

Neutralize electrostatic charge by touching hand and

all tools on an unpainted unit surface, such as the gas

valve or blower deck, before performing any service

procedure.

CAUTION

Compounds used on threaded joints of gas piping must

be resistant to the actions of liquied petroleum gases.

IMPORTANT

Never use a ame to check for gas leaks. Explosion causing

injury or death may occur.

CAUTION

Loading...

Loading...