11 ENGLISH

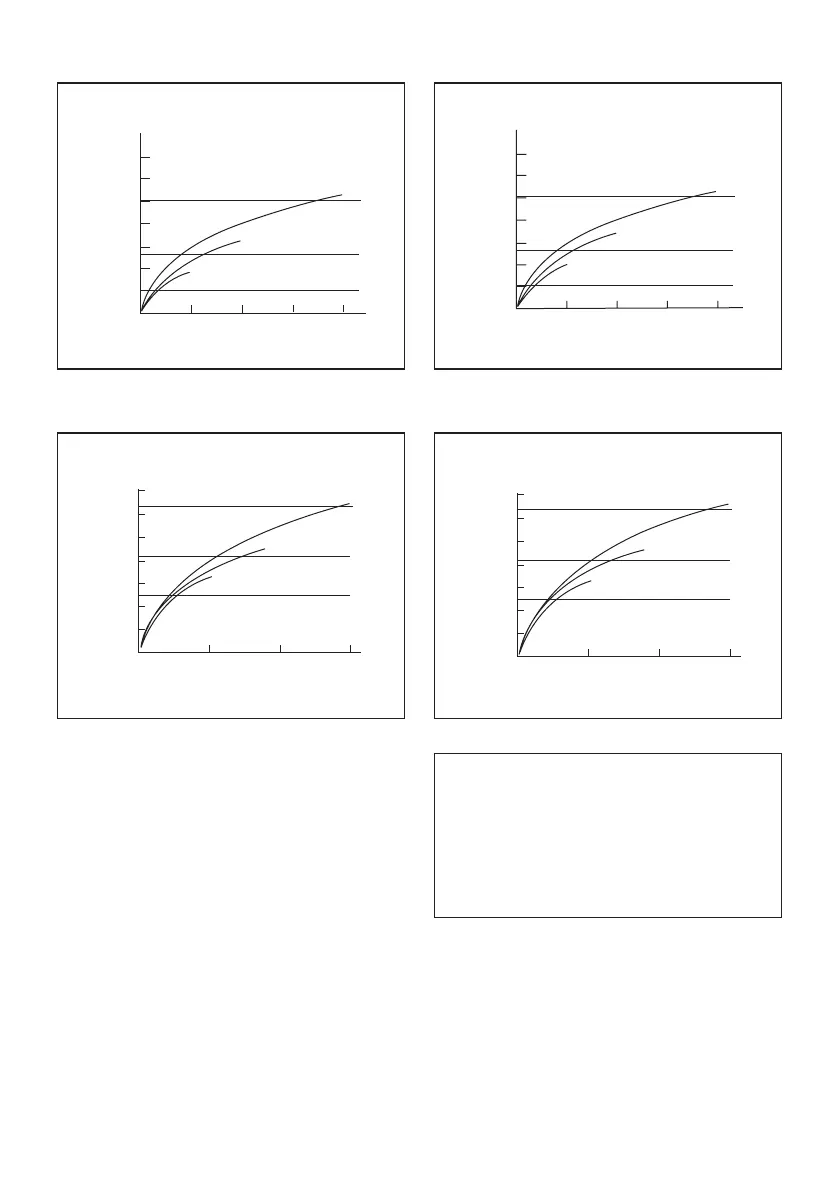

Model DTW284

Proper fastening torque for standard bolt

0

M20

M16

M16

M20

M12

M12

280

240

200

160

120

80

40

1

2

N•m

1. Fastening time (second) 2. Fastening torque

Proper fastening torque for high tensile bolt

123

280

240

200

160

120

80

40

1

2

N•m

0

M12H

M14H

M16H

M12H

M14H

M16H

1. Fastening time (second) 2. Fastening torque

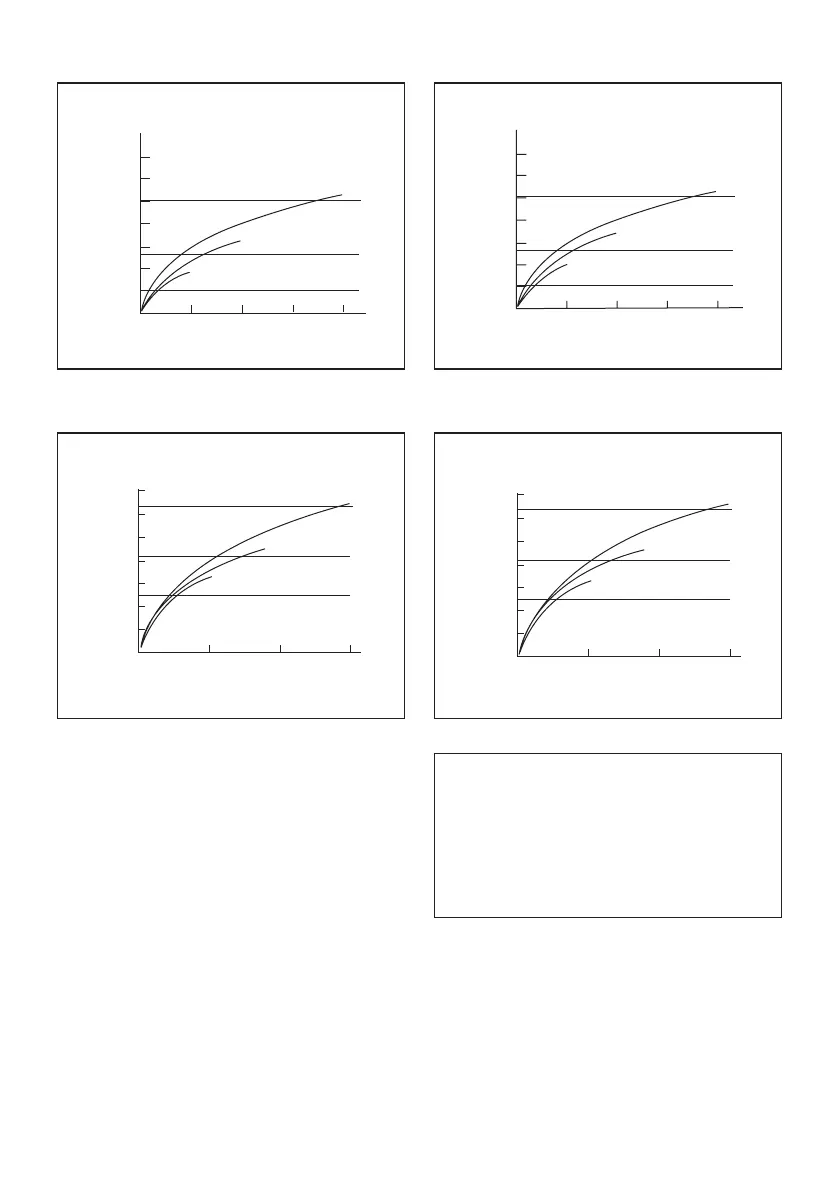

Model DTW285

Proper fastening torque for standard bolt

0

M20

M16

M16

M20

M12

M12

1

2

280

240

200

160

120

80

40

1

2

N•m

1. Fastening time (second) 2. Fastening torque

Proper fastening torque for high tensile bolt

0

160

120

80

40

200

1

M12H

280

240

M14H

M16H

M12H

M14H

M16H

1

2

N•m

1. Fastening time (second) 2. Fastening torque

NOTE: Hold the tool pointed straight at the bolt or nut.

NOTE: Excessive fastening torque may damage the

bolt/nut or impact socket. Before starting your job,

always perform a test operation to determine the

proper fastening time for your bolt or nut.

NOTE: If the tool is operated continuously until the

battery cartridge has discharged, allow the tool to rest

for 15 minutes before proceeding with a fresh battery

cartridge.

The fastening torque is affected by a wide variety of

factors including the following. After fastening, always

check the torque with a torque wrench.

1. When the battery cartridge is discharged almost

completely, voltage will drop and the fastening

torque will be reduced.

2. Impact socket

• Failure to use the correct size impact socket

will cause a reduction in the fastening torque.

• A worn impact socket (wear on the hex end

or square end) will cause a reduction in the

fastening torque.

Loading...

Loading...