CONTENTS

......................................

1 Features and Specifications 1

..................................................

1.1 Typical Applications 1

.......................................................

1.2 Testing Features 1

............................................

1.3 Technical Specifications 1

.............................

1.4 Measuring and Converting Ranges 2

...........................................................

1.5 Configuration 2

.........................

2 Structure Feature &Testing Principle 2

......................................................

2.1 Structure Feature 2

................................

2.2 Leeb Hardness Testing Principle 4

................

2.3 Symbols and illustrations of hardness scale 4

…………………………...........……

2.4 Symbols of materials 5

...............................................................

3 Preparation 5

...............................................

3.1 Weight Requirements 5

.................................... . ...

3.2 Roughness Requirements 6

........................................

3.3 Cleanliness Requirements 6

..............................................

3.4 Stability Requirements 6

...................................

3.5 Samples with curved surfaces 7

...........................................

3.6 Test Samples Properties 7

..............................................

4 Operation of the Tester 7

...........................................................

4.1 Power On/Off 7

................................ . ...

4.2 Setting your Impact Direction 7

..................................................

4.3 Selecting a material 8

........................................

4.4 Choosing a hardness scale 8

..............................................

4.5 Average Times Setting 8

...............................................

4.6 Measuring Procedure 8

......................................................

4.7 Data Memorizing 10

.........................................................

4.8 Memory Recall 10

..............................................

4.9 Delete Data in Memory 10

............................................ ... ......

4.10 Download to PC 10

................................................. ......

4.11 Auto Power Off 10

..............................................

4.12 Battery Replacement 10

................................................................

5 Calibration 10

...........................................

6 Maintenance & Servicing 11

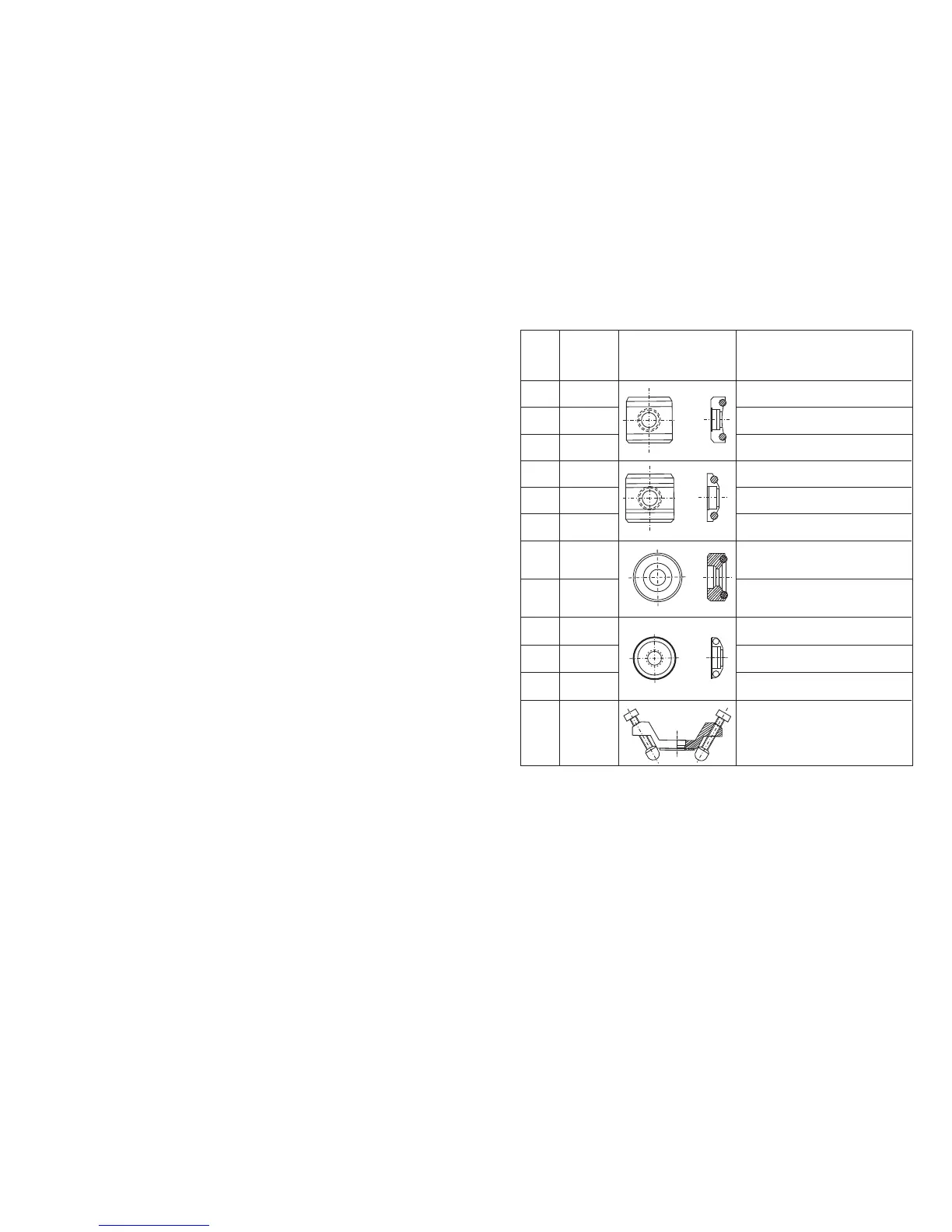

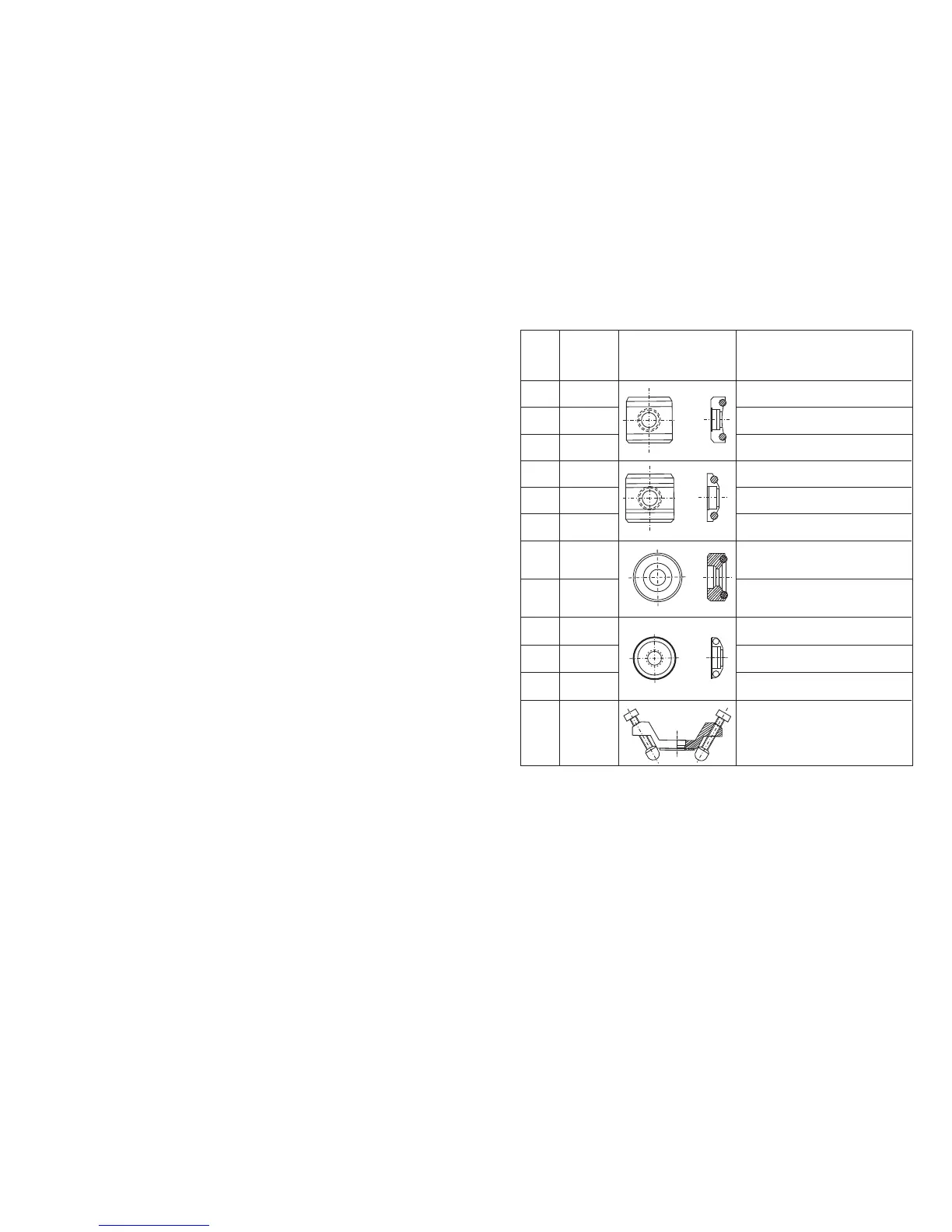

Table A

No.

Type

Sketch of

non-conventional

Supporting ring

Remarks

1

2

3

4

5

6

7

8

9

10

11

12

Z25-50

Z10-15

Z14.5-30

HZ11-13

HZ12.5-17

HZ16.5-30

K10-15

K14.5-30

HK11-13

HK12.5-17

HK16.5-30

UN

For testing cylindrical outside

surface R10~R15

For testing cylindrical outside

surface R14.5~R30

For testing cylindrical outside

surface R25~R50

For testing cylindrical outside

surface R11~R13

For testing cylindrical outside

surface R12.5~R17

For testing cylindrical outside

surface R16.5~R30

For testing spherical outside

surface SR10~SR15

For testing spherical outside

surface SR14.5~SR30

For testing spherical outside

surface SR11~SR13

For testing spherical outside

surface SR12.5~SR17

For testing spherical outside

surface SR16.5~SR30

For testing cylindrical

outside surface,

radius adjustable R10~ a

8

12

Loading...

Loading...