3 - 38

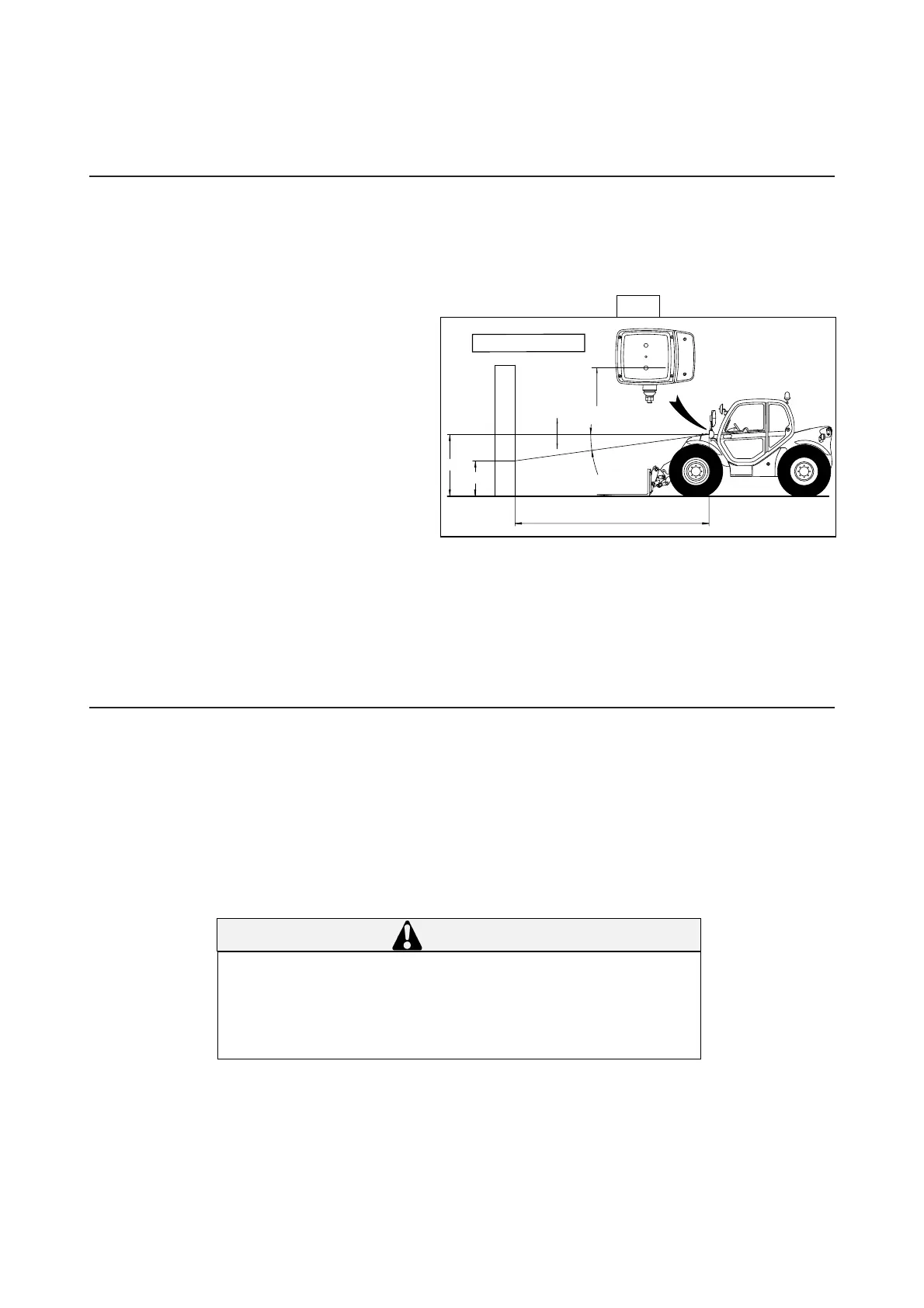

G6 - FRONT HEADLAMPS

ADJUST

RECOMMENDED SETTING

(As per standard ECE-76/756 76/761 ECE20)

Set to - 2% of the dipped beam in relation to the horizontal line of the headlamp.

ADJUSTING PROCEDURE

- Place the lift truck unloaded and in the transport

position and perpendicular to a white wall on

flat, level ground (Fig. G6).

- Check the tire pressures (See A6 - TIRES

PRESSURE AND WHEEL NUTS TORQUE in

SECTION 3 - MAINTENANCE).

- Put the gear reverser lever in neutral and

release the parking brake.

CALCULATING THE HEIGHT OF THE DIPPED BEAM (h2)

• h1 = Height of the dipped beam in relation to the ground.

• h2 = Height of the adjusted beam.

• l = Distance between the dipped beam and the white wall.

G7 - E

MERGENCY JUMP-STARTING

Read and follow the instructions carefully. If you have any questions, ask for assistance from an experienced mechanic

or contact your nearest dealer.

Before attempting a jump-start, determine the condition of the forklift’s battery: if it is damaged, has corroded

connections or weak electrolyte, it will have to be serviced or replaced before proceeding (see D10 in SECTION 3 -

MAINTENANCE for electrolyte servicing).

Jump-starting the forkllift requires a good, fully charged 12 volt battery or a vehicle with a 12 volt, negative ground

electrical system. Park the jumper vehicle next to the disabled forklift, do not allow the vehicles to touch.

Set the parking brake and turn off all electrical components on both vehicles.

Turn the jumper vehicle engine off.

Connect the jumper cables in the following sequence (continued on next page):

h1

+%

-%

l

h1

h2

-2%

h2 = h1 - (l x 2 / 100)

G6

Improper jump starting procedures can result in battery explosion.

Follow jump start instructions carefully.

Do not allow the jumper cable clamps to contact each other or any metal

surfaces (except as instructed) while attaching or removing the cables.

Use only a 12 volt, negative ground system to jump-start your forklift.

WARNING

Loading...

Loading...