3 - 36

FILLING UP THE OIL

- Clean and refit drain plug 1 (Fig. E6/1) (Tightening torque 29 to 39 N.m).

- Fill up with oil (See chapter : LUBRICANTS AND FUEL in paragraph : 3 -

MAINTENANCE) by filler port 4 (Fig. E6/2).

Use a clean container and funnel and clean the underside of the oil drum before

filling.

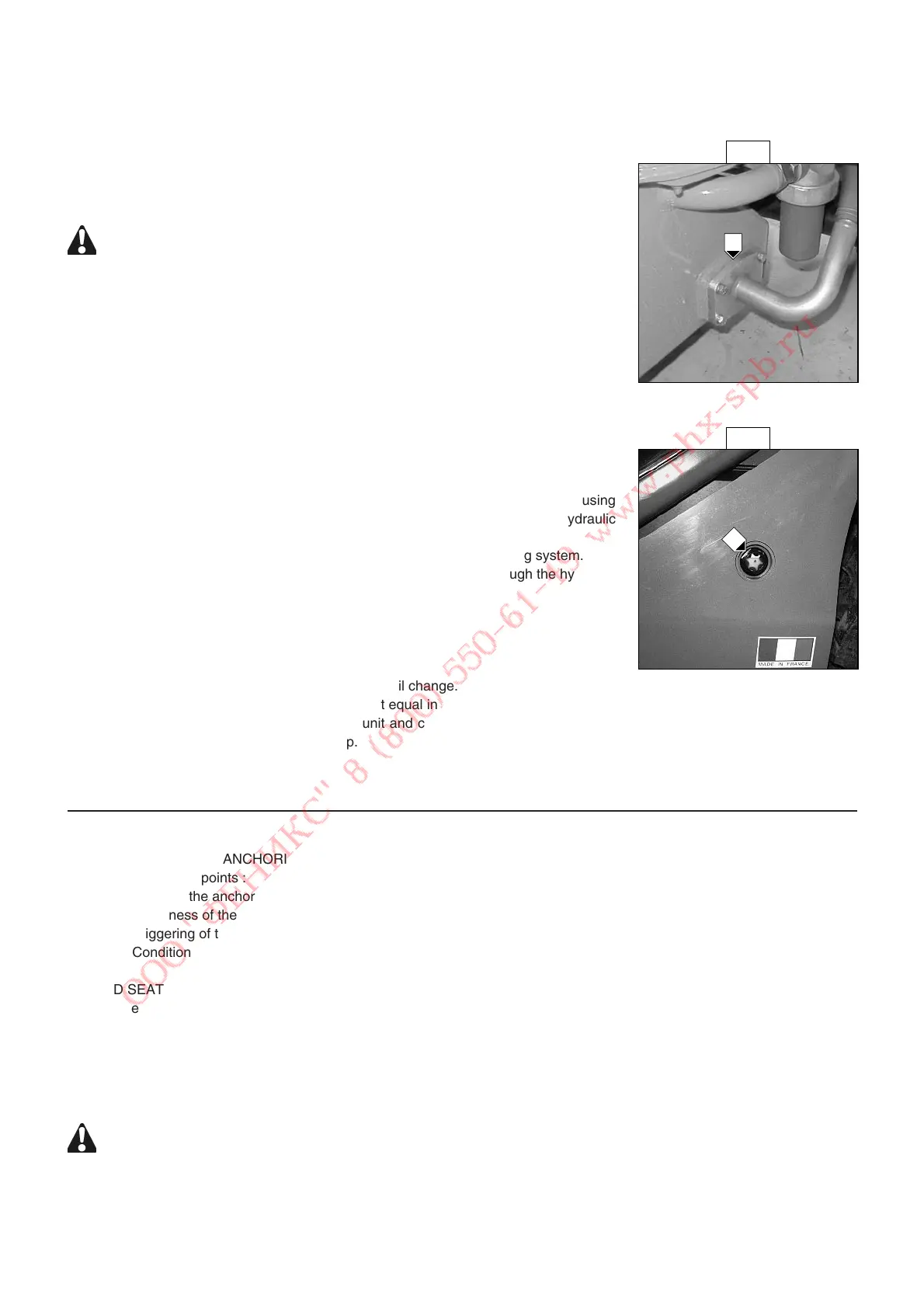

- Observe the oil level on dipstick 5 (Fig. E6/4) ; the oil level should be at the level of the

red point.

- Check for any possible leaks at the drain plug.

- Replace filler plug 2 (Fig. E6/2) with a new filler plug (See chapter : FILTERS

CARTRIDGES AND BELTS in paragraph : 3 - MAINTENANCE).

POLLUTION ABATEMENT OF THE HYDRAULIC CIRCUIT

MLT 629/730 Série A

MLT 629/730 Turbo Série A

MLT 730 Turbo POWERSHIFT Série A

MT 732/932 Série A

MT 732 Turbo Série A

- Let the engine run (Accelerator pedal at halfway travel) for 5 minutes without using

anything on the lift truck, then for 5 more minutes while using completely the hydraulic

movements (Except the steering system).

- Accelerate the engine at full speed for 1 minute, then activate the steering system.

- This operation makes a pollution abatement of the circuit possible through the hydraulic

return oil filter.

MLT 629/633/730 -120 LS Série A

MLT 633/730 LS Turbo Série A

MLT 633/730 -120 LS POWERSHIFT Série A

This should be carried out by your dealer after each oil change.

The hydraulic oil used in the circuit must be at least equal in quality to class 8 (According to NAS 1638). Your dealer will be able

to clean the hydraulic circuit using an external unit and check the quality of the oil in order to ensure the long life of hydraulic

components and particularly of the main pump.

E9 - SEAT BELT

CHECK

SEAT BELT WITH TWO ANCHORING POINTS

- Check the following points :

• Fixing of the anchoring points on the seat.

• Cleanness of the strap and the locking mechanism.

• Triggering of the locking mechanism.

• Condition of the strap (cuts, curled edges).

REELED SEAT BELT WITH TWO ANCHORING POINTS

- Check the points listed above together with the following points :

• The correct winding of the belt.

• Condition of the reel guards.

• Roller locking mechanism when the strap is given a sharp tug.

NOTE : After an accident, replace the seat belt.

Under no circumstances should you use the lift truck if the seat belt is faulty (fixing, locking, it has cuts or tears, etc). Repair

or replace the seat belt immediately.

E6/4

5

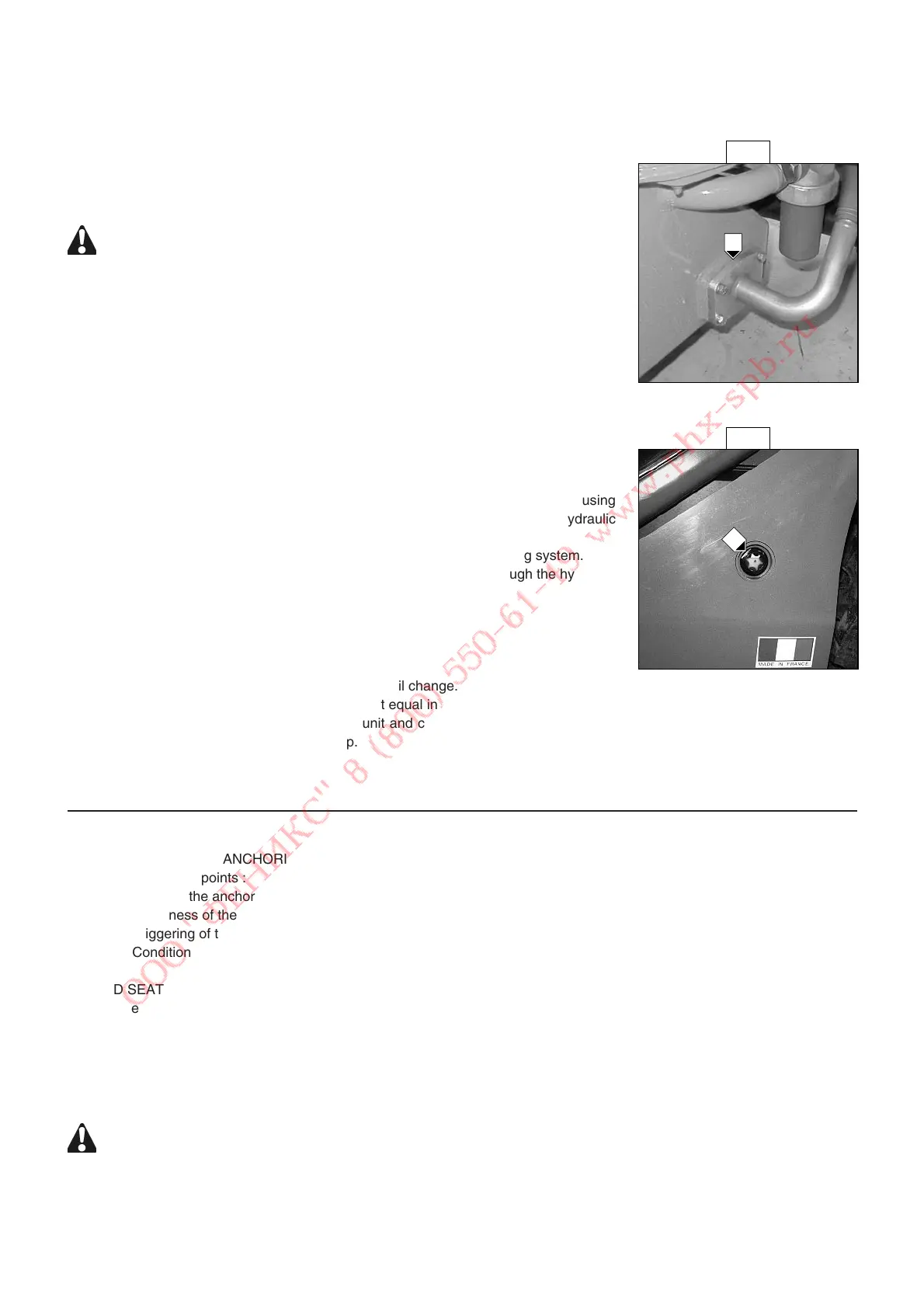

E6/3

3

Loading...

Loading...