«P2»

PRESS

BUTTON

ON THE SENSOR

«P2»

PRESS

BUTTON

ON THE SENSOR

P2

PS12-TX

60.000.016

WITHIN

8 sec.

TO

STORE

TO

DELETE

14

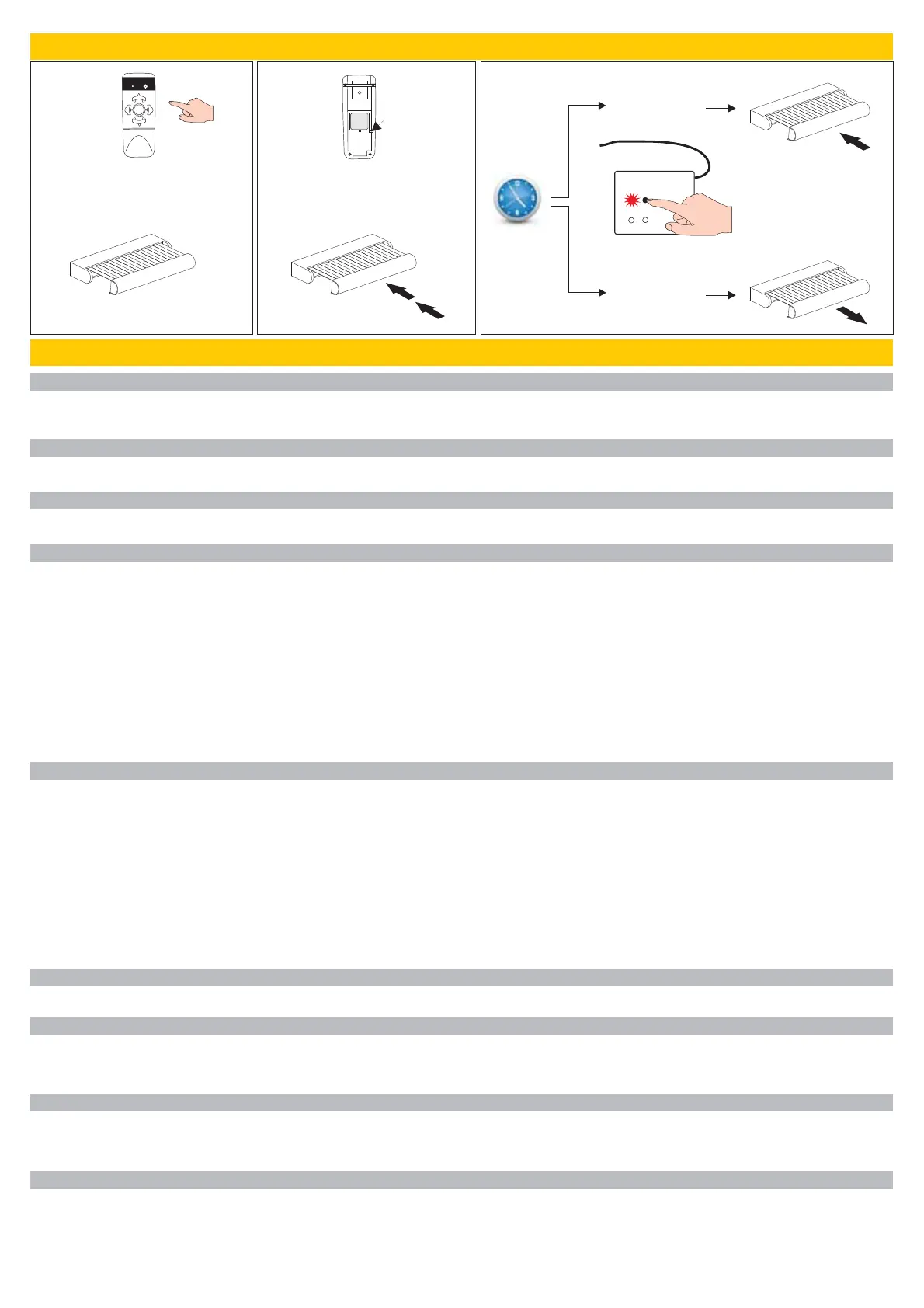

18. Memorization/deletion of a rain sensor (PS12-TX).

19. Other functions.

19.1 ROD «Rise Obstacle Detection» function - not available for screen type application

During the upward movement, the motor activates the ROD function to detect the presence of obstacles that will prevent the normal movement of the motor. If an obstacle is detected, the

upward movement is stopped and a small downward movement is operated to free the structure of the traction due to the presence of the obstacle. During this small automatic downward

movement all the manual controls are inhibited.

19.2 STS «Soft Touch System» torque control - not available for screen type application

Near the upper limit switch, the STS torque control limits the motor torque and adapts it to the weight of the roller shutter/awning to guarantee a soft lean with the obstacle that delimits the

upper limit switch.

19.3 Control on the safety catches SHD «Safety Hook Detection» - available for roller shutter application only

If the roller shutter has safety catches, the SHD function detects the presence of the safety catches, and if they are present it stops the upward movement and operates the closing of the

roller shutter without damaging it.

19.4 FOD «Fail Obstacle Detection» function - not available for screen type application

The correct operation of the downward movement obstacle detection function depends on the use of the offset adapter and its correct installation, in accordance with what is illustrated in the

previous pictures. During the downward movement, the motor activates the FOD function to detect the presence of obstacles that will prevent the normal movement of the motor. If an

obstacle is detected, the downward movement is stopped and a large upward movement is operated to allow the obstacle to be removed. During this upward movement, all the control

buttons are inhibited.

In the roller shutter or awning type installations the FOD function is normally active. In situation where the downward movement obstacle detection is not working correctly due to the

presence of structural friction that affects the natural sliding of the roller shutter or awning, it is possible to deactivate the FOD function.

Bring the motor to the intermediate position (around half way)

Press and hold of a transmitter already stored in memory for about 4 seconds, until the motor operates 2 upward movements.

B ress again . The motor operates 3 upward movements to signal the «FOD programming».

Press . The motor displays the current setting. 1 upward movement = function is ACTIVE, while 1 downward movement =function is INACTIVE.

If you want to modify the setting press . The motor displays the new setting and then returns to its normal activity.

If the setting is already the one you want, wait without carrying out any operation. After about 8 seconds the motor operates 2 downward movemetns to signal that the setting has been

modified.

To ACTIVATE/DEACTIVATE the FOD function follow this procedure:

1.

2. PROG

3. PROG

4. STOP

5. STOP

6.

riefly p entry into

19.5 Radio test function

This type of motors is able to manage information received from a radio sensor (MISTRAL RADIO, MISTRAL BATTERY, ECLIPSE RADIO, ECLIPSE BATTERY, PS12-TX). If a radio sensor

of this type is stored in the memory of the motor, a communication test is automatically activated between sensor and motor. If the communication is absent (due to failure of one or both the

devices or due to interference), the device commands an upward movement.

This movement is operated periodically (about every 20 minutes) until radio communication is restored.

To ACTIVATE / DEACTIVATE the RADIO TEST setting using a transmitter already stored in memory follow this procedure:

1. Bring the motor to the intermediate position (around half way)

Press and hold button of the transmitter already stored in memory for about 4 seconds, until the motor operates 2 upward movements.

Briefly press again . The motor operates 3 upward movements to signal the entry into «FOD programming».

Briefly press . The motor operates 4 upward movements to signal «RADIO TEST programming».

Briefly press . The motor displays the current setting. 1 upward movement = RADIO TEST ACTIVE, while 1 downward movement = RADIO TEST INACTIVE

If you want to modify the setting, press . The motor displays the new setting and returns to its normal activity.

If the setting is already the one you want, wait without carrying out any operation. After about 8 seconds the motor operates 2 downward movements to signal that the current setting has

not been modified.

2. PROG

3. PROG

4. PROG

5. STOP

6. STOP

7.

19.5 Movement operated by TIMERS

This type of motor is able to receive commands from transmitters equipped with timers, such as for example, VECTOR 24. For further information regarding the control of the motor through

timers, please contact your delear or consult the transmitter instruction manual.

19.6 Wake-up function

This function is available only if a transmitter code VECTOR 24 is stored in the memory of the motor. If a timer with transmission code F1 is set on the transmitter, on receiving the code, the

motor operates a short upward movement; after an interval of about 2 minutes, another short upward movement is operated and so on, so as to illuminate the room gradually.

Any manual (coming from control buttons or portable tranmitter) or automatic (coming from timers or radio sensors) command stops the procedure.

For any further information on the setting procedure, please refer to the transmitter VECTOR 24 instruction manual.

19.7 Self-calibration of the limit switches

If the upper limit switch has been learnt by the motor by collision with an obstacle (case of roller shutter with stoppers) the motor avoids continually colliding with the stop by stopping a few

seconds earlier. If the control electronics consider it advisable, it is possible that the roller shutter will occasionally lean with the upper stop and a limit switches calibration operation will be

carried out. The impact will in any case be soft since it is managed by the STS torque control. During the calibration operation, some small movements might be carried out during which the

manual controls are inhibited.

19.8 Compatible tranmsitters

These motors are compatible with all the transmitter series OTELLO, VECTOR, WALL and TX3 EGO and are able to store up to 40 different radio codes, one of which can be the one of a

radio sensor.

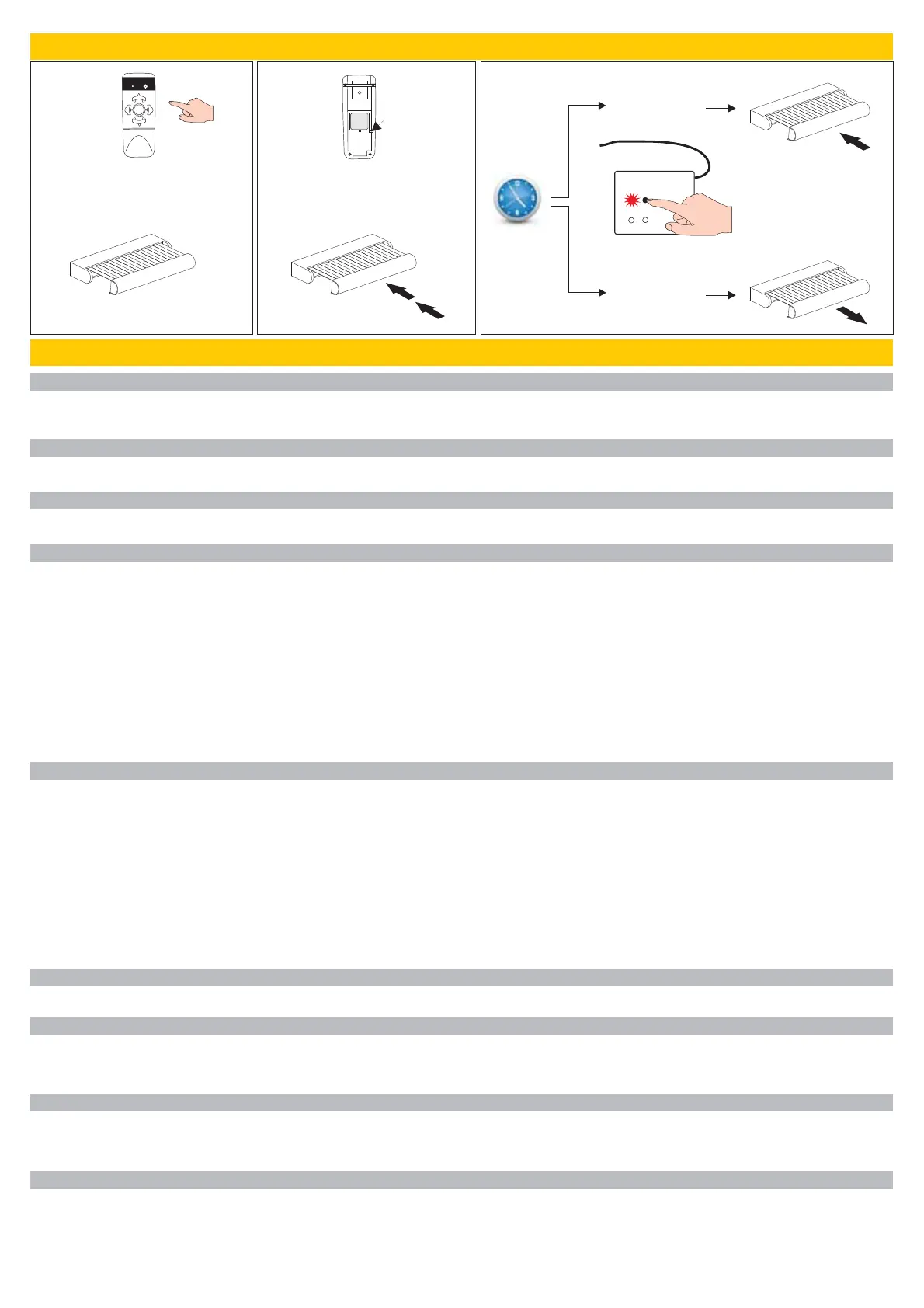

USING THE TRANMSITTER

ALREADY IN MEMORY BRING THE MOTOR

TO THE INTERMEDIATE POSITION.

INTERMEDIATE

POSITION

(around half way).

PRESS AND HOLD « » ON THE

TRANSMITTER UNTIL THE MOTOR

OPERATES 2 UPWARD MOVEMENTS

PROG

All products and technical characteristics on this document are subjects to variations without any notice.

MASTER declares that the device meets the principal requirements and the other regulations of the directive 1999/5/CE.

The declaration of conformity of the above products is available on the web site ,section «Conformity products».http://www.mastermotion.eu/it-IT/download

instruction guide STAR / VENUS rev01 16.04.12

Loading...

Loading...