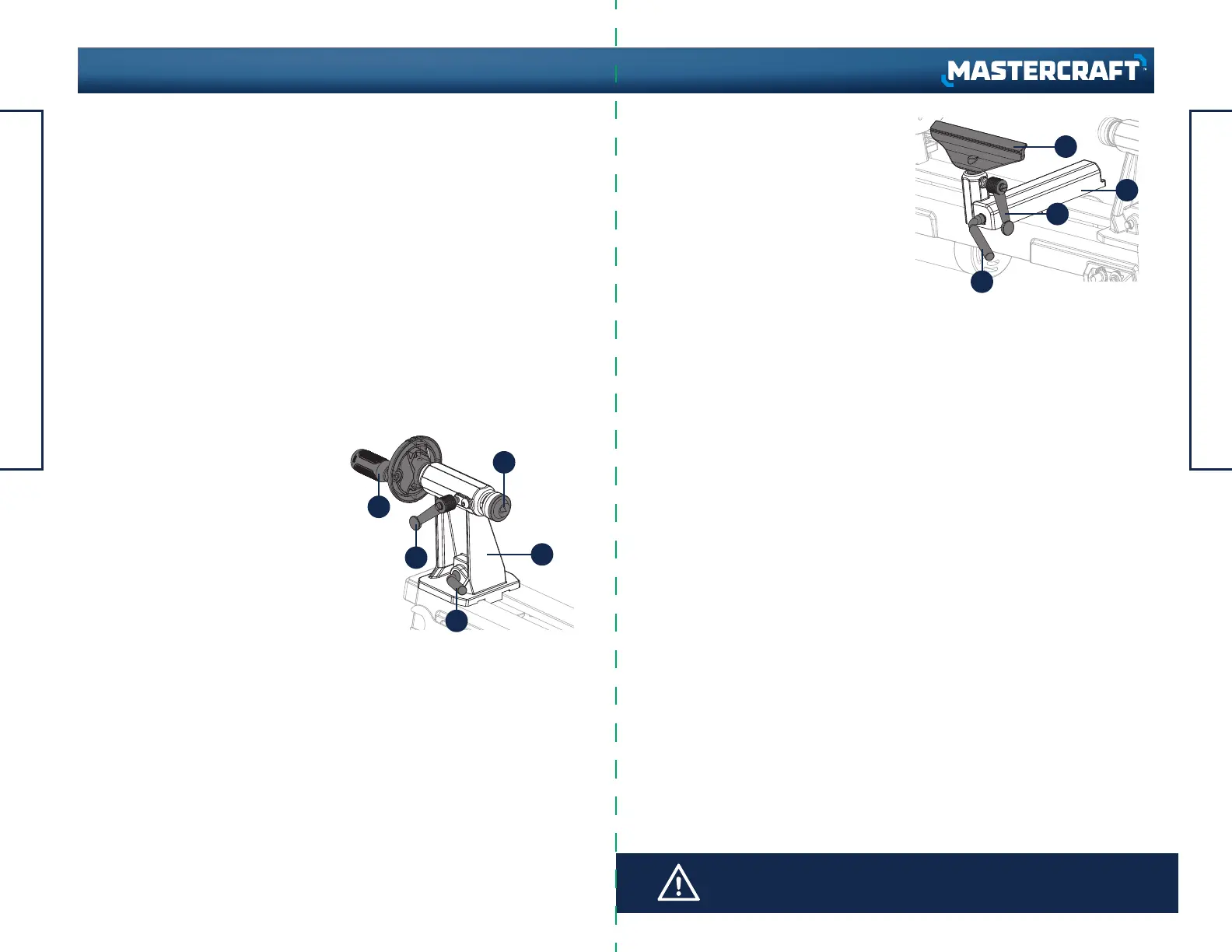

Fig. 9

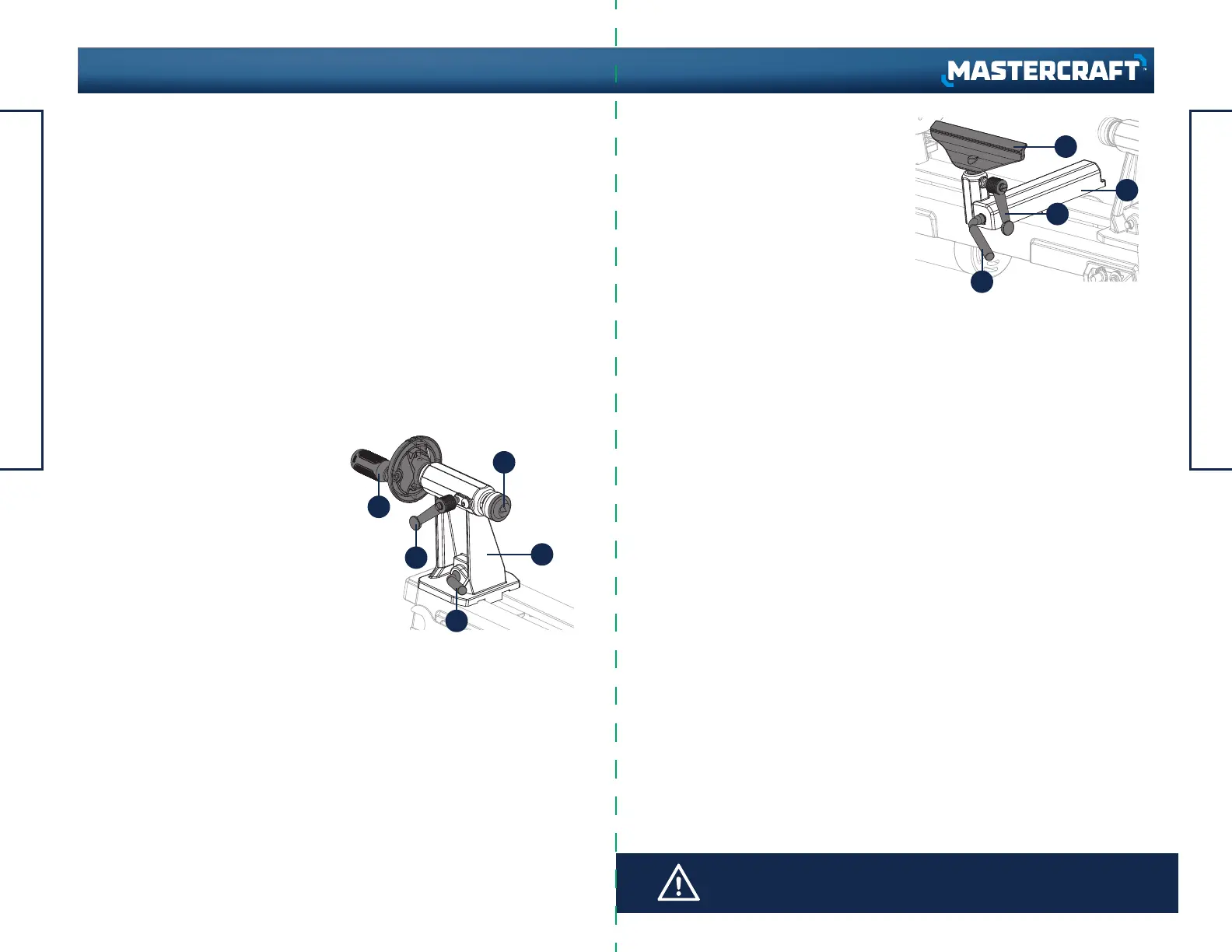

Fig. 10

1

4

1

3

5

2

2

4

3

CAUTION!

Make sure the tool rest is adjusted to be as close to the workpiece as possible. Rotate

the workpiece by hand to check clearance before starting the lathe.

TAILSTOCK (Fig. 9)

• Move the tailstock (1) by loosening the

lock lever (2) and pushing the tailstock to

the desired position on the bed. Lock by

tightening the lock lever (2).

• The spindle can extend up to 2" (5 cm)

from the tailstock housing. Move the

tailstock spindle (3) by loosening the

spindle lock lever (4) and then turning

the hand wheel (5). Turning the hand

wheel clockwise extends the spindle;

turning it counter-clockwise retracts the

spindle. Lock levers (2, 4) before

operating the lathe.

• The tailstock spindle is hollow and can

be accessed from the handwheel end.

Use the push-out rod to remove the

centre cup or to drill holes through the

centre of a workpiece on a faceplate.

USING TOOL REST (Fig. 10)

• To move the tool rest base (1), loosen the

lock lever (2), and move the base to the

right or left and back or front.

Tighten the lever (2) when the tool rest

base is in the desired position.

• To adjust the angle of the tool rest (3),

loosen the lock lever (4), move the tool

rest to the desired position, and tighten

the lock lever.

• To change to the other tool rest, loosen

the lock lever (4) and pull the tool rest (3)

out of the tool rest base, insert the other

tool rest, adjust to desired position, and

tighten the lock lever (4).

• Move the switch to the On position to start the motor. Electric current is immediately

applied to the motor. Wait for the one-to-three-second second delay in activation

before the motor begins to drive the headstock spindle. The time it takes for the

motor to reach the speed set by the speed control knob depends on the size and

weight of the workpiece.

• Move the switch to the Off position to stop the motor. Electric current is immediately

disconnected, but the spindle and workpiece will continue to spin for a few

seconds.

RESET BUTTON (Fig. 8)

The reset button (4) will restart the motor after the motor shuts off due to overloading

or low voltage. If the motor stops during operation:

• Turn the On/Off switch (1) to the Off position and wait about five minutes for the

motor to cool.

• Press the reset button (4). Turn the switch (1) to the On position.

OPERATING INSTRUCTIONS

23

22

OPERATING INSTRUCTIONS

headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

model no. 055-6793-6 | contact us 1-800-689-9928

Loading...

Loading...