9

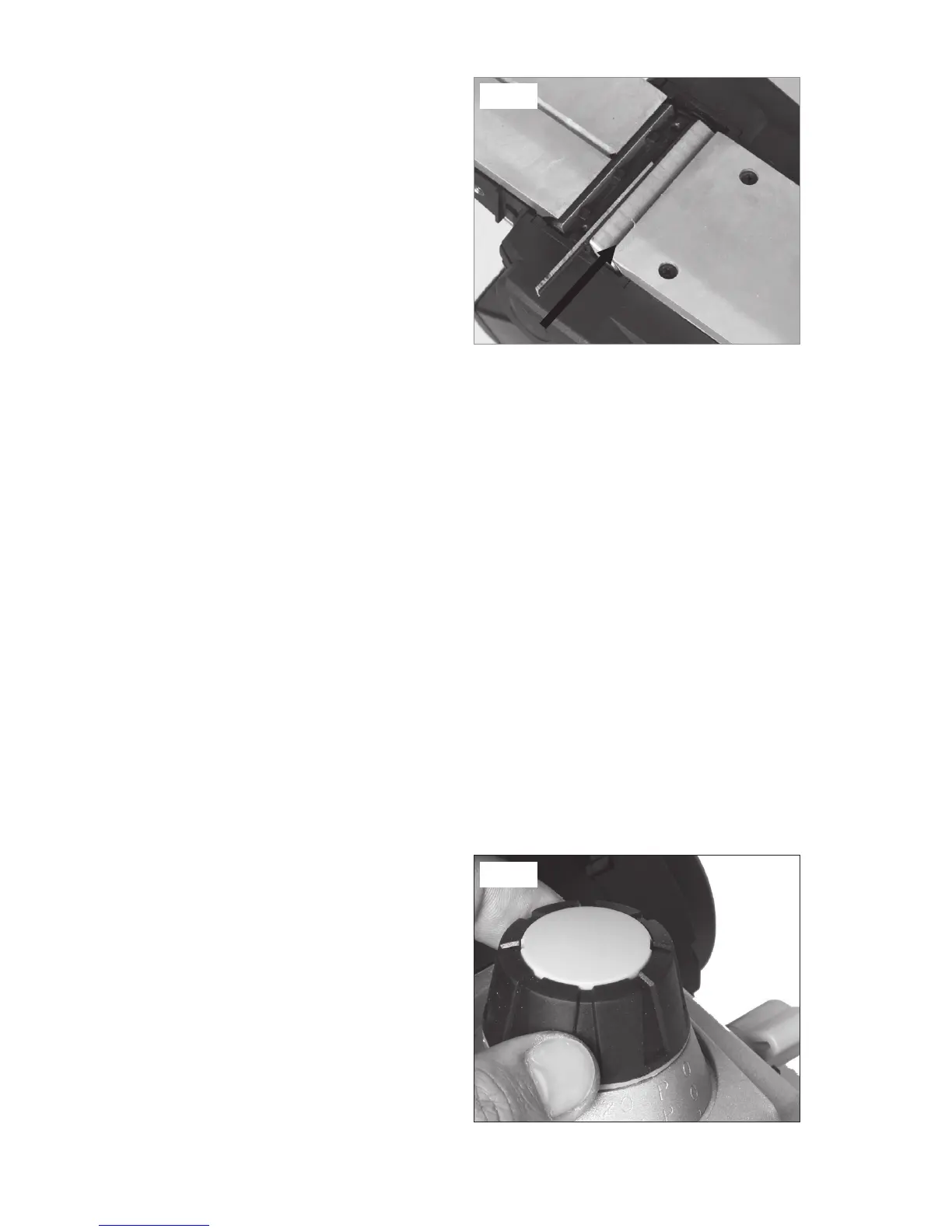

4. Slide the sharp blade face-up into

the blade-support block of the blade

barrel (10).

NOTE. The ridge along the blade

should be face away from the

clamping screws (11).

5. Evenly tighten the clamping screws

(11).

6. Repeat with the other blade.

NOTE: Always change the two blades at the same time, otherwise an

imbalance may occur and cause vibration and shorten the life of both the

blade and the tool.

NOTE: The blade position has been aligned at the manufactory, so do not

adjust the three inner hex screws on the blade supporter.

CAUTION: When installing blades, first clean out all chips and/or foreign

matter adhering to the blade barrel (10) and the blades themselves. Use

blades of the same dimensions and weight, or else the barrel will oscillate

and vibrate, causing poor planing action and tool breakdown. Tighten the

clamping screws (11) carefully when attaching the blades to the planer. A

loose clamping screw could be extremely dangerous. Regularly check to

ensure that the clamping screws are securely tightened.

NOTE: Your planing surface will end up rough and uneven unless the blades

are set properly and securely. The blades must be mounted so that the

cutting edge is absolutely level: parallel to the surface of the rear base (13).

ADJUSTING THE DEPTH OF CUT (See Fig. 5)

CAUTION: Always ensure that the

tool is switched OFF and unplugged

from the power supply before making

adjustments or installing or removing

blades.

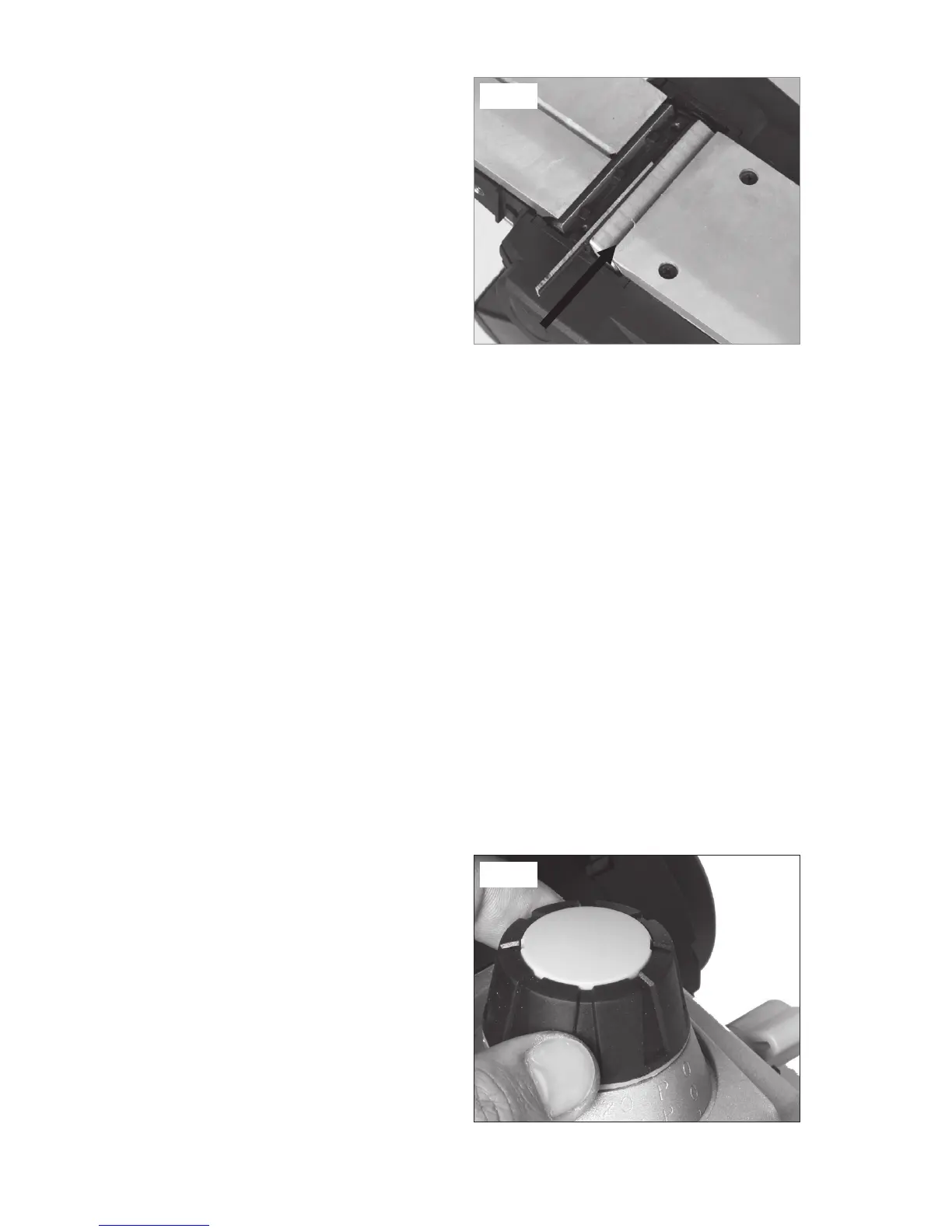

1. Rotate the depth-adjustment knob

(3) clockwise for a deeper cut

and counter-clockwise for a more

shallow cut.

2. The numbers on the ring under

the depth-adjustment knob indicate the depth of cut. For example, when

Fig. 4

Fig. 5

Loading...

Loading...