MAXEON SOLAR TECHNOLOGIES, LTD.

Safety and Installation Instructions - Document 001-15497 Rev.Z

©February 2023 Maxeon Solar Technologies, Ltd. All rights reserved. Specifications included in this manual are subject to change without notice.

No Maxeon module should be mounted at a site where it may be

subject to direct contact with salt water, or other aggressive

environment.

Modules should not be installed near flammable liquids, gases, or

locations with hazardous materials; or moving vehicules of any type.

Performance Series Mounting Orientation

Performance Series (P-Series) modules are designed to be installed in

landscape orientation. In landscape orientation, P-series modules

maintain higher power under row to row shading and edge soiling.

5.2 Mounting Configurations

Mounting system must provide a flat plane for the modules to be

mounted on and must not cause any twist or stress to be placed on

the Module, even in case of thermal expension.

Modules may be mounted at any angle from horizontal to vertical.

Select the appropriate orientation to maximize sunlight exposure.

Maxeon recommends for a good performance of the system

(reduction of soiling effect/water pooling) a minimum of 5˚ tilt angle.

The cleaning frequency must be increased for modules installed with

a very low angle.

Commercial modules (128 cells) frames have permanently attached

stacking pins located a 20mm zone on the long side frame at 388-408

mm. Mounting system hardware used with commercial modules must

account for the presence of these stacking pins (see Appendix).

Specific information on module dimensions and the location of

mounting and grounding holes is provided in Appendix.

In order to prevent water from entering the junction box, which could

present a safety hazard, modules should not be mounted such that

the front/top glass faces downward (e.g., on a tracking structure that

positions the module with the junction box facing skyward during

sleep mode).

We also want to remind that the watertightness is not ensured by the

modules but by the mounting system and that drainage should be well

designed for Modules.

Clearance between the module frames and structure or ground is

required to prevent wiring damage and allows air to circulate behind

the module. The recommended assembling clearance between

modules installed on any mounting system is a minimum of 50 mm

distance.

When installed on a roof, the module shall be mounted according to

the local and regional building and fire safety regulations. In case the

module is installed in a roof integrated PV-System (BIPV), it shall be

mounted over a watertight and fire-resistant underlayment rated for

such application

Modules mounting systems should only be installed on building that

have been formally considered for structural integrity, and confirmed

to be capable of handling the additional weighted load of the Modules

and mounting systems, by a certified building specialist or engineer.

Mounting system supplier shall manage the galvanic corrosion which

can occur between the aluminium frame of the Modules and

mounting system or grounding hardware if such devices is comprised

of dissimilar metals.

The module is only certified for use when its factory frame is fully

intact. Do not remove or alter the module frame. Creating additional

mounting holes or removing the stacking pins may damage the

module and reduce the strength of the frame, therefore are not

allowed. Using mounting Clamps or clips with additional grounding

bolts or grounding metal sheets could be in compliance with this

Safety and Installation Instructions manual subject to conditions of

Section 4.1

Modules may be mounted using the following methods only:

1) Frame Holes: Secure the module to the structure using the

factory mounting holes. Four M6 or M8 stainless steel bolts,

with nuts, washers, and lock washers are recommended per

module. Bolts to be fasten according to racking supplier

recommendations. Refer to Appendix for the module

dimensions and mounting hole locations.

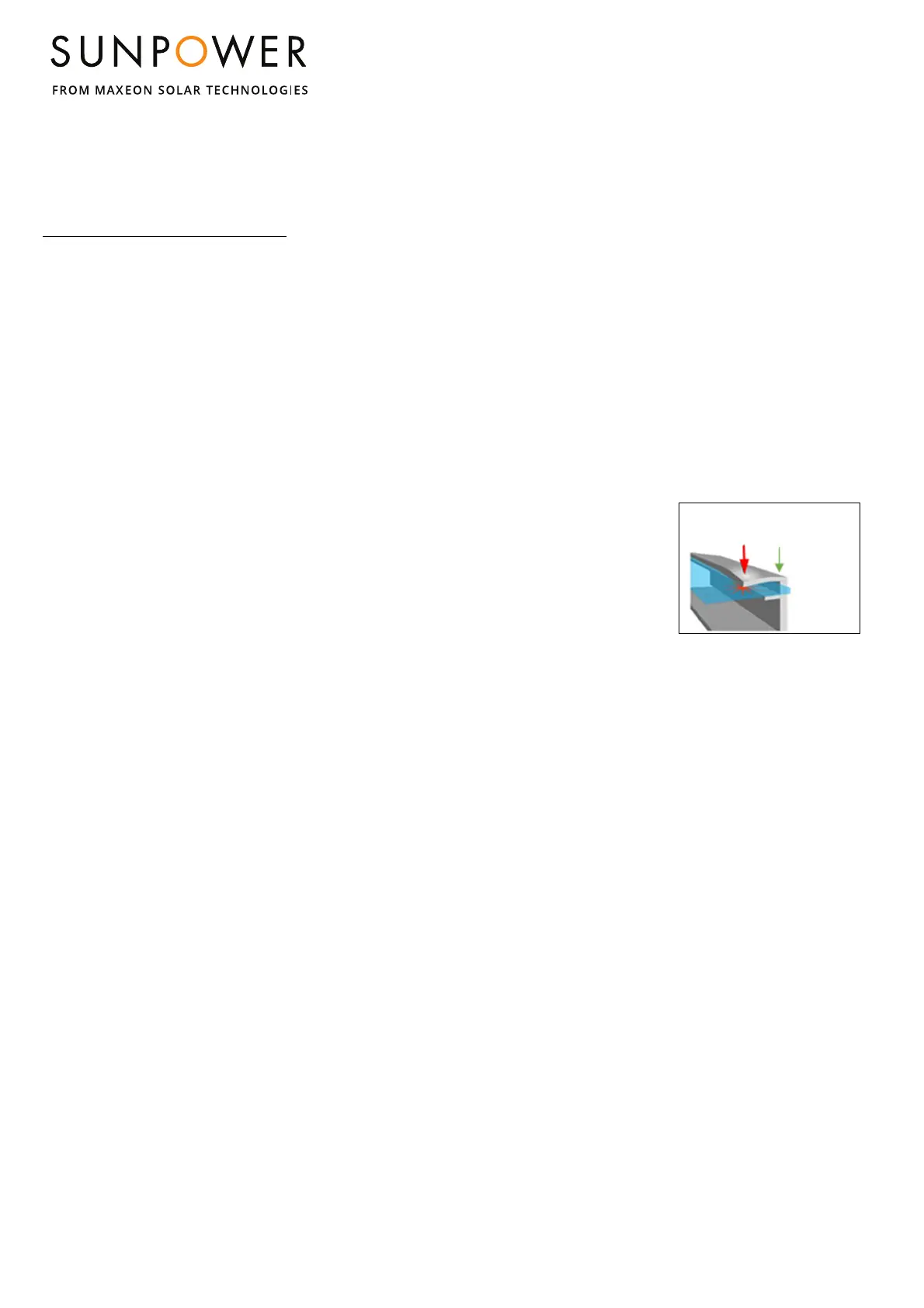

2) Pressure Clamps or Clips: Mount the module with the opposite

clips on the longer and/or shorter side of the frame of the

module. The clips allowed location should be according to Table

1.1. Installers should ensure the clamps are of sufficient

strength to allow for the maximum design pressure of the

module. Clips and clamps are not provided by Maxeon. Clamps

must apply force collinear with the ‘wall’ of the module frame

and not only to the top flange. Clamps shall not apply excessive

force to the top frame, warp the top flange, or contact the glass-

these practices void the module warranty and risk glass

breakage. Figure 1a

illustrates locations for top

frame clamp force. Avoid

clamping within 50mm of

module corners to reduce

risk of frame corner

deflection and glass

breakage. When clamping

to the module frame,

torque should never exceed 15 N.m to reduce chances of frame

deformation, if the clamp datasheets show a specific torque

value which is lower than 15 Nm the installer should follow the

torque value which ever is more stringent. A calibrated torque

wrench must be used. Mounting systems should be evaluated

for compatibility before installing specially when the system is

not using Clamps or clips. Please contact Maxeon for the

approval of the use of non-standard pressure clamps or clips

where torque values are higher than otherwise stated.

Minimum clamp width allowance is ≥35mm, and for corner

clamping the minimum clamp width is: ≥50mm. Clamps should

not be in contact with the front glass and clamps should not

deform the frame.

Maxeon does not recommend nor endorse the application on

the modules of clamps which, as part of their grounding or

earthing function, have teeth or claw features (see Figure 2)

which may, individually or cumulatively, cause the module

breakage due to (and without limitation):

i) the grounding features touching the front glass which is

incorporated into the module due to the position of such

grounding feature,

ii) the shape, the position or the number of the grounding

features deforming the module top frame, or

iii) the clamp being over-torqued during the installation.

Force must not deform

top frame flange or

glass may break

Force has

to be

applied in

line with

frame

wall

Figure 1a: Clamp Force Locations

Loading...

Loading...