1728 Orbit Way - Minden, Nevada 89423 P: 775-782-1700 F: 775-782-1701 info@maxtonvalve.com www.maxtonvalve.com

98

\\SERVER\CATALOG2019\2019CatalogRev2

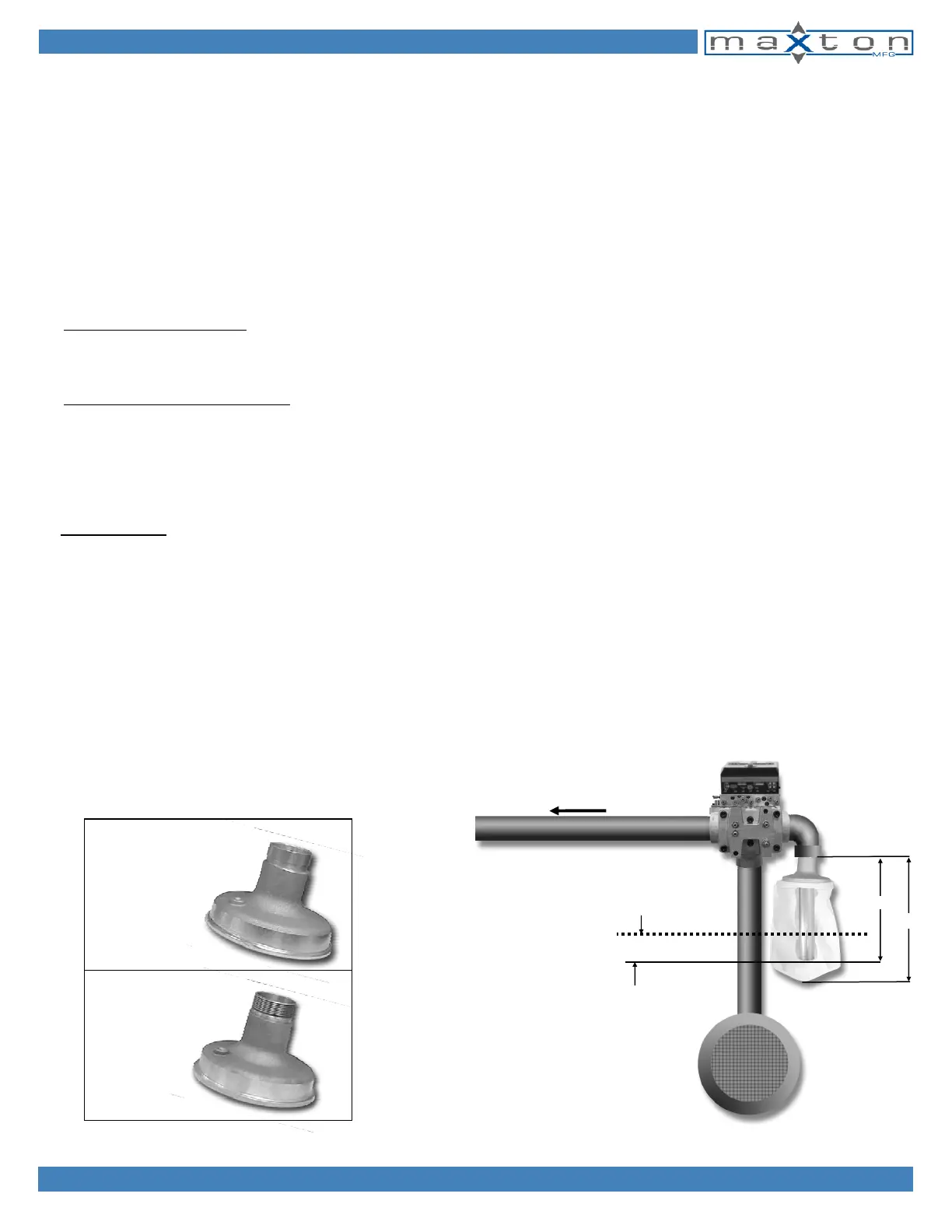

The Tank Discharge Filter (TDF) is a simple yet effective hydraulic elevator oil filter system that removes

contaminants down to 5 microns. The TDF system mounts vertically on the valve/tank discharge line as

shown below (image bottom right). The filter bag is designed for easy replacement when dirty to maintain a

clean, well performing, hydraulic system (see TDF usage below).

The TDF system can be applied to all Maxton commercial elevator control valves (UC1/1A/2/2A and UC4/4M/

MR) as well as other commercial valves on the market using a 2 inch connection. When an elevator system

flow goes beyond 250 gpm multiple filters can be put together, accommodating more flow, using a manifold

arrangement. In this case make sure installation allows room for proper filter bag operation (expansion of

filter bag) with complete clearance.

TDF usage and maintenance recommendations:

Clean System Definition – This can be described as a completely new hydraulic elevator installation with new

oil. Maxton recommends checking the TDF quarterly to maintain optimal elevator performance. Filters need

replacing when white bag color turns brown/black to maintain a clean system.

Non-Clean System Definition – This is an elevator system in use without an oil filtration device. Maxton

recommends installing the TDF and running the pump (no coils energized) for several minutes to filter the oil

in the system. Note: If the TDF captures a substantial amount of contaminants (white bag turns brown/black

in color) during this process then Maxton recommends cleaning the tank, purging or replacing the oil and

replacing the TDF bag. Perform quarterly filter checks to maintain clean oil for optimal elevator performance.

Available in:

2” Grooved

2” Threaded

Specifications

Max. flow per filter (TDF1 / 1V)…….….125 gpm

Weight (TDF1 / 1V)……………………. 5.00 lbs

Max. flow per filter (TDF2 / 2V)………. 250 gpm

Weight (TDF2 / 2V)……………………. 5.95 lbs

Max. operating pressure…………….... 5 psi

Max. operating temperature………..….150° F

Line connection, tank………………….. 2” NPT or Grooved

Oil type………………………………..… Hydraulic Fluid

Fully expanded bag diameter……...… 10 in.

Height (TDF1 / 1V) ……….…………... (A)15” Pipe, (B) 20” w/ bag

Height (TDF2 / 2V) ………………….…(A) 22” Pipe, (B) 28” w/ bag

Filter bag rating………………………... 5 Micron

2” Below

Min. Oil Level

Tank

Jack

UC4M SHOWN

Minimum Oil Level

TANK DISCHARGE FILTER (TDF)

A

B

Loading...

Loading...