4-- 15© 2012 Mobile Climate Control T-299 Rev. 08/2012

4.14 EVAPORATOR BLOWER AND/OR MOTOR ASSEMBLY

4.14.1 GEN 4 Series

Replace the blower motor assembly as follows:

a. Disconnect bus battery.

b. Pop-off the snap cap covers and remove all screws

holding the cover to the unit assembly. Remove

the evaporator cover.

c. Remove drain hoses from drain pan assembly.

d. Remove hardware securing drain pan to the

evaporator assembly (4 places).

e. Supporting the blower motor assembly, remove

the hardware that secures the blower motor

assembly to the evaporator. (4 places).

f. Unplug the motor from the evaporator wiring

harness.

g. Replace as necessary.

h. Reinstall blower motor assembly reversing steps a.

thru f.

i. Check blower motor assembly operation.

4.14.2 GEN 5 Series

Replace the blower wheel and/or motor as follows:

a. Disconnect bus battery.

b. Pop-off the snap cap covers and remove all screws

holding the cover to the unit assembly. Remove

the evaporator cover

c. Disconnect the red and black wire from th e

terminal block.

d. Using a 1/8 inch (EM-1 only) or 3/32 inch

(EM-2/3/7) Allen handle loosen the set screw

securing the motor shaft to the blower wheel. The

set screw can be accessed thr o u gh a no t ch ed fin in

the b lower wheel.

e. Remove hardware (4 places) securing the motor

straptothetoppanel.

f. Remove motor strap and motor gasket from

motor assembly.

g. Slide motor assembly shaft out of blower wheel.

h. Pull blower wheel assembly from bearing cup.

i. Replace motor and/or blower wheel if necessary.

j. Carefully place blower wheel assembly into the

bearing cup.

k. Insert motor shaft into the blower wheel hub.

l. Align blower wheel set screw to flat spot on motor

shaft and tighten.

m.Continue to reassemble by reversing steps a. thru

f.

n. Check motor and blower wheel operation.

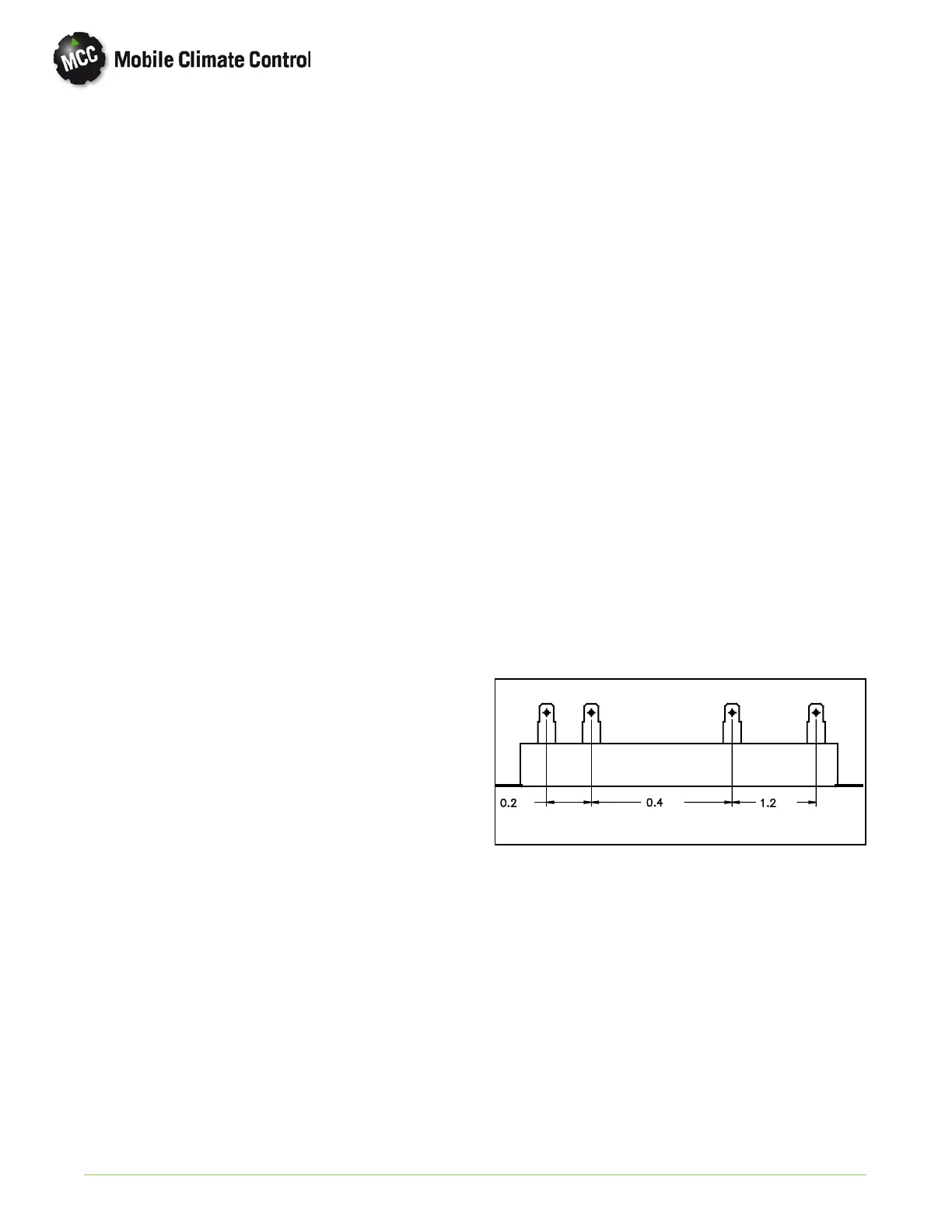

4.15 RESISTORS

4.15.1 GEN 4 Series (Excel)

Low, Medium, High, and High Performance speeds

(for du cted systems) on the GEN 4 series of

evaporators are controlled by the speed selection

switch located on t he drivers control p anel. High

(orange wire) or High Performance ducted (black

wire) speed is determined at time of installation. See

Figure 2-2 for wire connections and Section 5

Electrical for appropriate wiring diagram. Every

GEN 4 series evaporator blower motor assembly has

a speed control resistor. See Figure 4-8 for wire color

connections (speed control) and Ohm's between

prongs.

Total resistance rating of the 4-prong resistor is 1.8

Ohm with a ±5% tolerance rating. Total wattage is

115.

ΩΩ

Ω

Medium

BlackYellow

High High Performance Low

Orange Red

1.8

Ω

Figure 4-8 GEN 4 Series Resistor Assembly

4.15.2 GEN 5 Series

GEN 5 evaporator motor speeds can be controlled

by the driver three ways:

1. Standard GEN 4 type operation usin g the 3 speed

switch and resistors.

2. Variable speed switch control.

3. Electronic Total Control.

Refer to Section 2, GEN 5 Operating Instructions

and Section 5, Electrical, for the appropriate GEN

4/5 wiring diagram.

Loading...

Loading...